High-moisture oat hay modulation method for alpine pasturing regions

A preparation method and high-moisture technology, applied in botany equipment and methods, animal husbandry, fruit hanging devices, etc., can solve the problems of lack of oat grass, hay mildew, etc., achieve better color, reduce nutrient loss, and water content less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

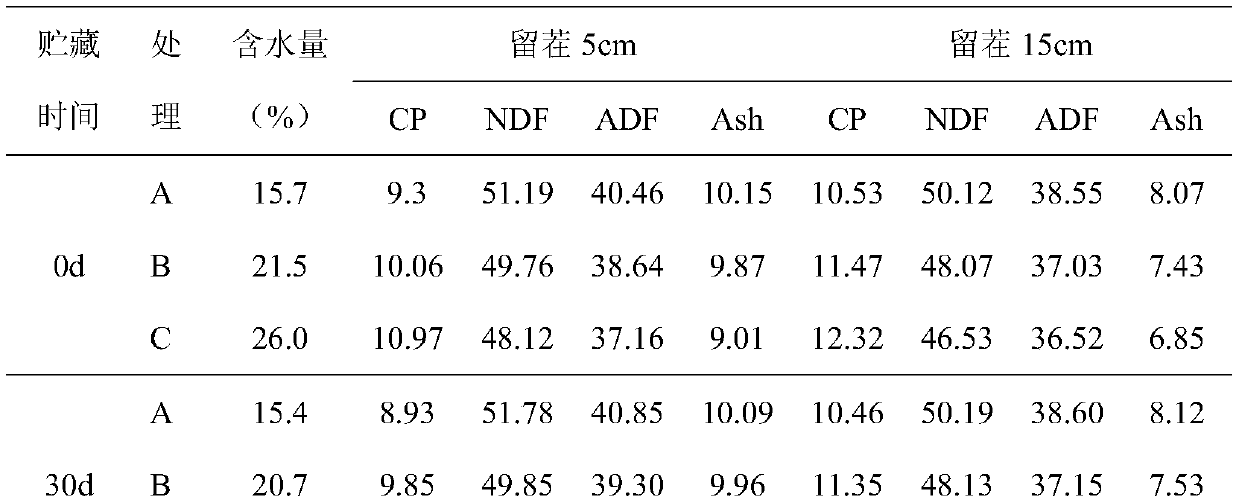

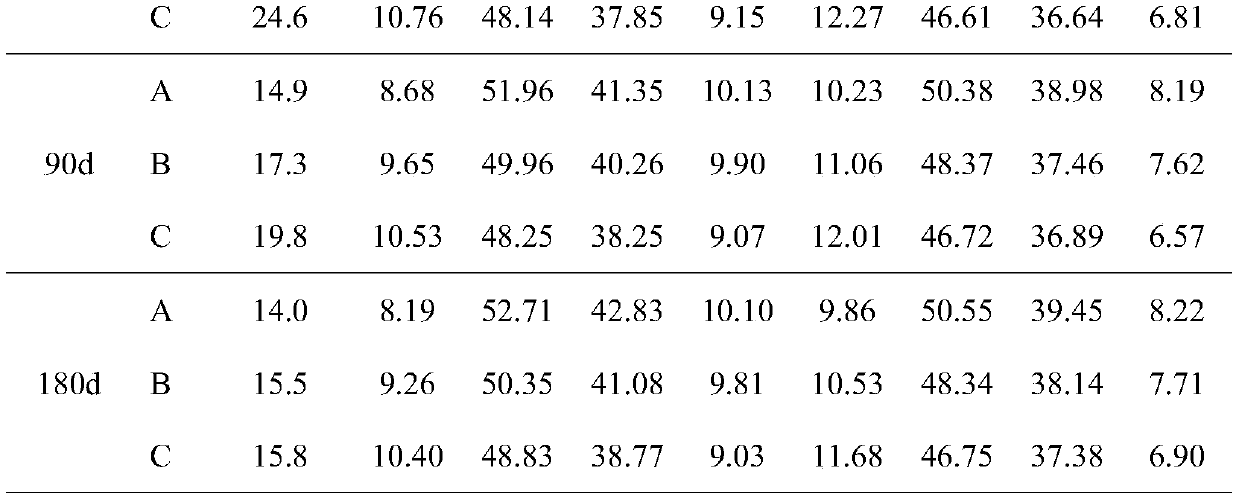

[0017] The field experiment was carried out in Wangertang Township, Xiahe County, Gansu Province, at an altitude of 2380m. Longyan No.3 oats were drilled in April 2017 with a seeder (the seeding rate was 225kg / hm 2 ), no irrigation during the whole growth period, and manual weeding twice. During the flowering period, use a Shanghai Star MDM1700 disc mower to mow stubbles of 5cm and 15cm respectively, and dry them on the spot until the moisture content is 14%-16% (A), 20%-22% (B), and 25% -26% (C) three levels, and then use the New Holland BC5070 small square baler to make 25kg square bales. Transport the bales back to the straw storage shed, and put them in the shape of "pin", leaving a gap of 15cm between the bales. Samples were taken after storage for 0, 30d, 90d, and 180d, respectively, to check the mildew, and to measure the water content, crude protein, neutral detergent fiber, acid detergent fiber, and ash content.

[0018] Table 1 Changes of nutrient components of oa...

Embodiment 2

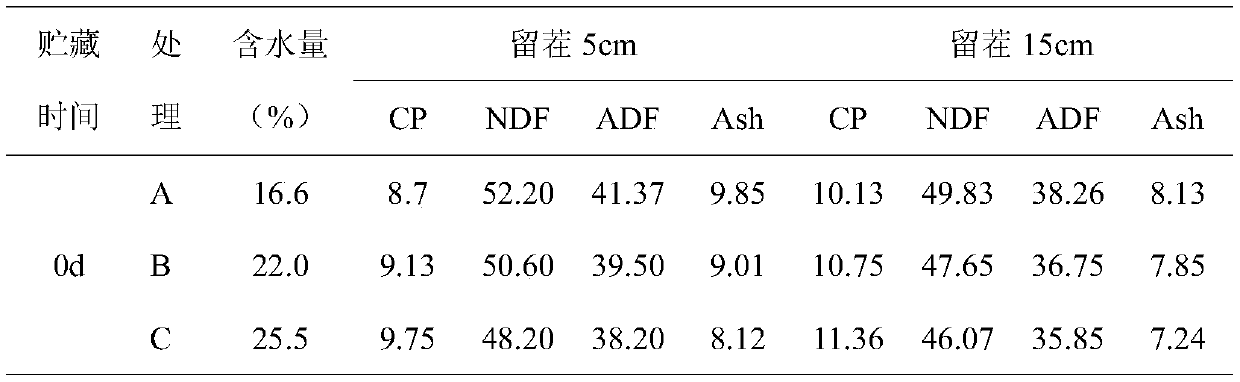

[0023] Field experiments were conducted in Hezuo City, Gannan Prefecture, Gansu Province, at an altitude of 3090m. Baiyan No. 7 oats were drilled with a seeder in late April 2016 (the seeding rate was 225kg / hm 2 ), no irrigation during the whole growth period, and manual weeding once. During the flowering period, use a Shanghai Star MDM1700 disc mower to mow stubble at 5cm and 15cm respectively, and dry it until the water content is 14%-16% (A), 20%-22% (B), 25%-26 %(C) three levels, then use the New Holland BC5070 small square baler to make a 25kg square bundle. Transport the bales back to the straw storage shed, and place them in the shape of "pin", leaving a gap of 20cm between the bales. Samples were taken after storage for 0, 90d, and 180d respectively to check the mildew and determine the water content, crude protein, neutral detergent fiber, acid detergent fiber, and ash content.

[0024] Table 2 Changes of nutrients in oat hay bales with storage time under different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com