A method for detecting multiple scratches on metal surfaces containing screws

A metal surface and detection method technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve problems such as simultaneous detection, interference, and difficulty in scratch extraction and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

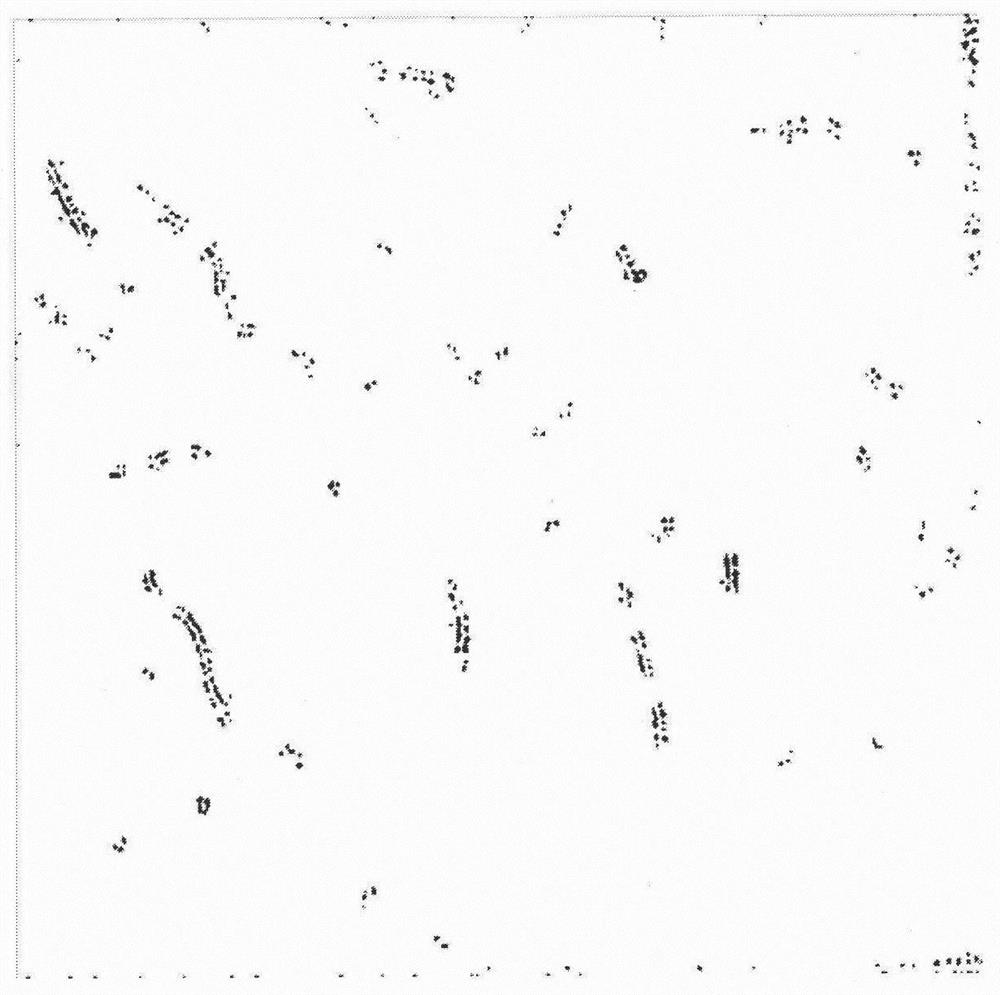

[0025] The image after binarization processing contains useless information such as metal high reflection noise and screw noise interference. It is solved by the present invention to identify the positions of multiple scratches in the original image at the same time through custom filtering and screw removal methods. The problem.

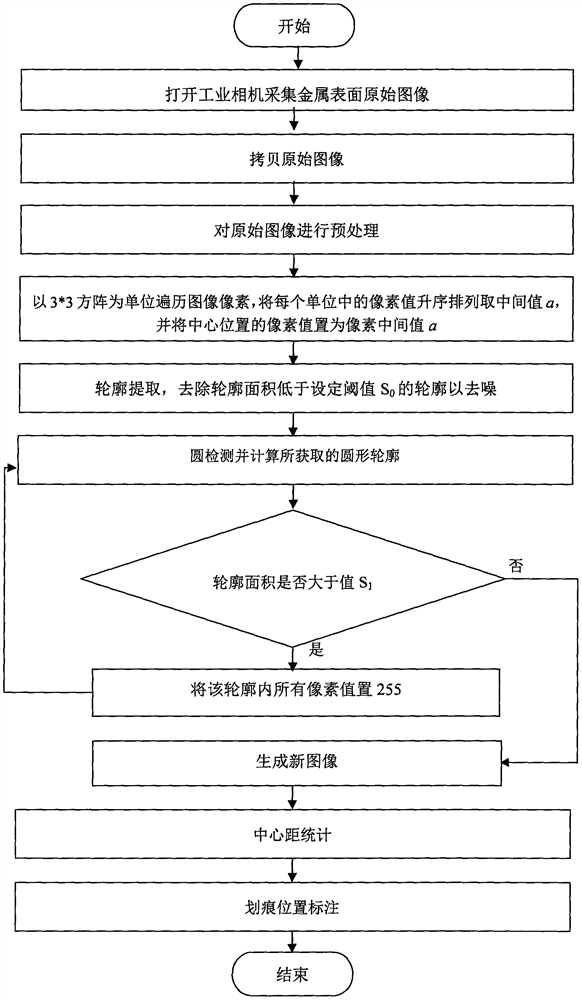

[0026] A method for detecting multiple scratches on a metal surface containing screws is characterized in that the steps are as follows:

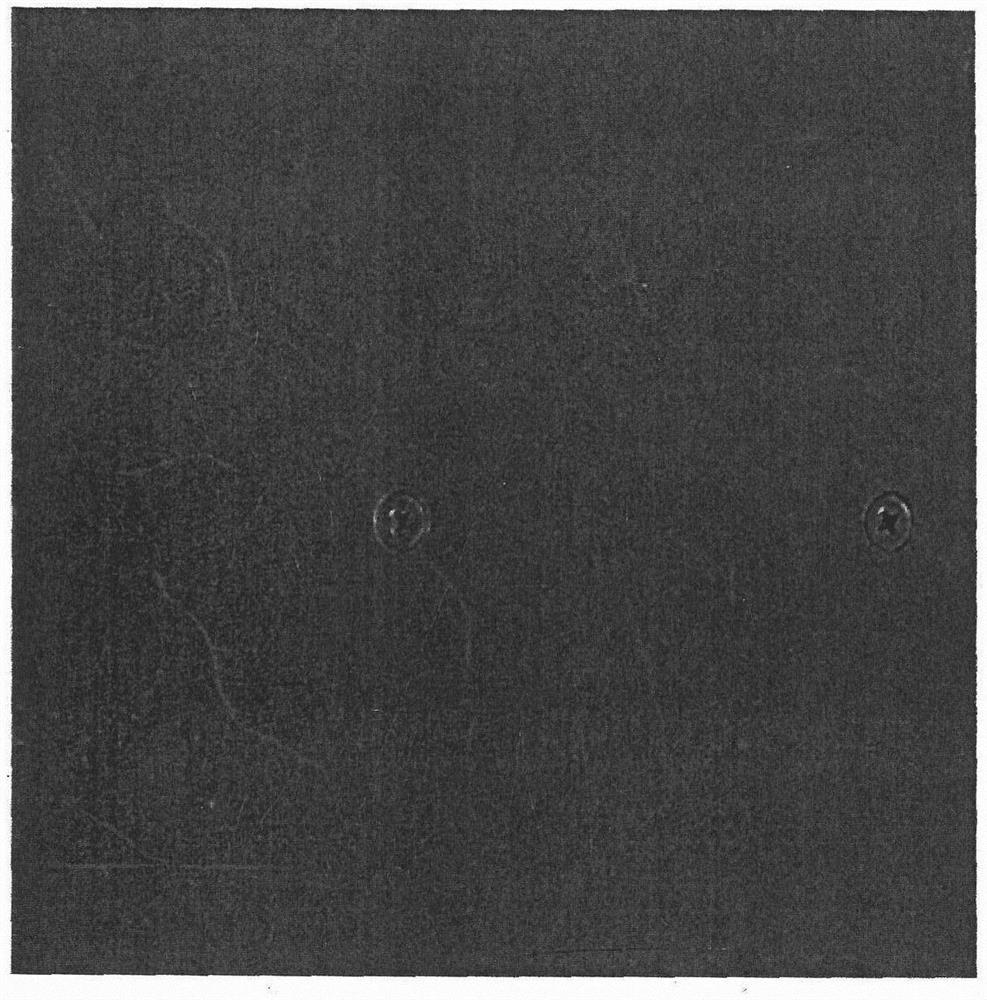

[0027] Step 1: Start the dome light source for the projection light source of the metal to be detected, the industrial camera for image acquisition and the software platform for data processing to obtain the original image of the metal to be detected I 1 ;

[0028] Step 2: To the original image I of the metal to be detected described in step 1 1 Copy to get the metal copy image I to be detected 2 , for the copy image I 2 Carry out grayscale processing, mean value filter processing and binarization processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com