Method for measuring surface temperature field based on CdTe film

A surface temperature and measurement method technology, which is applied to thermometers, thermometers, and measuring devices with physical/chemical changes, can solve the problems of unsatisfactory measurement accuracy, difficulty in further improving measurement spatial resolution, and limited layout density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

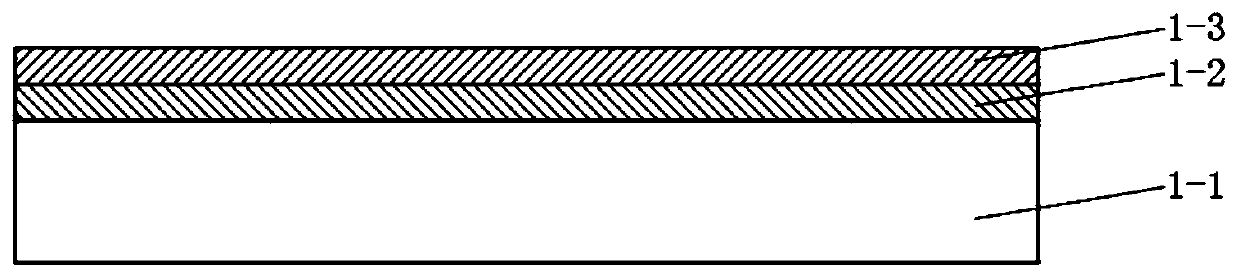

[0024] (1) The structure of the temperature sensor 1 is as follows: image 3 As shown, the specific production process is as follows: First, mix 1g of gelatin (powder) with 6g of aqueous solution and heat to 50°C to form a gelatin solution, then drop 0.3ml of water-soluble CdTe quantum dots into the gelatin solution, shake the mixed solution fully, shake Afterwards, the mixed solution was heated at a constant temperature of 50°C for 15 minutes, and finally the cleaned glass was selected as the glass substrate 1-1, and the mixed solution was uniformly spin-coated on the surface of the glass substrate 1-1 to prepare a CdTe film 1-2, and after cooling for 6-8 hours, the The surface of the CdTe film 1-2 is pasted with a thermally conductive film 1-3.

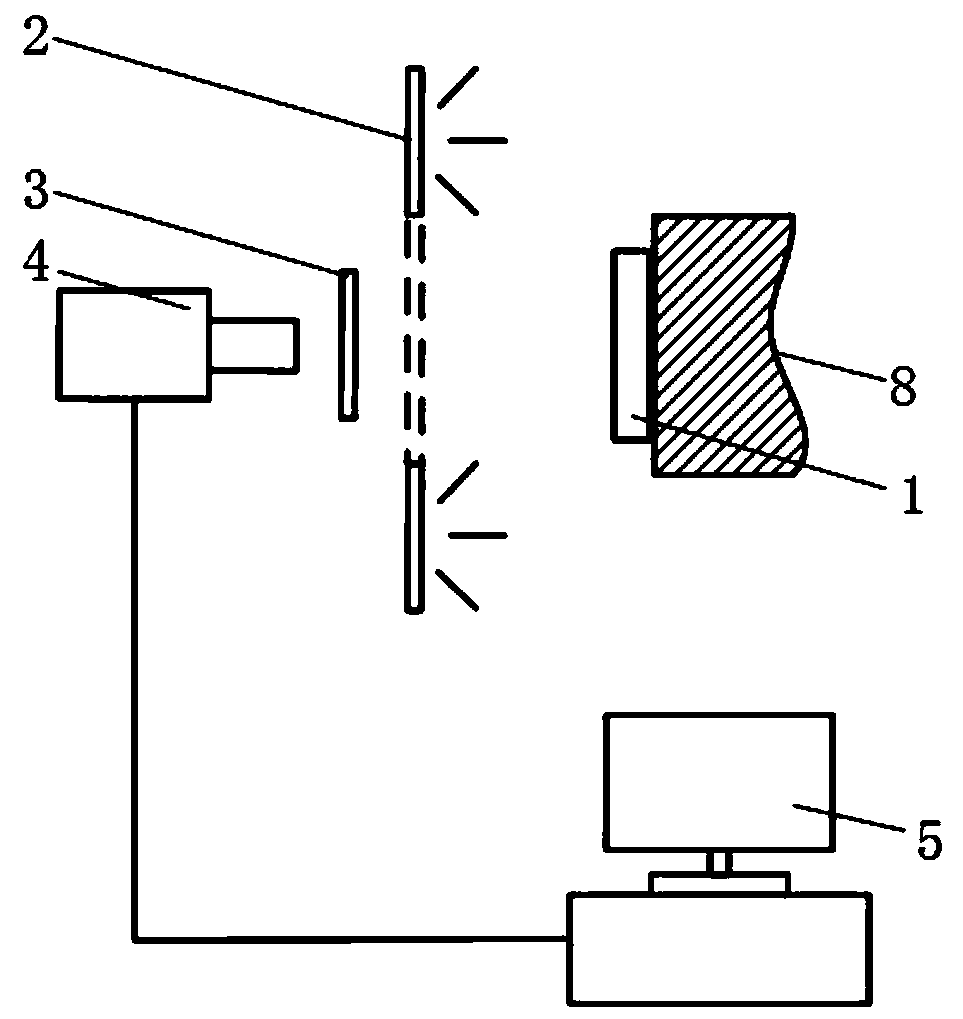

[0025] (2) Temperature calibration system such as figure 1 As shown, a heater 6 is placed above the temperature sensor 1 (the heating surface of the heater 6 is in contact with the heat-conducting film 1-3), the temperature of the ...

Embodiment 2

[0029] (1) The structure of the temperature sensor 1 is as follows: image 3 As shown, the specific production process is as follows: First, mix 2g of gelatin (powder) with 16g of aqueous solution and heat to 70°C to form a gelatin solution, then drop 0.8ml of water-soluble CdTe quantum dots into the gelatin solution, shake the mixed solution fully, shake Afterwards, the mixed solution was heated at a constant temperature of 70°C for 15 minutes, and finally the cleaned glass was selected as the glass substrate 1-1, and the mixed solution was uniformly spin-coated on the surface of the glass substrate 1-1 to prepare a CdTe film 1-2, and after cooling for 6-8 hours, the The surface of the CdTe film 1-2 is pasted with a thermally conductive film 1-3.

[0030] (2) Temperature calibration system such as figure 1 As shown, a heater 6 is placed above the temperature sensor 1 (the heating surface of the heater 6 is in contact with the heat-conducting film 1-3), the temperature of the...

Embodiment 3

[0034] (1) Temperature sensor structure 1 such as image 3 As shown, the specific production process is as follows: First, mix 1g of gelatin (powder) with 10g of aqueous solution and heat it to 90°C to form a gelatin solution, then drop 0.5ml of water-soluble CdTe quantum dots into the gelatin solution, shake the mixed solution fully, shake Afterwards, the mixed solution was heated at a constant temperature of 90°C for 15 minutes, and finally the cleaned glass was selected as the glass substrate 1-1, and the mixed solution was evenly spin-coated on the surface of the glass substrate 1-1 to prepare a CdTe film 1-2, which was cooled for 6-8 hours and then placed on the The surface of the CdTe film 1-2 is pasted with a thermally conductive film 1-3.

[0035] (2) Temperature calibration system such as figure 1 As shown, a heater 6 is placed above the temperature sensor 1 (the heating surface of the heater 6 is in contact with the heat-conducting film 1-3), the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com