Central heating system having heat storage function and control method of central heating system

A technology of central heating and control method, which is applied in the field of energy storage, power peak shaving and thermal energy engineering, and energy saving. It can solve the problems of large equipment volume, large floor area, and high energy storage density, and achieve the effect of realizing utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

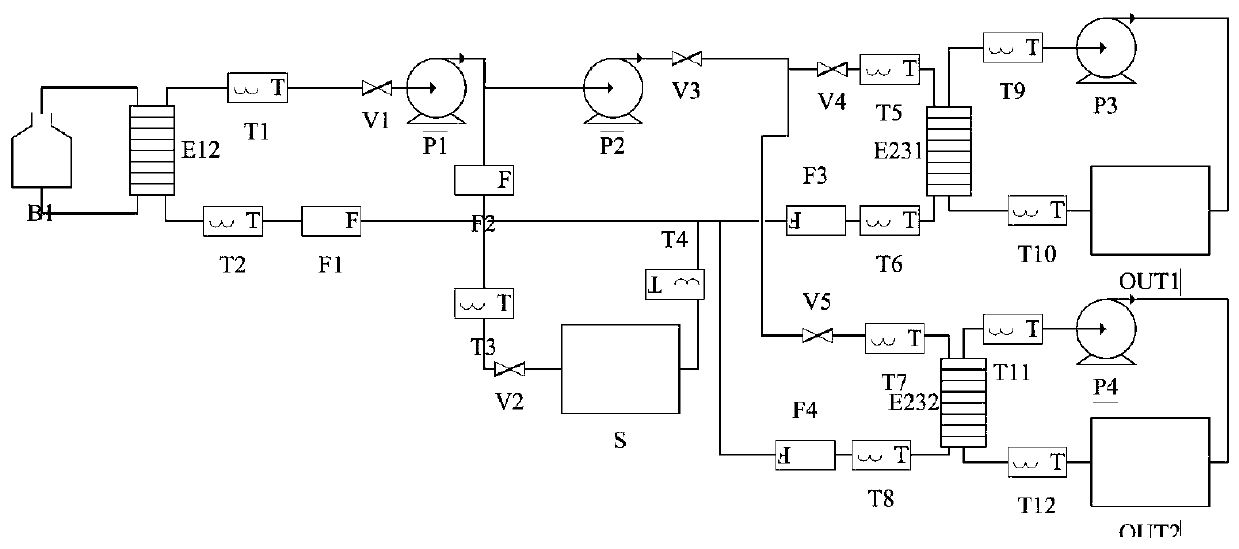

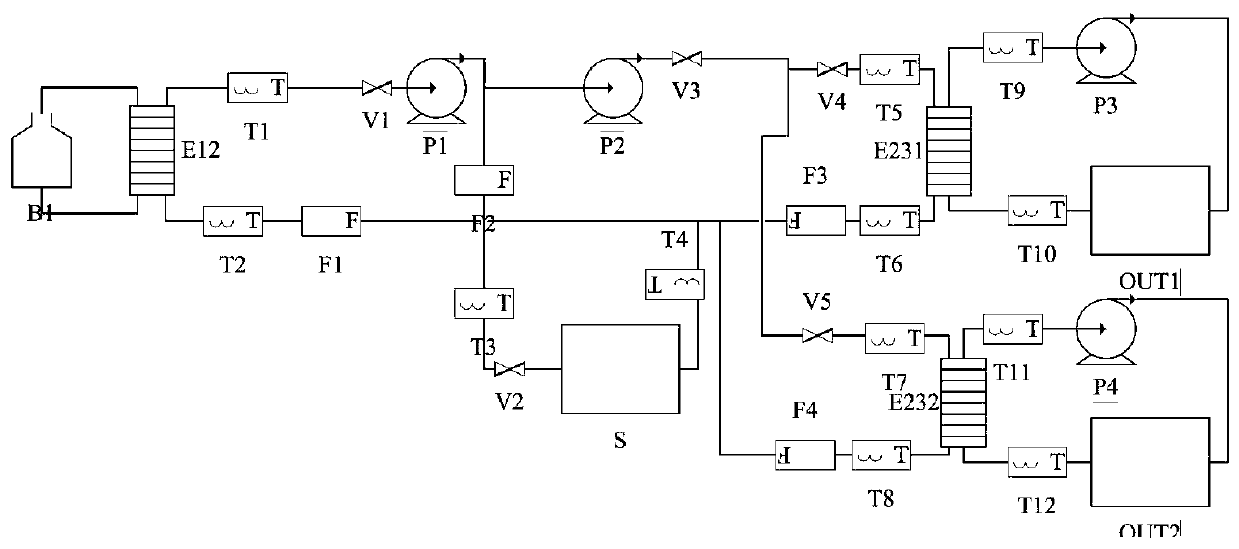

[0024] Such as figure 1 As shown, this example provides a central heating system with heat storage function, which includes an electric boiler system, soft water system, heating pipe network, heat storage system and user-side pipe network. The soft water system and user-side pipe network adopt common settings in this field, and will not be repeated here. This system is mainly improved on the control of heat storage system.

[0025] The electric boiler B1 uses an electrode boiler and outputs power to the secondary side through the plate heat exchanger E12.

[0026] The heat storage module uses the mixed heat storage of the low-temperature phase change material heat storage tank and the water heat storage tank. When the heat storage module is running, the storage temperature range is 45°C to 95°C. The secondary pipe network performs heat exchange.

[0027] The primary side water circuit includes the electric boiler invention B1 invention connected in series, the invention E12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com