Aluminum liquid online refining device

A refining device and aluminum liquid technology, applied in the direction of improving process efficiency, etc., can solve problems such as increased consumption, increased control difficulty, grain refiner, chemical composition of aluminum liquid, and poor temperature uniformity, etc., to reduce the temperature There are effects of loss, shortening of processing time, and resolution of bad characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

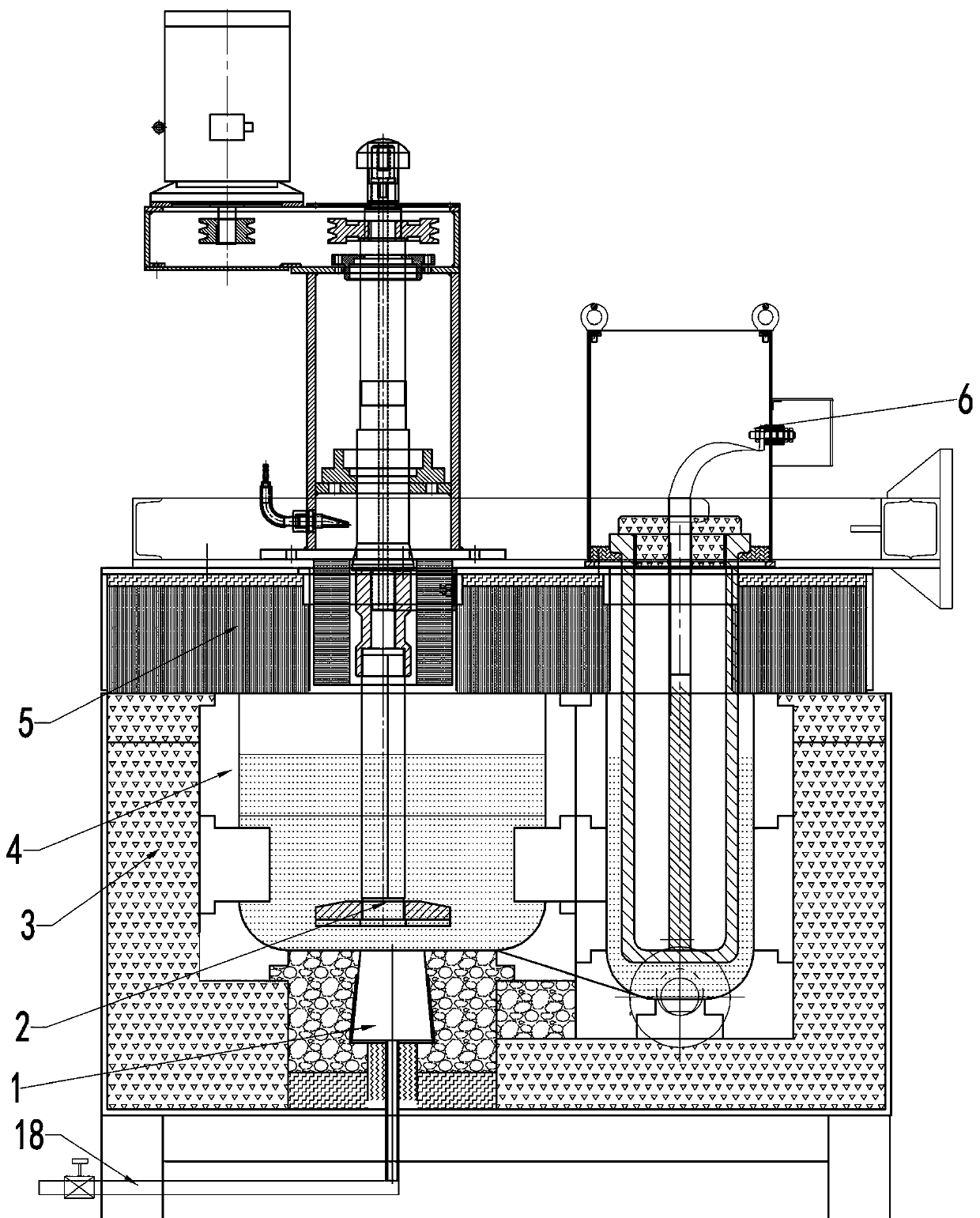

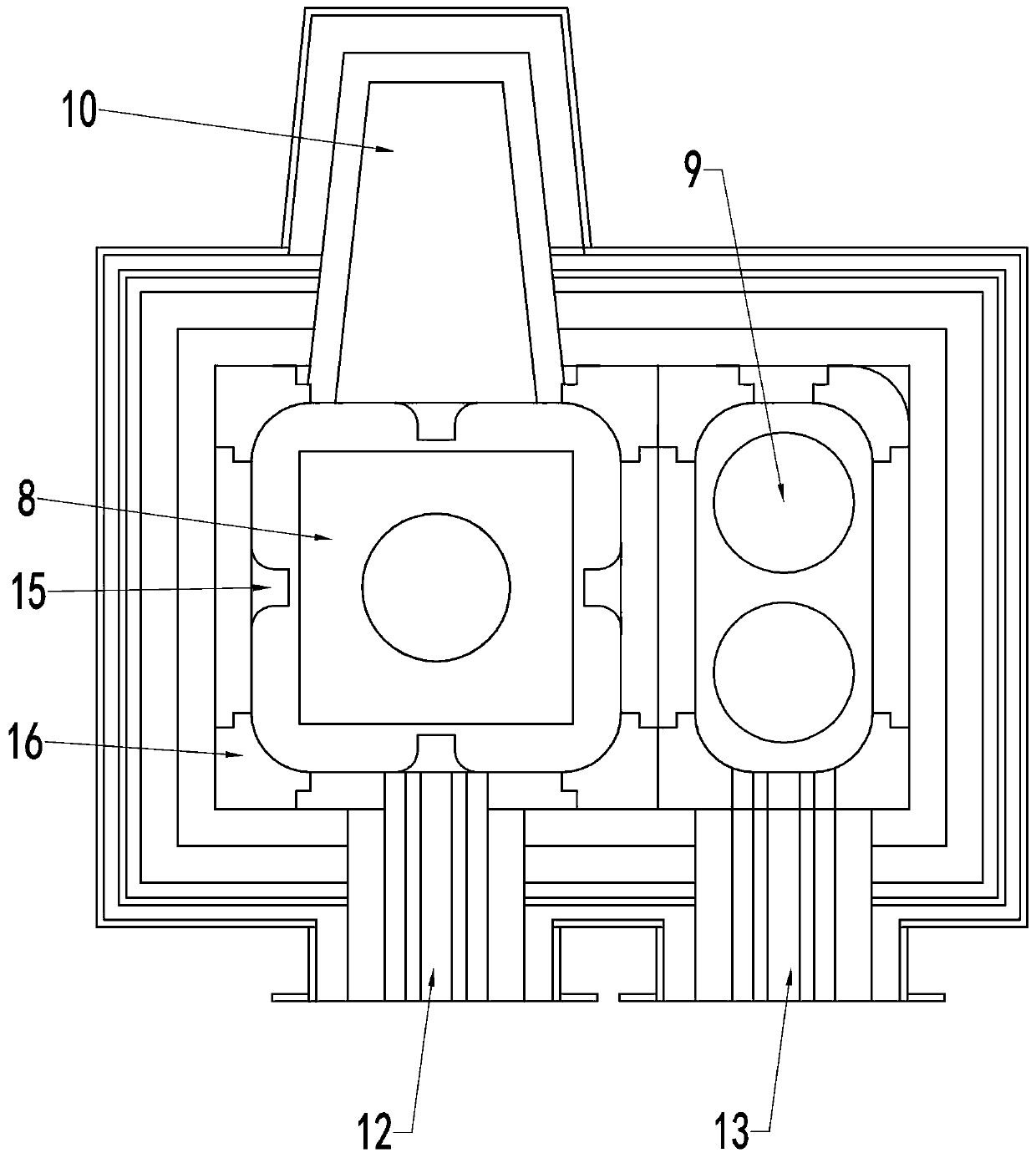

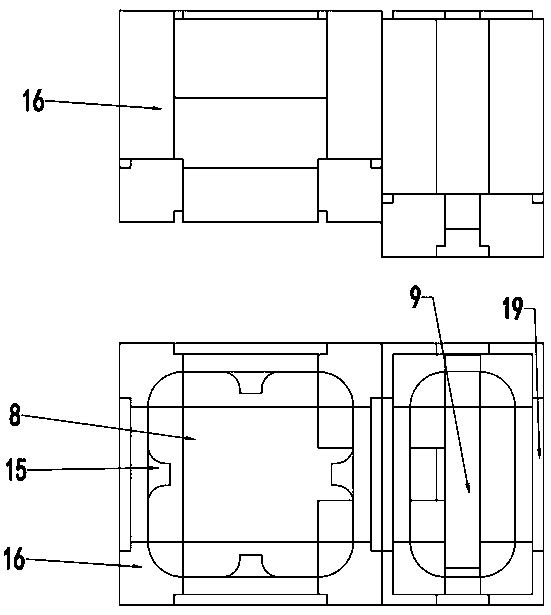

[0027] Such as figure 1 As shown in -5, the present invention is composed of a degassing box 3, an agitator 2, a nano-bubble refining brick 1, and a plug-in heating device 6; ; Flow hole 17 is established between degassing chamber 8 and heating insulation chamber 9; Nano-bubble refinement brick 1 and air supply pipe 18 are installed at the bottom of degassing chamber 8; Air box cover 5 and slag removal port cover 11; Water inlet 12 is installed on the top of one side of degassing chamber 8, and slag removal port 10 is installed on the other side; The water outlet 13 is provided with a diving brick 7; the lower part is equipped with a water outlet 14; the mechanical agitator mechanical stirring system 2 is installed on the degassing box cover 5 corresponding to the upper part of the degassing chamber 8; the aluminum liquid heat preservation and heating device is a plug-in heating device 6, Be installed on the degassing box cover 5 on the top of the heating and insulating chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com