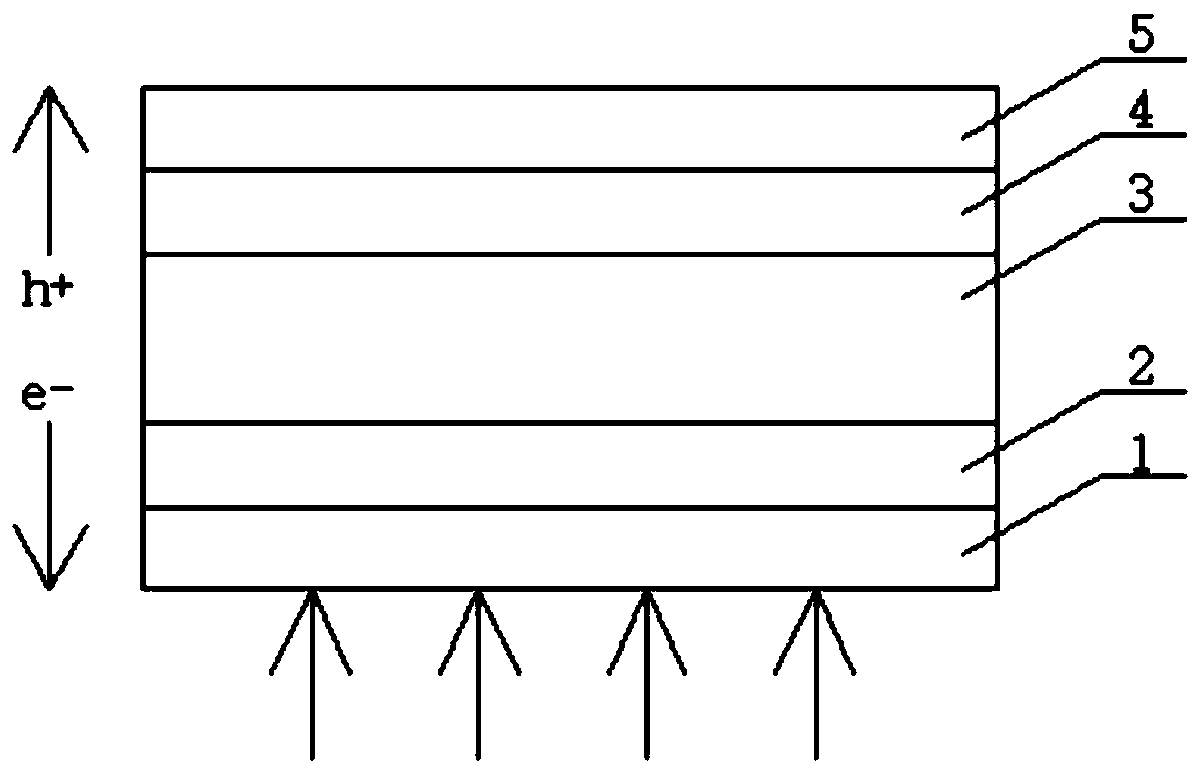

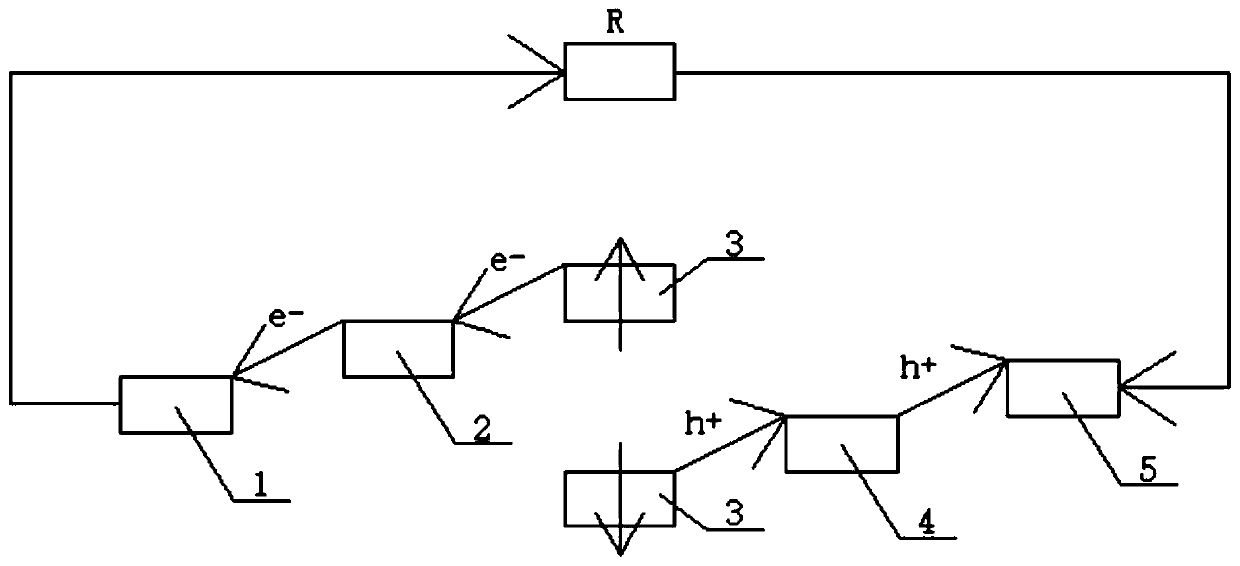

Preparation method of TiO2 electron transport layer for perovskite solar cells

A technology of solar cells and electron transport layers, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of high preparation temperature, difficulty in depositing large-area continuous coatings, and uneven coatings. Achieve the effect of lowering the preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The above TiO 2 The preparation method of electron transport layer comprises the following steps:

[0029] S1. Take 60g of TiO with an average particle size ≤ 100nm 2 , 15g of TiO with an average particle size ≤ 25um 2 ,spare;

[0030] S2. TiO with an average particle diameter≤100nm in step S1 2 Place in 100mL distilled water, ultrasonically disperse evenly;

[0031] S3. Nano-TiO in step S2 2 Add the aqueous solution into the reactor equipped with a stirring device and a heating device. At a stirring rate of 300r / min, first slowly add 5g of sodium tripolyphosphate into the reactor, and after fully dissolving, slowly add the average TiO with a particle size of ≤25um 2 Add it into the reactor, stir at 300r / min for 2h, then evaporate the solvent at a temperature of 110°C and a stirring rate of 180r / min;

[0032] S4. the uniformly dispersed TiO in step S3 2 Particles are slowly added to 25g PDADMAC, and after uniform dispersion, TiO 2 coating;

[0033] S5. first a...

Embodiment 2

[0036] S1. Take 50g of TiO with an average particle size ≤ 100nm 2 , 25g of TiO with an average particle size ≤ 25um 2 ,spare;

[0037] S2. TiO with an average particle diameter≤100nm in step S1 2 Place in 100mL distilled water, ultrasonically disperse evenly;

[0038] S3. Nano-TiO in step S2 2 Add the aqueous solution into the reactor equipped with a stirring device and a heating device. At a stirring rate of 500r / min, first slowly add 8g of sodium tripolyphosphate into the reactor, and after fully dissolving, slowly add the average TiO with a particle size of ≤25um 2 Add it into the reactor, stir at 500r / min for 2h, then evaporate the solvent at a temperature of 120°C and a stirring rate of 240r / min;

[0039] S4. the uniformly dispersed TiO in step S3 2 Particles are slowly added to 25g PDADMAC, and after uniform dispersion, TiO 2 coating;

[0040] S5. first adopt the scraping method to coat the TiO in step S4 2 The paint was coated on the FTO electrode layer of the...

Embodiment 3

[0043] S1. Take 70g of TiO with an average particle size ≤ 100nm 2 , 5g of TiO with average particle size ≤ 25um 2 ,spare;

[0044] S2. TiO with an average particle diameter≤100nm in step S1 2 Place in 100mL distilled water, ultrasonically disperse evenly;

[0045] S3. Nano-TiO in step S2 2 The aqueous solution is added to the reactor equipped with a stirring device and a heating device. At a stirring rate of 600r / min, first slowly add 10g of sodium tripolyphosphate into the reactor, and after fully dissolving, slowly add the average TiO with a particle size of ≤25um 2 Add it into the reactor, stir at 600r / min for 2h, then evaporate the solvent at a temperature of 130°C and a stirring rate of 300r / min;

[0046] S4. the uniformly dispersed TiO in step S3 2 Particles are slowly added to 25g PDADMAC, and after uniform dispersion, TiO 2 coating;

[0047] S5. first adopt the scraping method to coat the TiO in step S4 2 The paint was coated on the FTO electrode layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com