Anti-blocking and cooling device for flue gas inlet of deacidification tower and its use method

A flue gas inlet and cooling device technology, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve problems such as high labor intensity, poor operating environment, and increased sewage volume in the deacidification system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

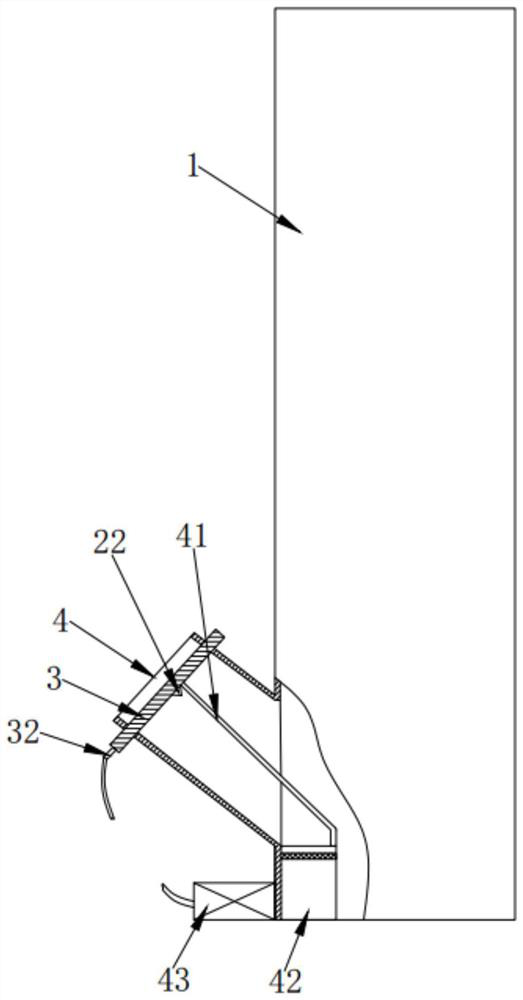

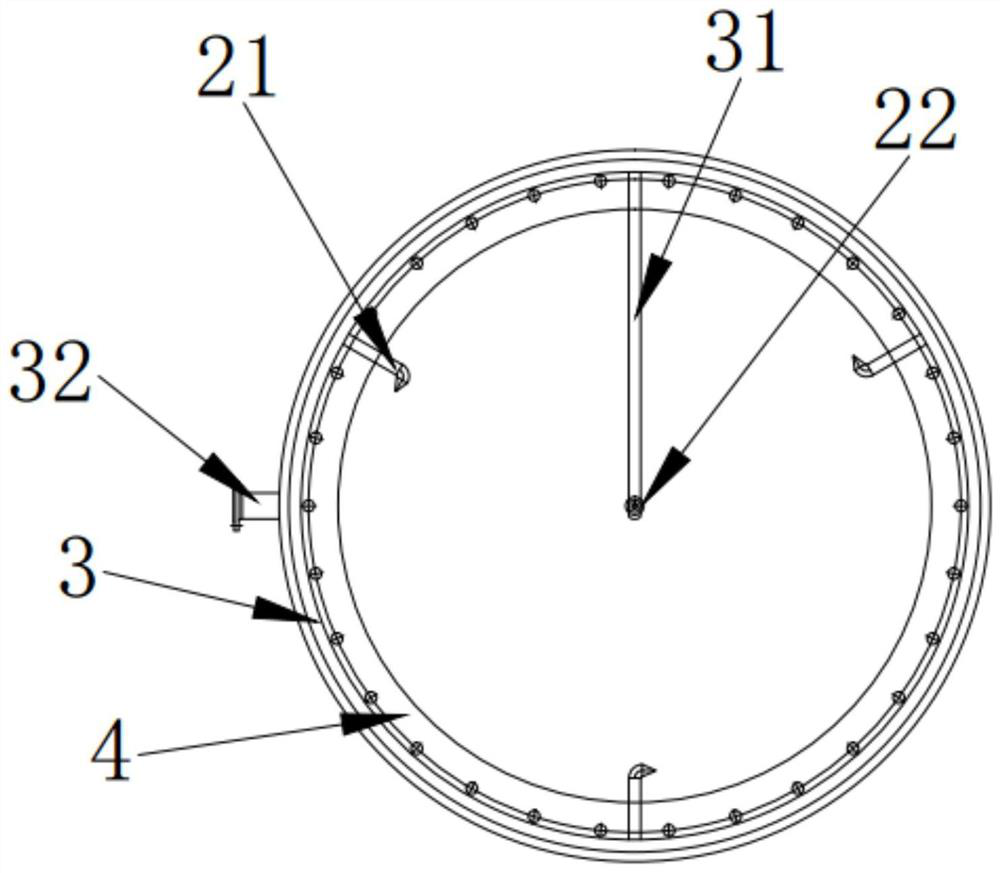

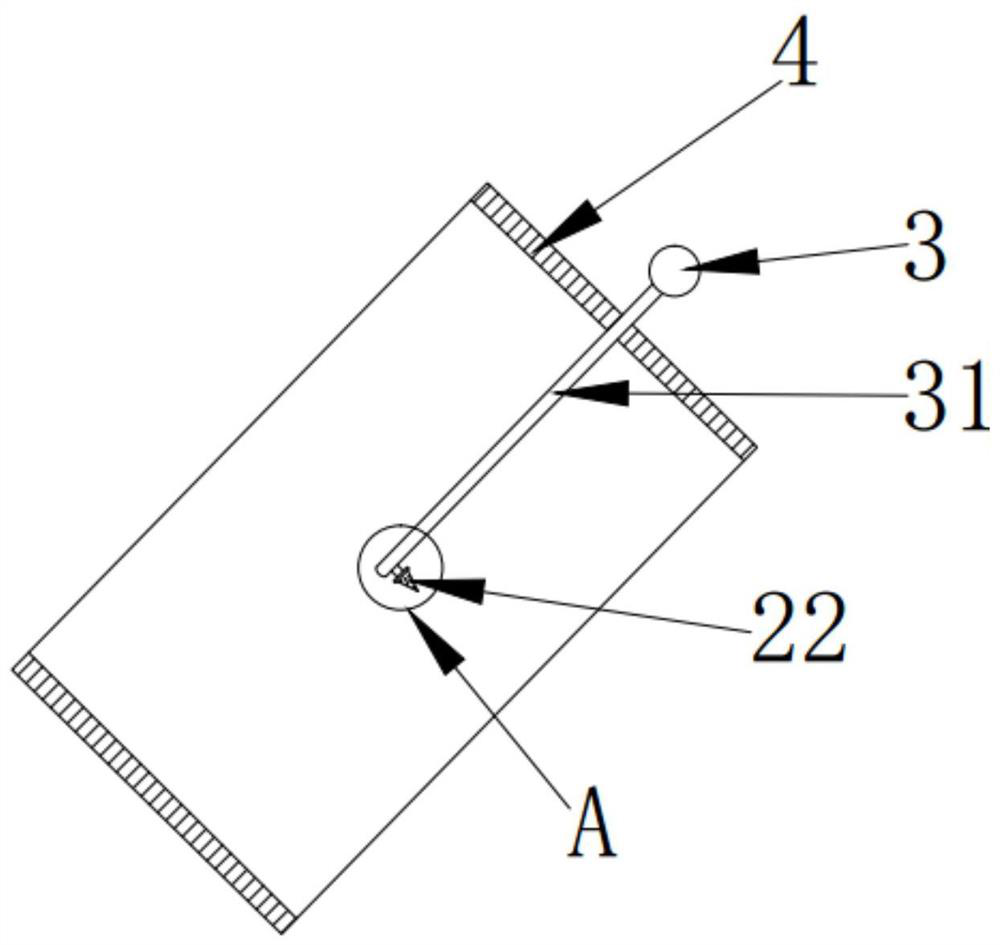

[0020] Depend on figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention is composed of a deacidification tower body 1 and an air inlet 4. At the air inlet 4, three fixed through holes are uniformly wound around the side wall of the inlet position. First nozzles 21 are perforated in the holes, one end of each first nozzle 21 extends into the corresponding position of the air inlet 4, and the other end extends outwards from the corresponding position of the air inlet 4, and is connected with the annular The water pipe 3 is in screw connection, and the axial centerline of the annular water pipe 3 is on the same straight line as the axial centerline of the air inlet 4 . One end of the first nozzle 21 extending into the air inlet 4 is a wedge-shaped structure with a rectangular cross section. The axial centerline of the wedge-shaped struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com