Process for reducing concentration of CO in low-temperature methanol wash tail gas

A low-temperature methanol washing and process technology, applied in the field of coal chemical industry, to achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

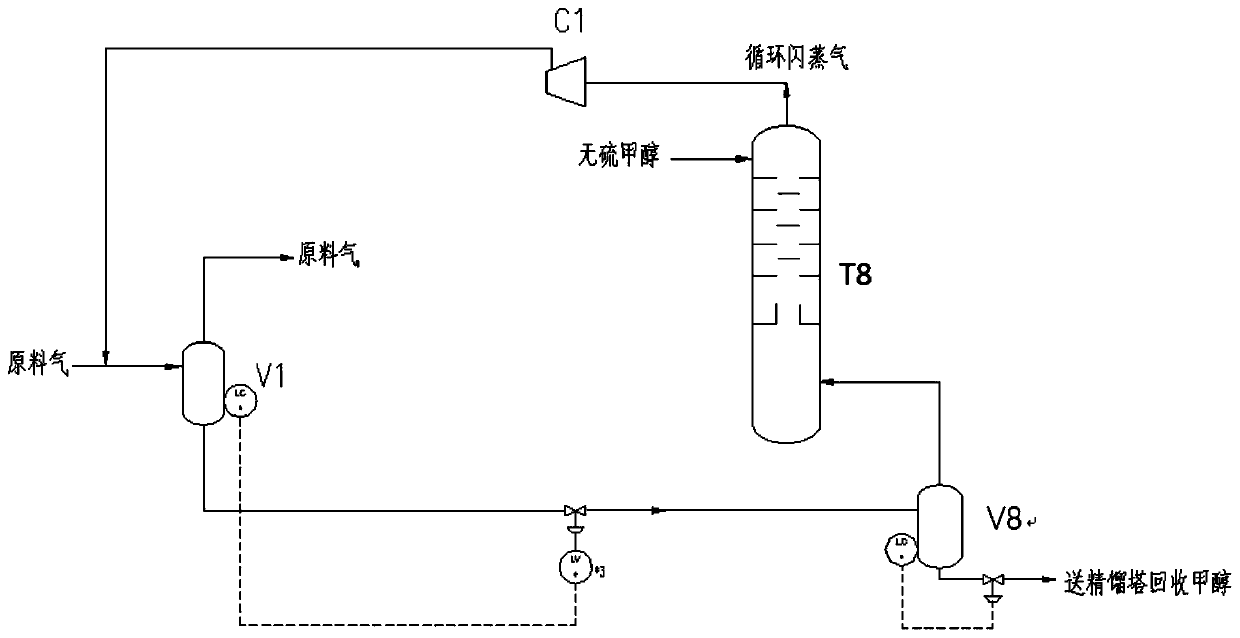

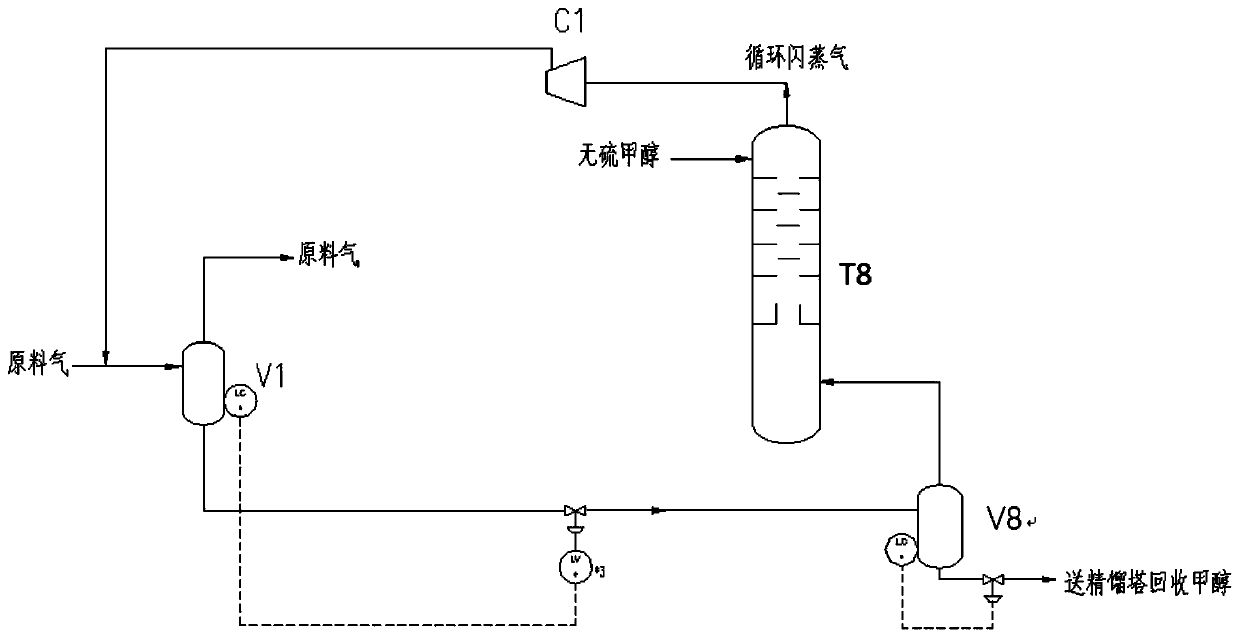

[0029] Example 1 A process for reducing CO concentration in low-temperature methanol scrubbing tail gas

[0030] Take the low-temperature methanol washing section of a 1 million-ton methanol plant as an example: the unit hour flow rate of CO and H2 in the raw material gas of the low-temperature methanol washing section is 275,000 Nm3. The composition of the CO component was 33.3% (V).

[0031] The water-containing feed gas washed with low-temperature methanol (pressure: 5.8MPaG, temperature: -25°C, the main components are CO, H2, CO2 and a small amount of water, methanol) first passes through the separator V1 to separate methanol aqueous solution (pressure: 5.75MPaG, Temperature: -25°C, the components are mainly methanol, water, and a small amount of dissolved CO, H2, CO2), the methanol aqueous solution at the bottom of the separator V1 first heats up to 60°C, and then reduces it to 0.8MPaG through the pressure reducing valve The flash gas sent to flash tank V8, V8 (pressure:...

Embodiment 2

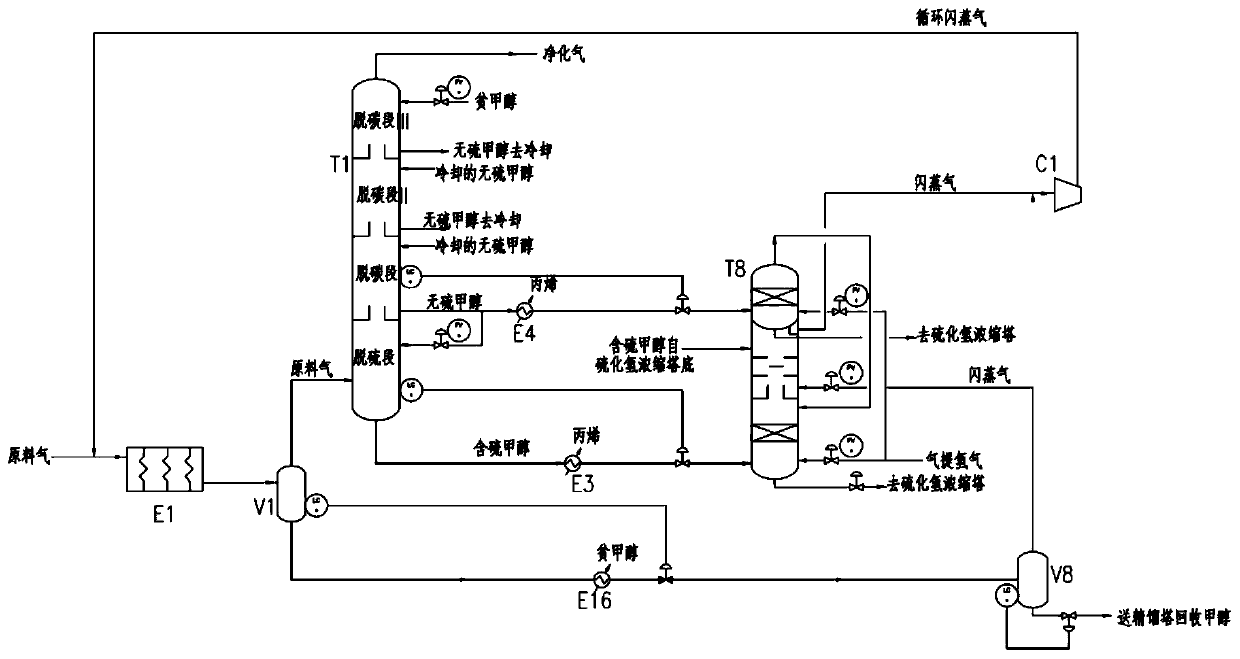

[0033] Example 2 A process for reducing CO concentration in low-temperature methanol scrubbing tail gas

[0034] Take the low-temperature methanol washing section of a 1 million-ton methanol plant as an example: the unit hour flow rate of CO and H2 in the raw material gas of the low-temperature methanol washing section is 275,000 Nm3. The composition of the CO component was 33.3% (V).

[0035] The water-containing raw material gas washed with low-temperature methanol (the main components are CO, H2, CO2 and a small amount of water) is first injected with methanol, cooled to -15~-30°C by the raw gas cooler E1, and then separated by the separator V1 to separate the condensate (The temperature components are mainly methanol, water, and a small amount of dissolved CO, H2, and CO2). The condensate at the bottom of the separator V1 first passes through the feed heater E16, and the temperature rises to 60°C, and then reduces to 0.8MPaG through the pressure reducing valve. After that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com