Calibration method of laser strapdown inertial navigation system on horizontal three-axis rotary table

A three-axis turntable, strapdown inertial navigation technology, applied in the field of inertial instrument testing, to achieve the effect of improving the accuracy of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: if Figure 1-3 As shown, the calibration method of a laser strapdown inertial navigation system involved in this embodiment on a horizontal three-axis turntable,

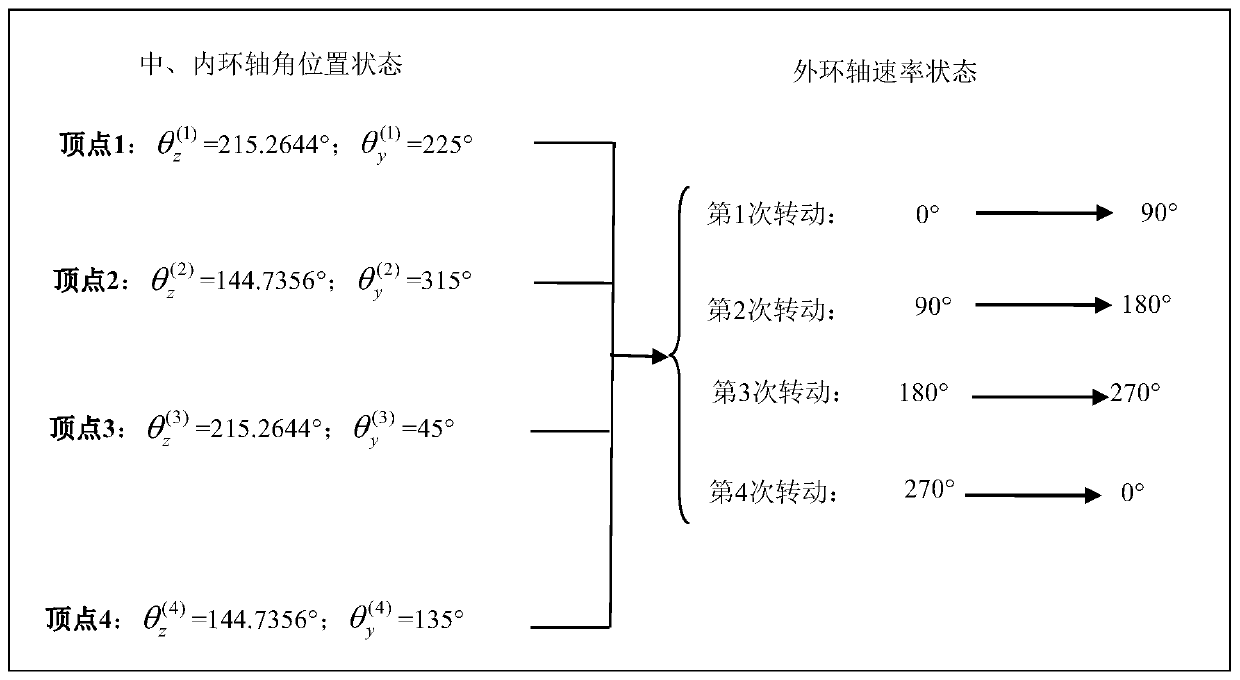

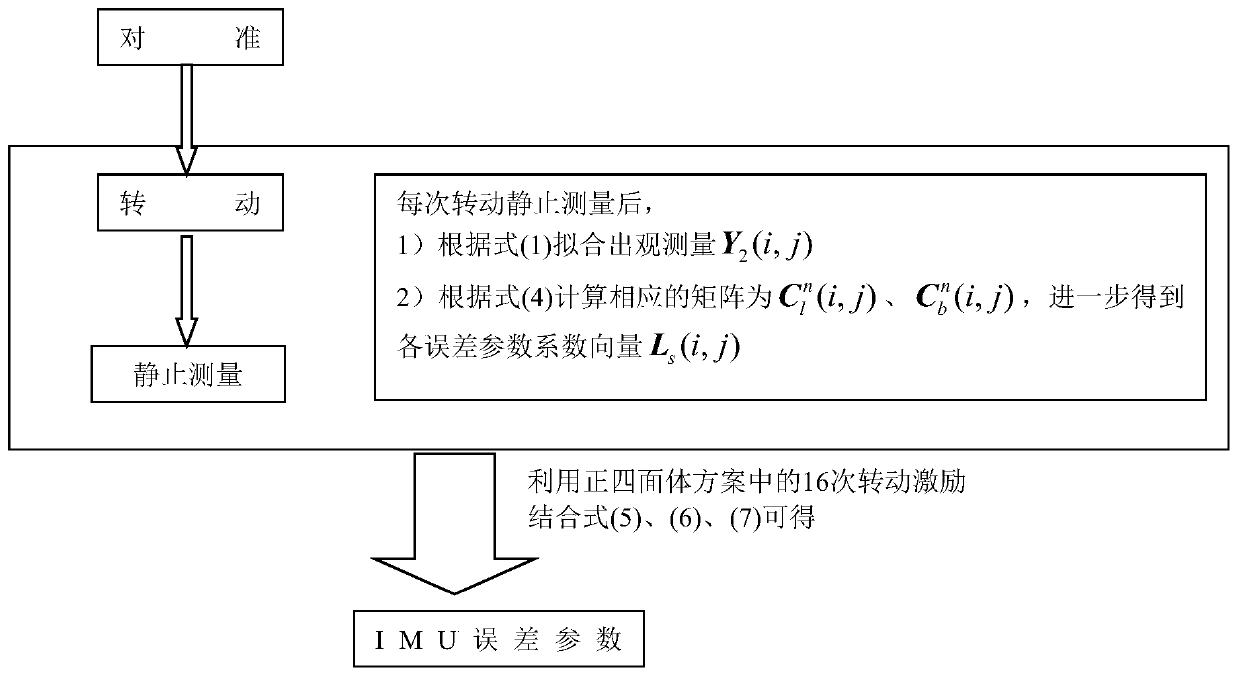

[0030] The laser strapdown inertial navigation system described in the present invention is composed of 3 accelerometers and 3 gyroscopes. Install the laser strapdown inertial navigation system on the horizontal three-axis turntable; use the double-axis position and single-axis rate tumbling method of the horizontal three-axis turntable to realize the regular tetrahedron calibration scheme of the IMU: adjust the middle and inner sides of the horizontal three-axis turntable The ring axis is at four angular positions, so that the angular velocity vectors of the rotation of the outer ring axis point to the four vertices of the regular tetrahedron in the carrier system, and the outer ring axis performs four rotations at equal intervals of 90° at each vertex; through the horizontal The regular tet...

Embodiment 2

[0078] Embodiment two: if Figure 4 with Figure 5 As shown, the calibration method of a laser strapdown inertial navigation system involved in this embodiment on a horizontal three-axis turntable verifies the effect of the present invention as follows:

[0079] The simulation conditions are set as follows: gravitational acceleration g=9.8m / s 2 , the earth's rotation angular velocity ω ie =15.04107° / h, local latitude L=45°; the angular position error of the horizontal three-axis turntable is 1″, the angular velocity of the outer ring axis of the horizontal three-axis turntable is 1° / s, the measurement noise of the accelerometer is 10μg, and the gyro The measurement noise of the instrument is 0.01° / h.

[0080] Table 2 Simulation results of the regular tetrahedron calibration scheme for the laser strapdown inertial navigation system

[0081]

[0082]

[0083] In order to observe the influence of the calibration results obtained on the navigation accuracy of the laser s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com