Method for producing carrier component, and carrier component and carrier comprising the same

A carrier and component technology, applied in the carrier field of carrier components, can solve problems such as laboriousness and increase component weight, and achieve the effects of suppressing overlapping, eliminating ripples, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

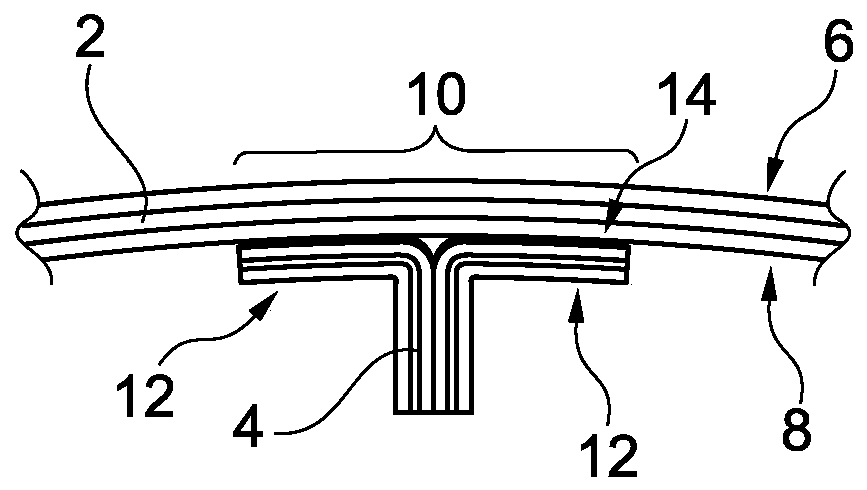

[0038] figure 1 The surface area 2 and the reinforcing elements 4 are shown schematically. The surface region 2 has an outer side 6 , an inner side 8 and a receiving section 10 arranged on the inner side. The reinforcement member 4 is configured, for example, as a longitudinal reinforcement element (stringer) for a watch case of an aircraft. The reinforcing element 4 has only exemplary two legs 12 which provide a segmented connection surface 14 . The connecting surface 14 is in surface contact with the receiving section 10 on the inner side 8 of the surface region 2 .

[0039] Both the surface region 2 and the reinforcing element 4 are produced from fiber-reinforced thermoplastic. The thermoplastic can be, for example, PEEK or PEKK with embedded carbon fibers as reinforcing fibers.

[0040] The reinforcing fibers are only sketched in this diagram. The two components 2 and 4 can be welded together by heating the connection region between the reinforcement component 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com