Electronic cloth defect segmentation method

A technology of electronic cloth and defects, applied in image analysis, image enhancement, instruments, etc., can solve the problems of inaccurate defect positioning and inaccurate segmentation, and achieve the effect of enhancing contrast, accurately segmenting, and suppressing background texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

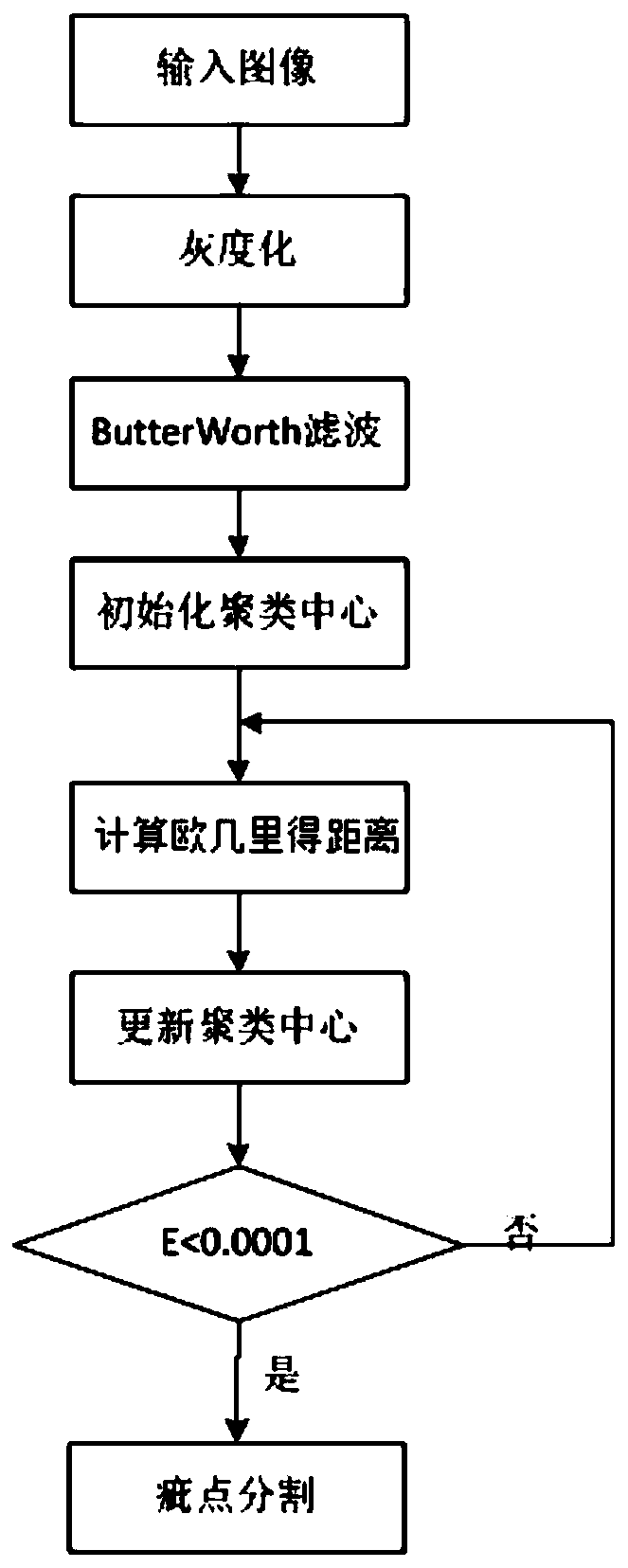

[0044] A method for segmenting electronic fabric defects in the present invention, such as figure 1 As shown, the specific steps are as follows:

[0045] Step 1, converting the electronic cloth image to be detected into a grayscale image;

[0046] Step 2, carry out ButterWorth filter processing to gray scale image, obtain the image after filtering;

[0047] The specific process is:

[0048]Step 2.1. Let the grayscale image obtained in step 1 be f(x,y), the size of the grayscale image is M×N, and the grayscale image f(x,y) is transformed by Fourier to obtain the image F(u,v ), the background of the grayscale image f(x, y) is located in the low-frequency component of the frequency domain, and the noise and image details in the grayscale image f(x, y) are located in the high-frequency component of the frequency domain;

[0049] The formula f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com