High-efficiency method for synthesizing adamantane

A synthetic method, adamantane technology, applied in the field of catalytic synthesis of fine chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

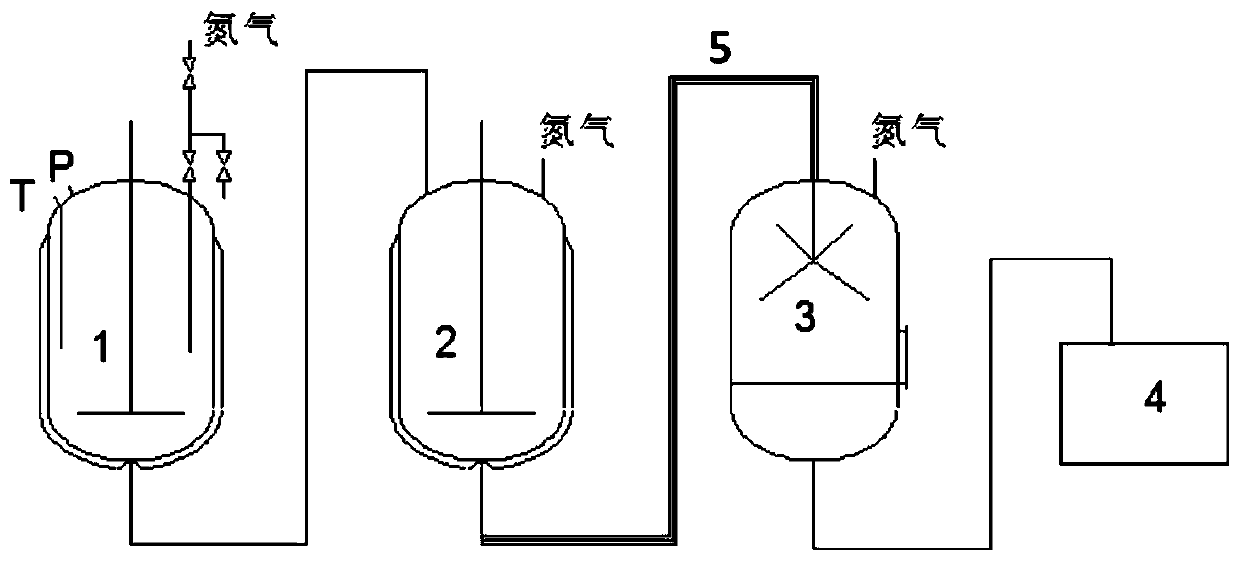

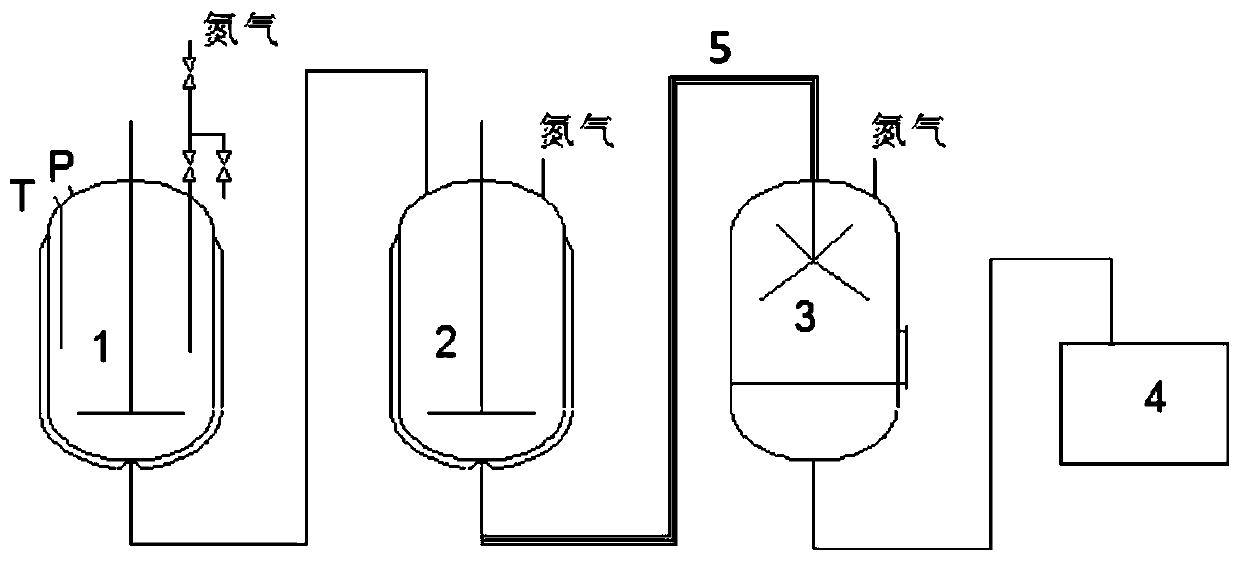

Image

Examples

Embodiment 1

[0018] Add 500 grams of trimethyl phosphate, 5 grams of phosphorus oxychloride, 10 grams of molybdenum chloride, 6 grams of manganese chloride, and 4 grams of iridium chloride into the 1000 ml reactor. After stirring and dissolving, add bridged tetrahydrobicyclic 100 grams of pentadiene, the temperature in the reactor rises to 200 ℃ from normal temperature in two hours, after reacting for 5 hours, sampling analysis, when the adamantane content is greater than 80% (not counting the amount of solvent, auxiliary agent), reduce the reaction temperature to Stir at -10°C for 9 hours, filter and rinse with 50 g of trimethyl phosphate at -10°C, blow the filter cake with air, and dry at 100°C to obtain 62 g of adamantane with a content of 99.1%.

Embodiment 2

[0020] Obtain 590 grams of mother liquor from embodiment 1, add 1 gram of phosphorus oxychloride, 62 grams of bridged tetrahydrodicyclopentadiene, after stirring and dissolving, the temperature in the reactor rises to 200 ℃ from normal temperature in two hours, reacts Sampling and analysis after 5 hours, when the adamantane content was greater than 80% (excluding the amount of solvent and auxiliary agent), reduce the reaction temperature to -10°C, stir for 9 hours, filter and wash with 50 grams of trimethyl phosphate at -10°C, After the filter cake was purged with air, it was dried at 100° C. to obtain 61 g of adamantane with a content of 99.0%.

Embodiment 3

[0022] Add 400 kg of triethyl phosphate, 5 kg of phosphorus trichloride, 14 kg of molybdenum chloride, 4 kg of manganese chloride, and 2 kg of iridium chloride into the 1000-liter reactor. After stirring and dissolving, add bridged tetrahydrobicyclic 120 kilograms of pentadiene, the temperature in the reactor rises to 200 ℃ from normal temperature in two hours, reacts sampling analysis after 5 hours, when adamantane content is greater than 80% (not counting the amount of solvent, auxiliary agent), reduce reaction temperature to Stir at -10°C for 9 hours, filter and rinse with 60 kg of triethyl phosphate at -10°C, purify the filter cake with nitrogen, and dry at 100°C to obtain 75 kg of adamantane with a content of 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com