Novel nano water ion generation device

An ion generating device, nano-water technology, which is applied to machines using electrical/magnetic effects, the operation mode of machines, electrical components, etc., can solve the difficulty of increasing assembly or processing, low cooling or heat dissipation efficiency, high voltage voltage drift, etc. To avoid the impact of high voltage voltage drift or discharge current, avoid excessive or insufficient condensate, and maintain stable and constant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

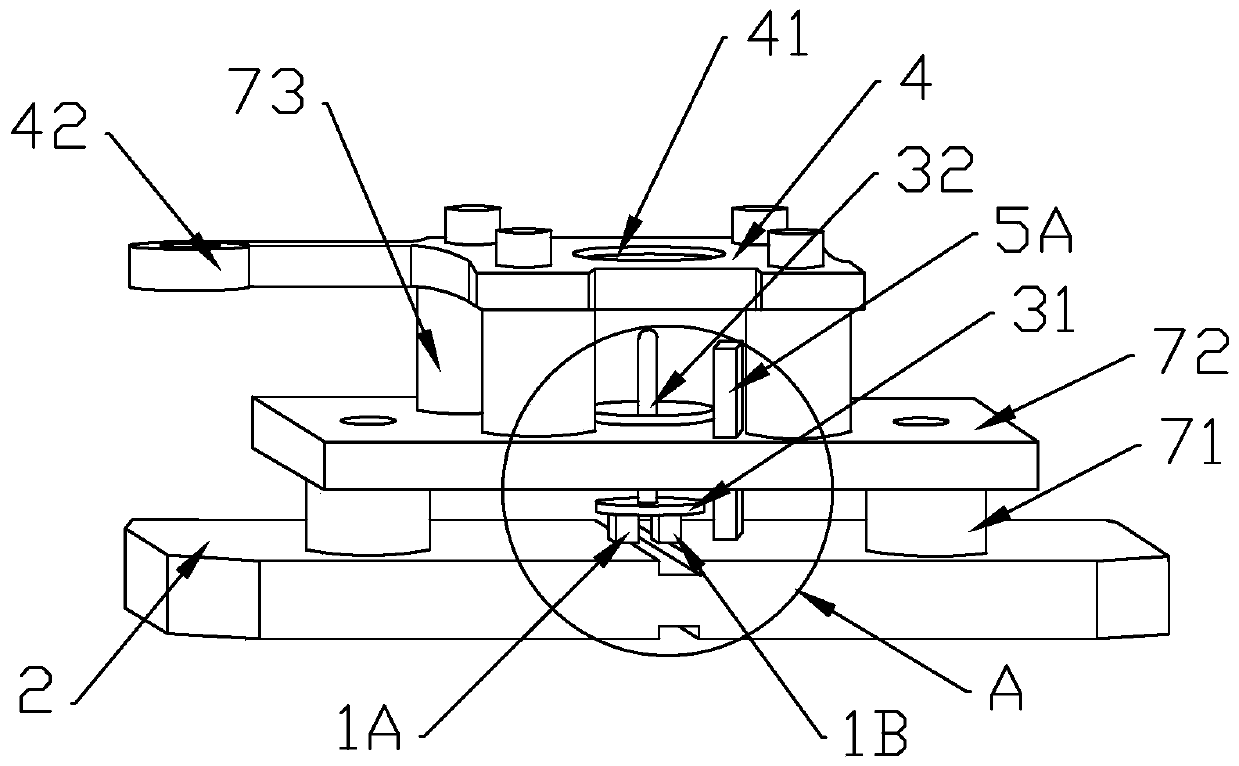

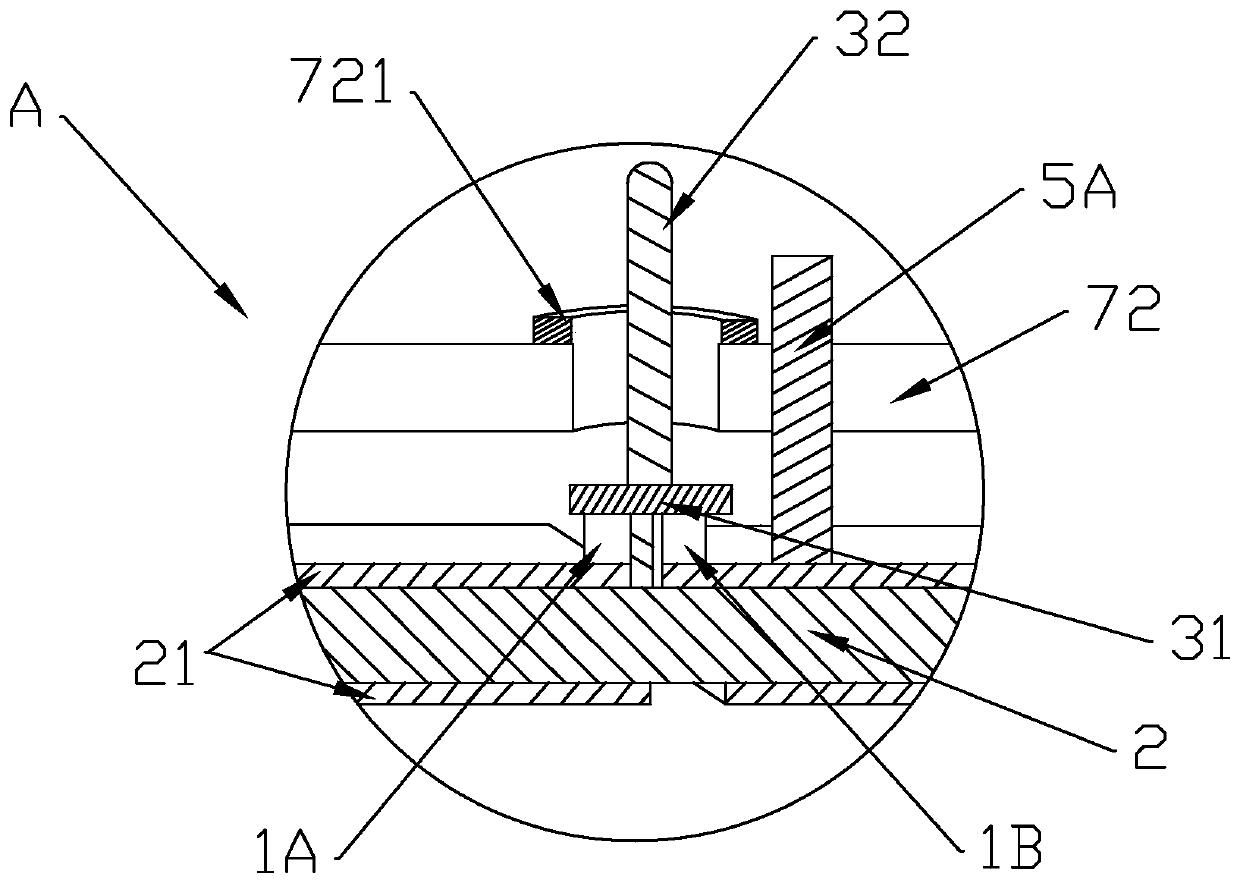

[0035] refer to figure 1 , 2 , the present embodiment provides a novel nanometer water ion generating device, including a pair of semiconductor grains composed of a P-type semiconductor 1A and an N-type semiconductor 1B, one end of the semiconductor grain pair is a cooling end, and the other end is a cooling end. terminal; also includes a water supply electrode and a constant pressure electrode, the water supply electrode includes a water condensation plate 31 and a water supply needle 32, the water condensation plate 31 is arranged below the water supply needle 32, wherein the water condensation plate 31 and the water supply needle 32 The refrigeration ends of the semiconductor crystal grain pair are electrically connected; the constant voltage electrode is arranged on the side of the water supply electrode.

[0036] Specifically, the water supply needle 32 and the condensation pan 31 are integrally formed or the water supply needle 32 is welded and fixed to the center of th...

Embodiment 2

[0056] On the basis of Embodiment 1, in order to accumulate condensed water, realize the self-balancing adjustment of condensed water amount, avoid excessive or insufficient condensed water, so that maintenance and discharge can continue, a water storage component 6 is also set in this embodiment. The water component 6 is arranged on the side of the constant voltage electrode 5A close to the water supply electrode (not shown).

[0057] Specifically, the outer periphery of the water storage component 6 is made of insulating materials, and the inner core is made of water-absorbing or hydrophilic materials, such as sponges and other materials.

Embodiment 3

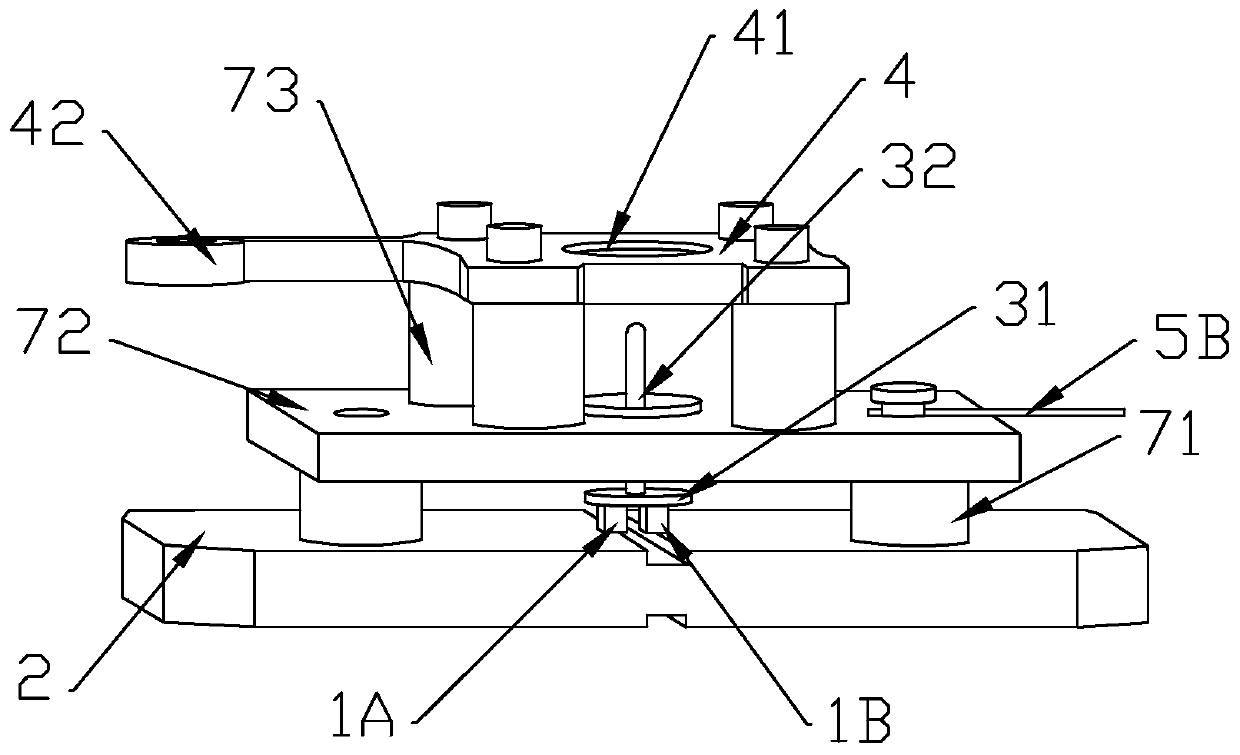

[0059] refer to image 3 , On the basis of Embodiment 1, the constant voltage electrode 5B used in this embodiment is a conductor perpendicular to the water supply electrode, and the end of the constant voltage electrode 5B pointing to the water supply electrode is close to the The semiconductor crystal grain is electrically connected to the conductor cladding layer 21 on one side, and the other end of the constant-voltage electrode 5B is electrically connected to the regulated power supply.

[0060] Specifically, the side of the constant voltage electrode 5B pointing to the water supply electrode is fixed on the support table 72 by screws, and is electrically connected to the conductor coating 21 on the side close to the pair of semiconductor crystal grains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com