Roughness measurement device and method

A measurement device and measurement method technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as low efficiency, measurement results are easily affected by human factors, and are not suitable for roughness measurement of metal sheets, and achieve high efficiency. High, accurate and reliable measurement results, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

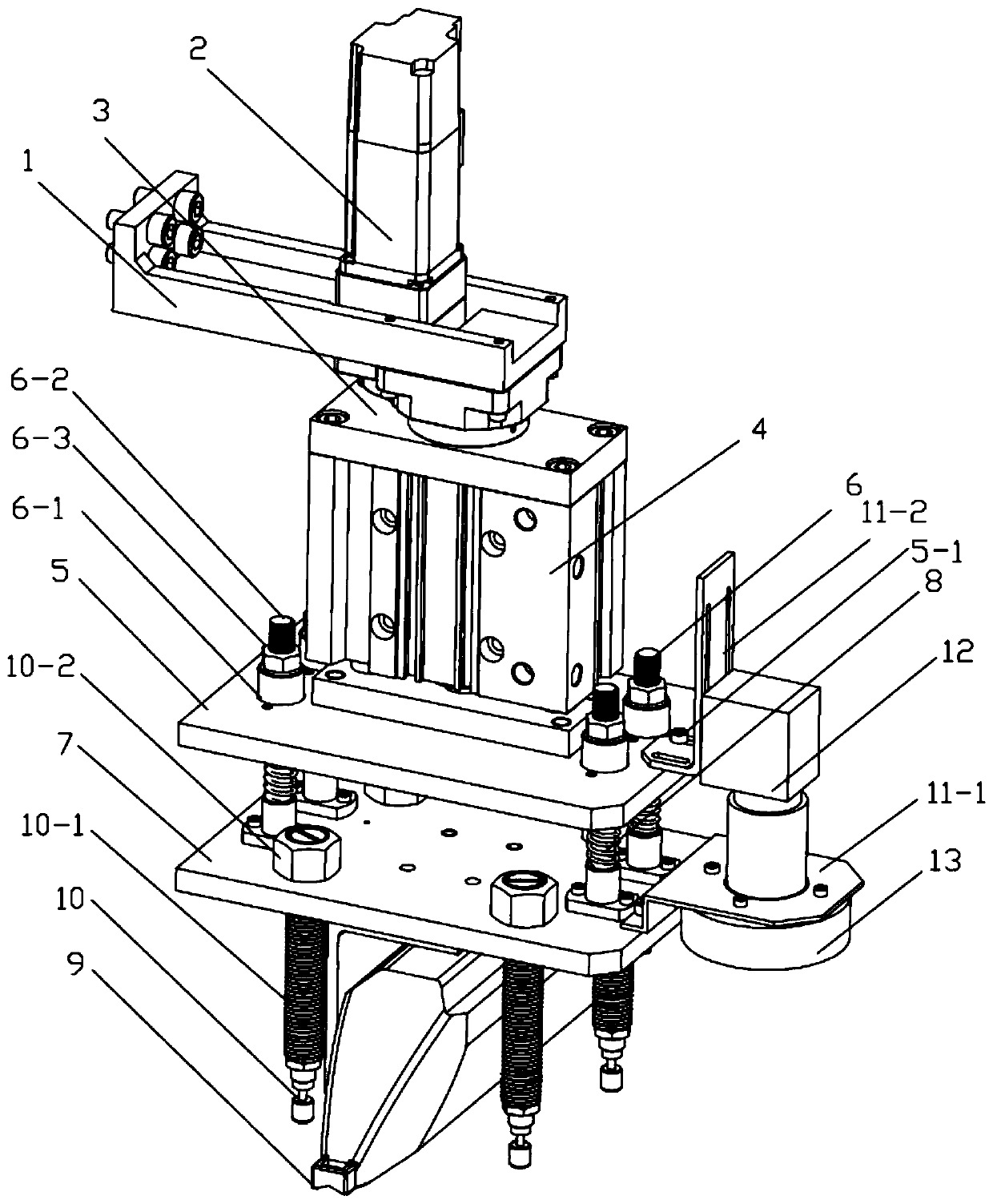

[0020] This embodiment is a roughness measuring device matched with an automatic measuring device for sheet roughness, such as figure 1 As shown, the cantilever-shaped bracket 1 is used to be installed on a planar two-dimensional displacement mechanism, so that the roughness of the required position of the metal sheet can be measured. The support 1 is equipped with a rotary motor 2 with its output shaft facing downwards. Its output shaft is fixedly connected to the cylinder block base 3 equipped with the cylinder 4, and the lower end of the cylinder 4 is fixedly connected to the rectangular upper pressure plate 5, and the upper pressure plate 5 The vertical guide mechanism 6 arranged at the four corners and the lower pressing plate 7 constitute a vertical moving pair. Specifically, the vertical guide mechanism 6 includes a guide sleeve 6-1 fixedly connected to the upper pressure plate and a guide rod 6-2 inserted therein. The lower end of the guide rod 6-2 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com