large oil storage tank

A technology for oil storage tanks and storage tanks, which is applied in the field of petrochemical equipment, can solve the problems of high stress of storage tank wall plates and cracked weld seams, and achieve the effects of reducing bending stress, improving stress, and avoiding welding residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

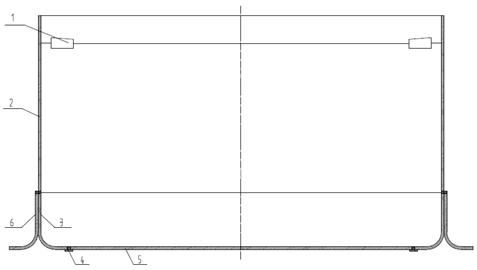

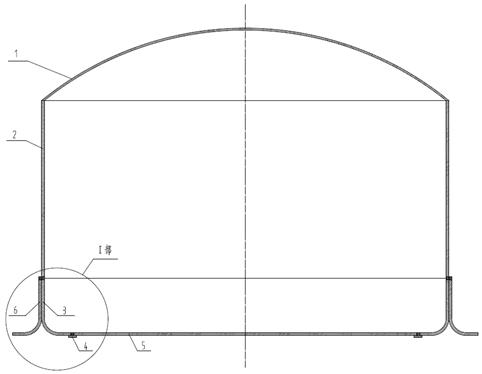

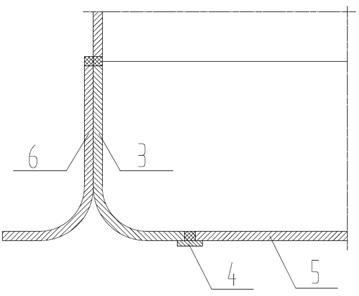

[0022] Such as figure 1 As shown, a large oil storage tank has a tank top 1, a tank wall 2, a tank bottom center plate 5, an "L"-shaped transition connection ring 3 between the tank bottom 5 and the tank wall 2, and the "L"-shaped transition connection The ring 3 has a horizontal annular edge section 31 , an arc-shaped transition section 32 and a vertical cylindrical section 33 , "L" shaped reinforcement ring 6 . The shape and size of the "L" type transition connection ring 3 and the "L" type reinforcement ring 6 are the same.

[0023] The horizontal annular edge section 31 of the "L"-shaped transition connecting ring 3 is butt-welded with the middle plate 5 of the tank bottom, and a backing plate 4 is provided under the butt weld. The vertical cylindrical section 33 of the "L" type transition connecting ring is butt-welded with the tank wall 2 . The vertical cylinder section of the "L" type reinforcement ring 6 outside the tank wall is fillet welded with the tank wall 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com