Torsion beam suspension structure capable of active lifting

A technology of torsion beams and suspensions, applied in the direction of suspensions, elastic suspensions, interconnection systems, etc., can solve problems such as high cost, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

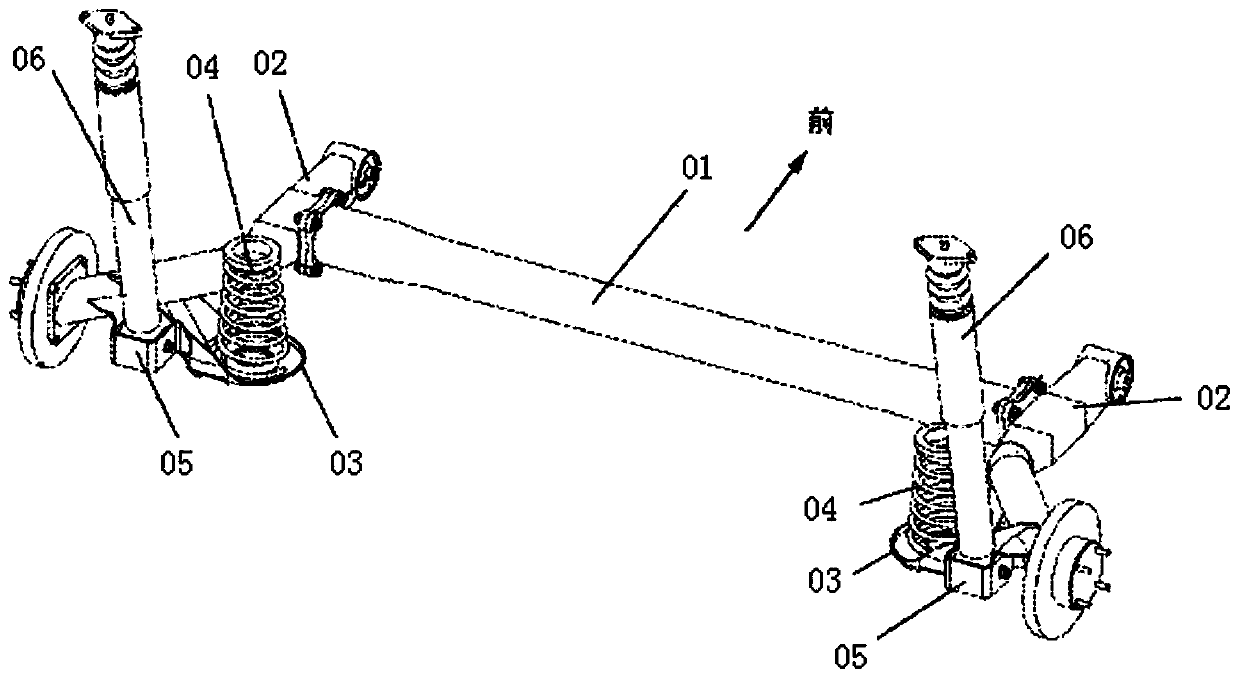

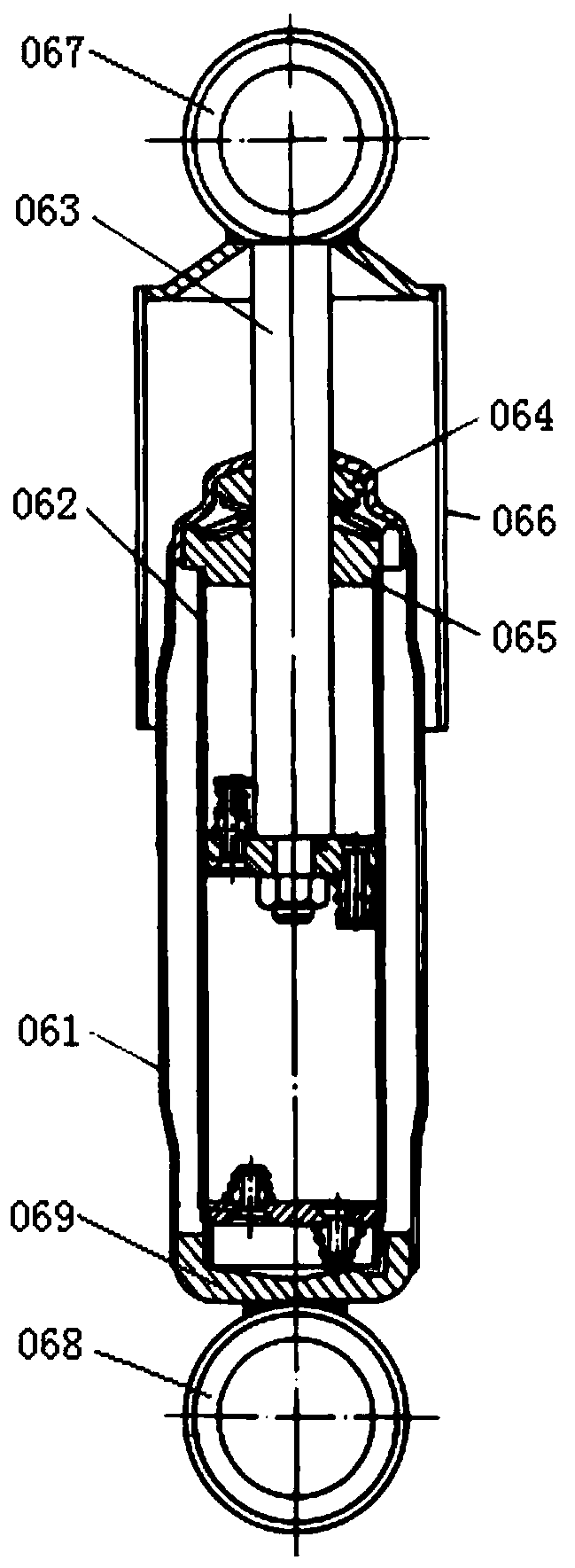

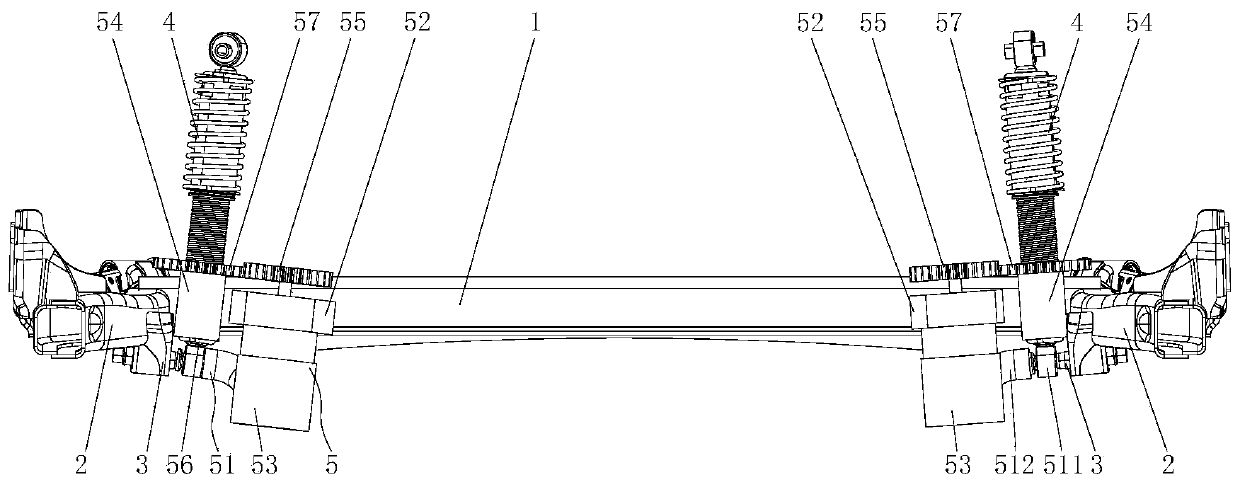

[0031] Such as Figure 1-10As shown in one of them, the active lifting torsion beam suspension structure of the present invention includes a torsion beam 1, two suspension longitudinal arms 2, two shock absorber mounting brackets 3 and two shock absorbers 4, the torsion The beam 1 extends along the vehicle width direction, and the two ends of the torsion beam 1 are respectively connected with two suspension trailing arms 2 extending along the front and rear directions of the vehicle, and the outer sides of the two suspension trailing arms 2 are provided with connecting parts 21 for connecting wheels , the inner sides of the two suspension trailing arms 2 are respectively fixedly connected to one end of the two shock absorber mounting brackets 3, and it also includes a lifting drive mechanism 5 for driving the two shock absorbers 4 to carry out synchronous reverse lifting movement, so The lifting drive mechanism 5 includes two sleeves 51, two drive motors 52, two motor bushings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com