Automatic fluid polishing machine

A scanning machine and fluid technology, which is used in surface polishing machine tools, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc. cumbersome issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

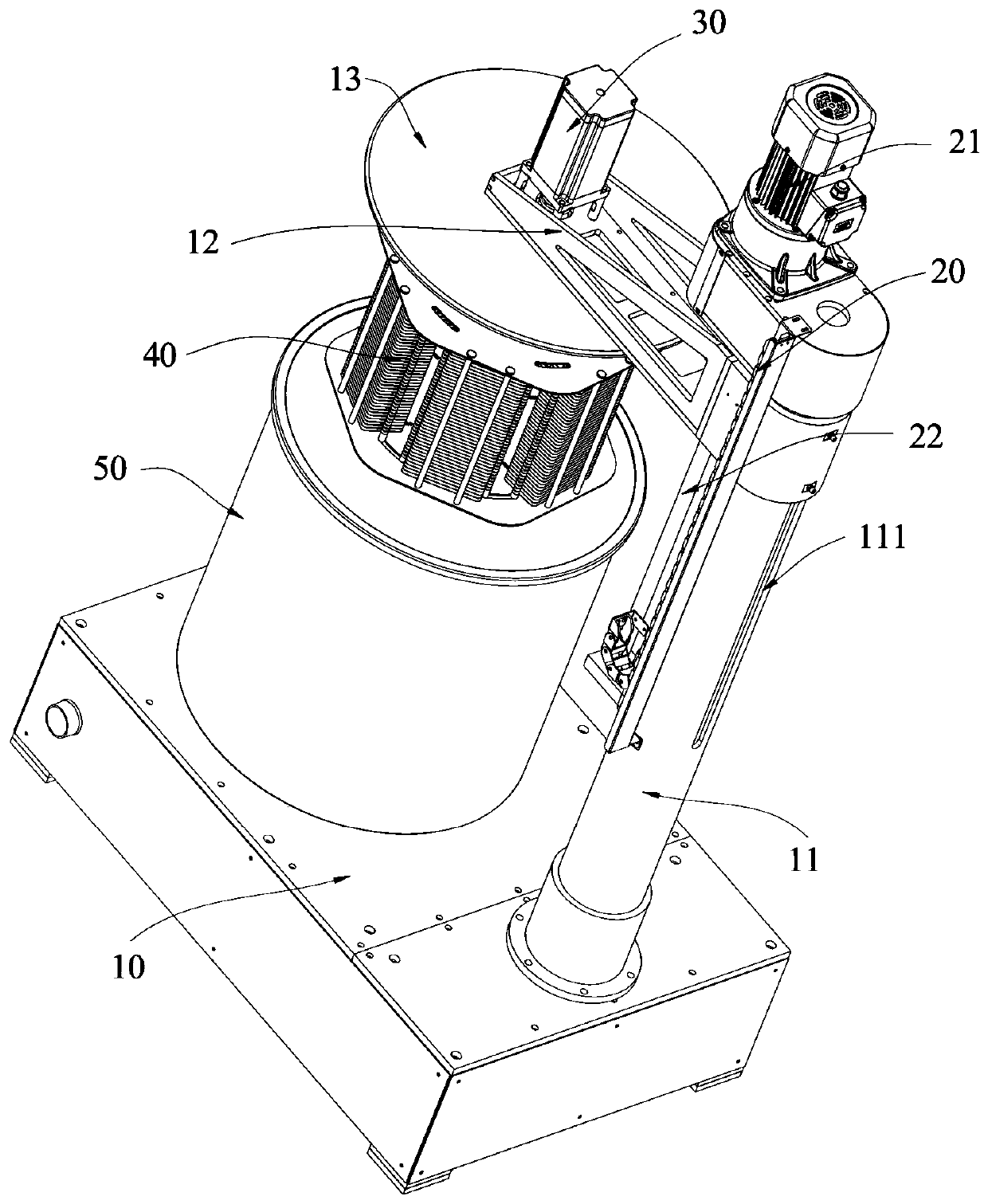

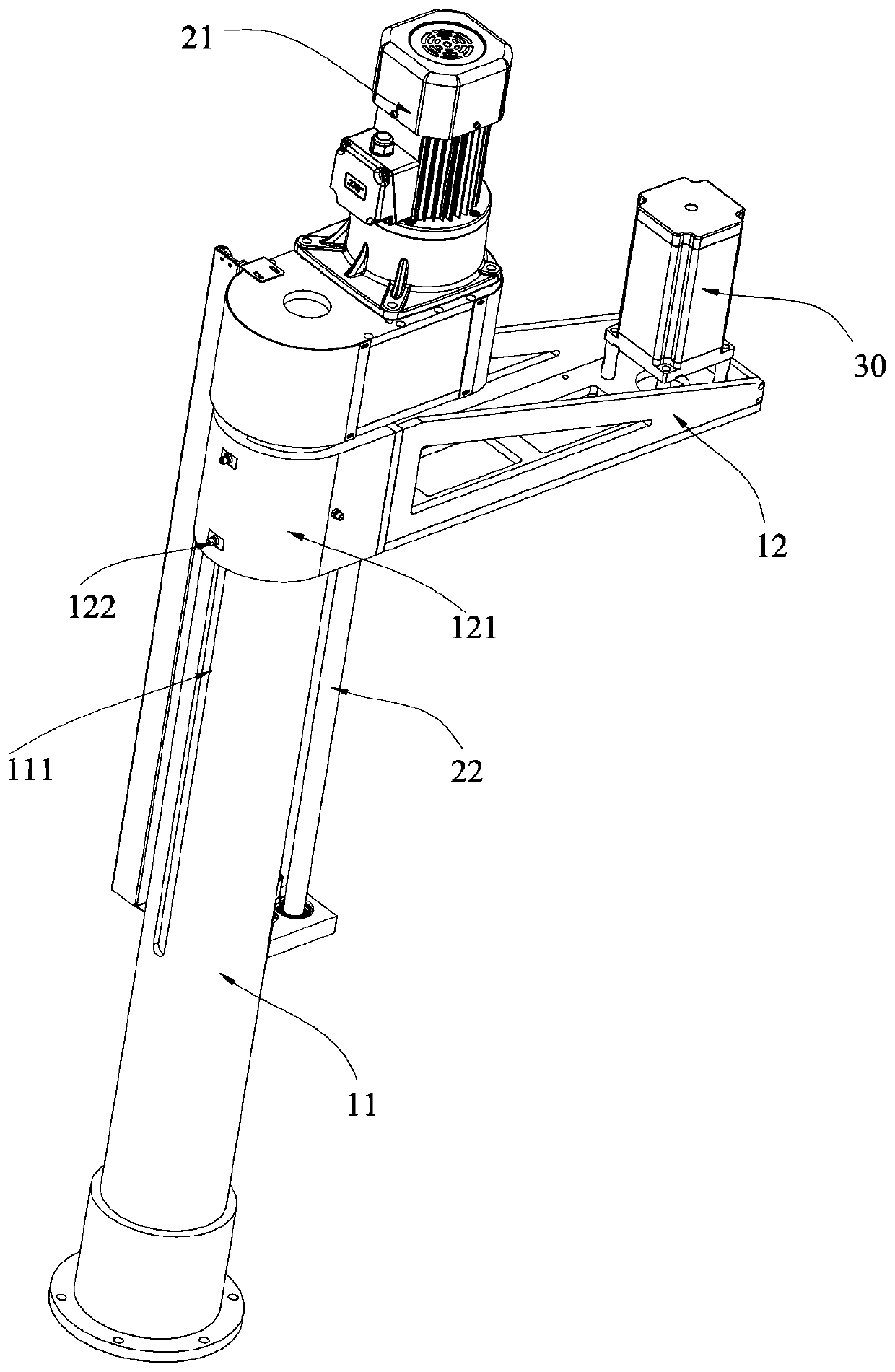

[0029] Such as Figure 1-6 The shown automatic fluid sweeping machine includes a machine body 10, a workpiece insert holder 40, a polishing cylinder 50 and a third drive mechanism. The body 10 is provided with a mounting column 11, and the mounting column 11 is provided with a mounting frame 12 and the first driving mechanism 20 , the mounting bracket 12 can move along the height direction of the mounting column 11 driven by the first driving mechanism 20 . In addition, the mounting frame 12 is provided with a second driving mechanism and a connecting shaft 131 ; the connecting shaft 131 is pivotally connected to the mounting frame 12 , and the connecting shaft 131 rotates driven by the second driving mechanism.

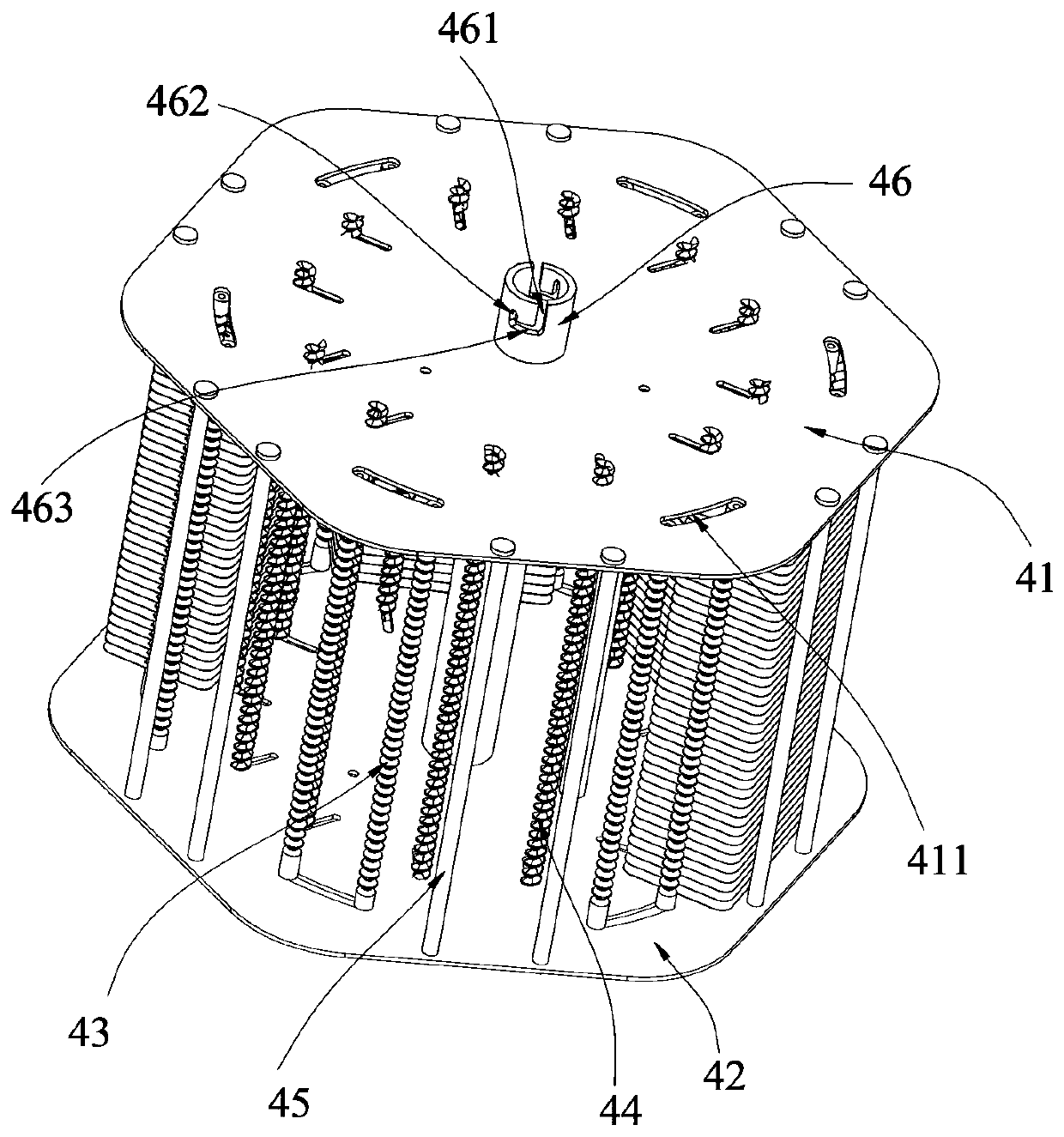

[0030] Specifically, the above-mentioned workpiece inserting frame 40 can be inserted with multiple workpieces, and the workpiece inserting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com