Method for detecting multiple scratches on metal surface containing screws

A metal surface and detection method technology, applied in the direction of measuring devices, optical testing flaws/defects, material analysis through optical means, etc., can solve the problems of scratch extraction and detection difficulty, simultaneous detection, interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

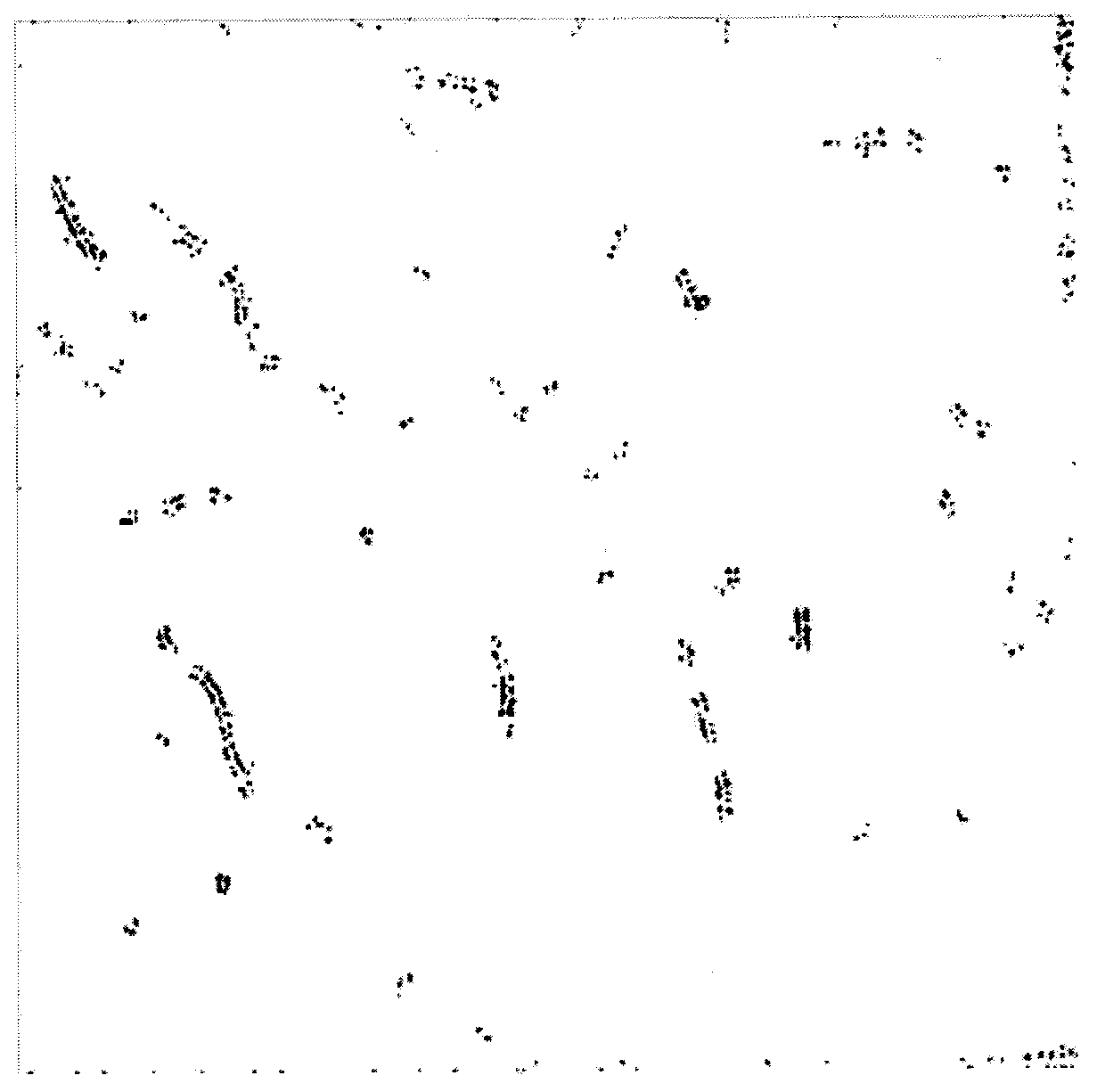

[0032] The binarized image contains useless information such as metal high-reflection noise and screw noise interference. Through custom filtering and screw removal methods, the locations of multiple scratches are simultaneously identified in the original image, which is solved by the present invention. The problem.

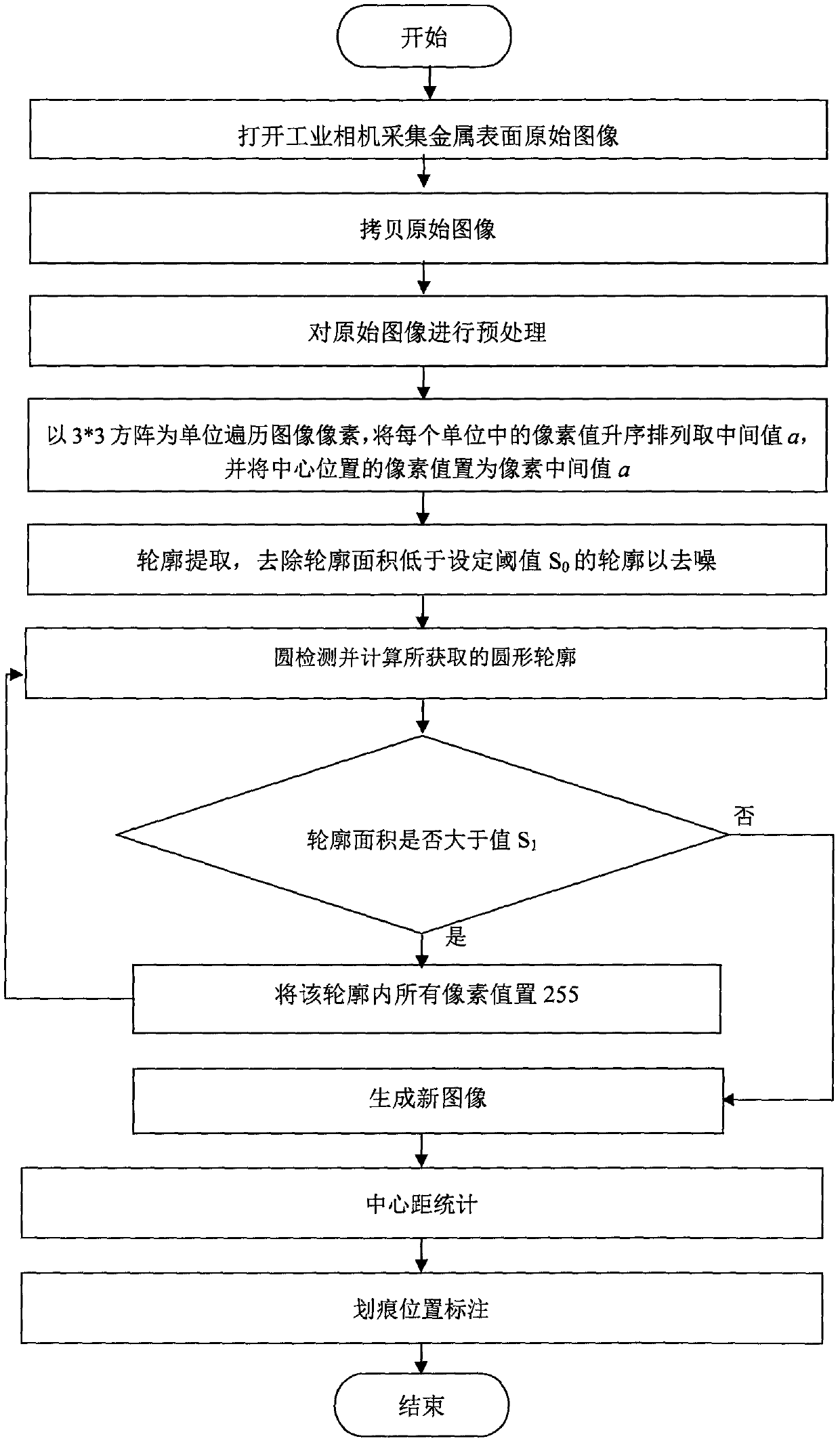

[0033] The present invention provides a method for detecting multiple scratches on a metal surface containing screws. The method can be applied to detecting metal scratches containing screws. The steps are as follows:

[0034] The invention relates to a method for detecting multiple scratches on a screw-containing metal surface, which is characterized in that it includes the following steps:

[0035] Step 1: Start the dome light source for the metal projection light source to be detected, the industrial camera for image acquisition, and the software platform for data processing to obtain the original image of the metal to be detected I 1 ;

[0036] Step 2: For the origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com