Plastic coating and film laminating device

A film-coating and plastic-coating technology, which is applied in textiles and papermaking, fiber raw material processing, paper, etc., can solve problems such as high cost, poor operability, warping of plastic-coated layers, lotus leaves, etc., and achieve high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

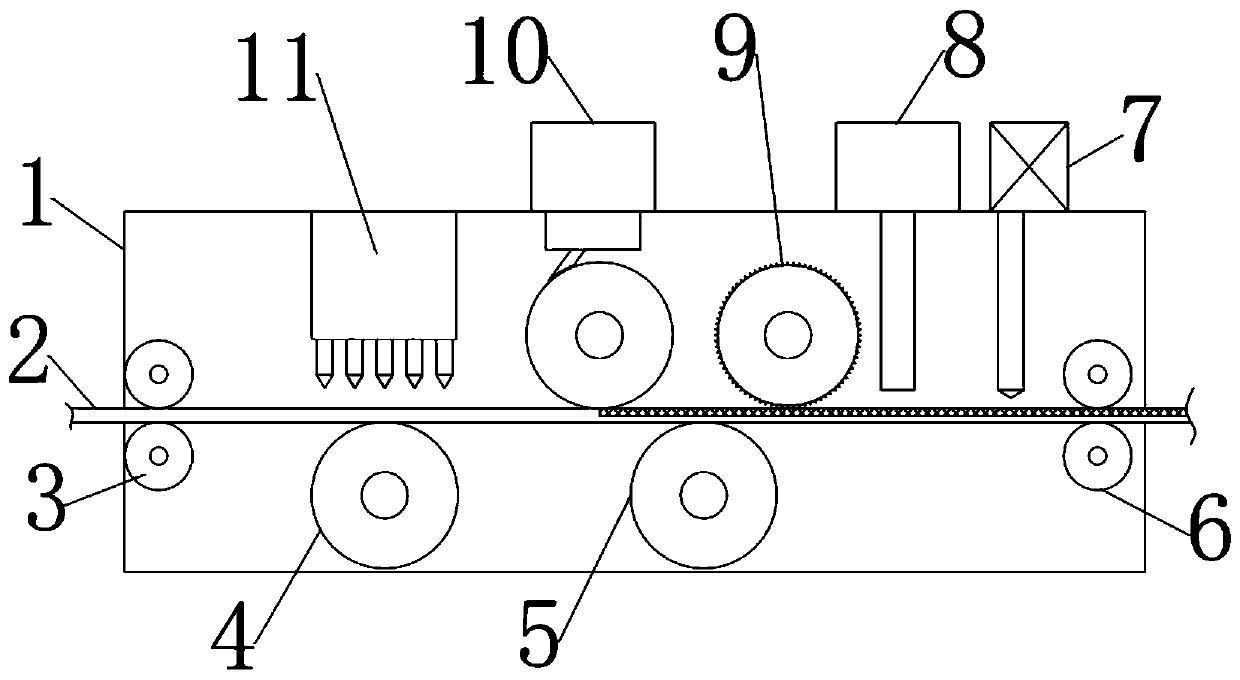

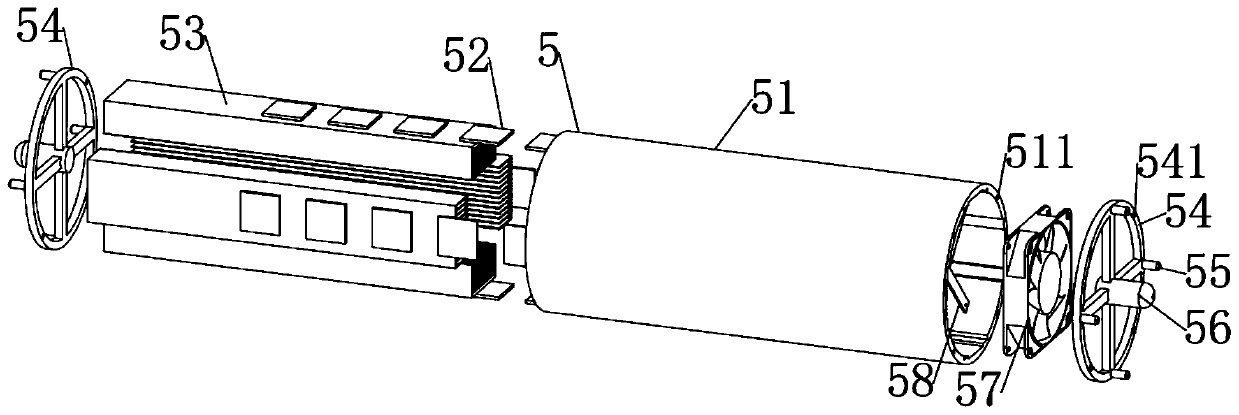

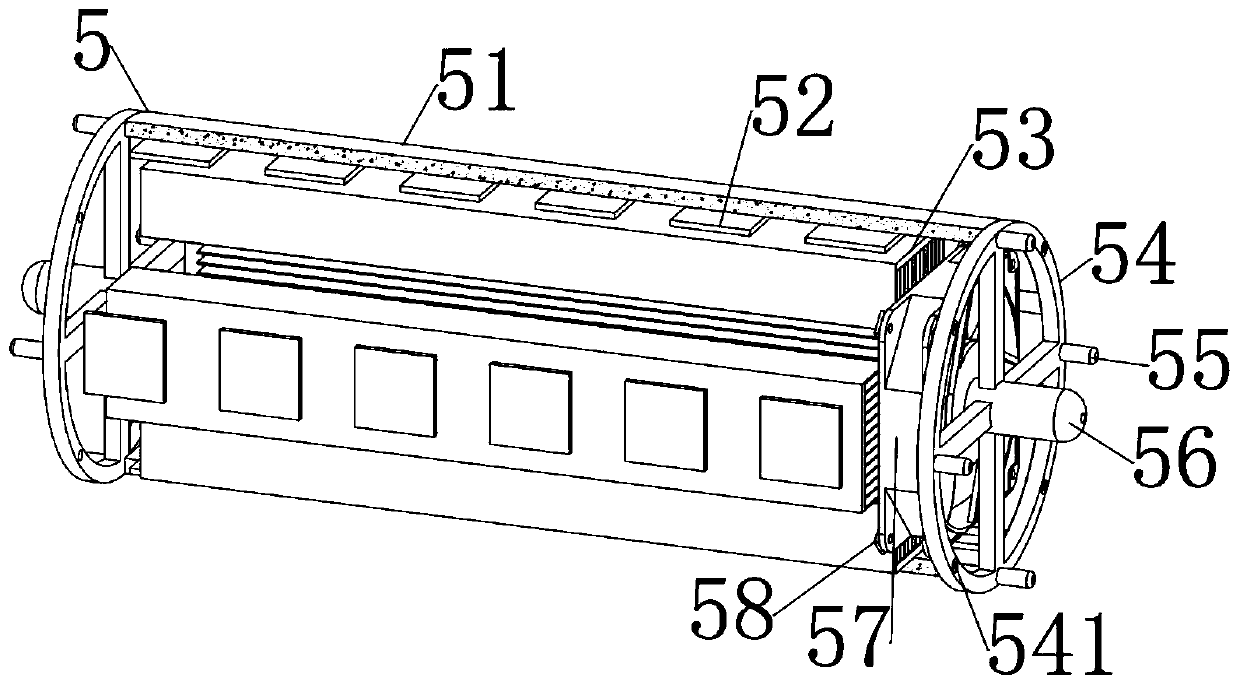

[0027] see Figure 1-5 , in an embodiment of the present invention, a plastic-coating laminating device includes a device main body 1, and the interior of the device main body 1 is sequentially provided with a feeding guide rail 3, a corona device 11, a grounding roller 4, a coating Plastic device 10, cooling roll 5, piercing roll 9, coating device 8, thickness gauge 7 and discharge guide roll 6, and the grounding roll 4 and cooling roll 5 are all arranged below the workpiece 2, and the thickness gauge 7. The coating device 8, the piercing roller 9, the plastic coating device 10 and the corona device 11 are all arranged above the workpiece 2, and the workpiece 2 is arranged between the feeding guide rail 3 and the discharging guide roller 6, and the feeding Both the material guide rail 3 and the discharge guide roller 6 are driven and connected to the drive motor, the thickness gauge 7 and the laminating device 8 are electrically connected to the PLC device, and the side wall ...

Embodiment 2

[0037] see Figure 1-5 , The difference between this embodiment and Embodiment 1 is that a filter screen for blocking dust is provided between the connecting frame, the main shaft 56 and the end cover 54 to prevent dust from entering the inner cavity of the roller 51 and affecting the heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com