Low-temperature phase-change energy-storage electric heater

A low-temperature phase change, electric heating technology, applied in electric heating systems, household heating, space heating and ventilation details, etc., can solve the problem of low thermal conductivity of paraffin wax, and achieve less potential safety hazards, more energy storage, and energy storage density. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

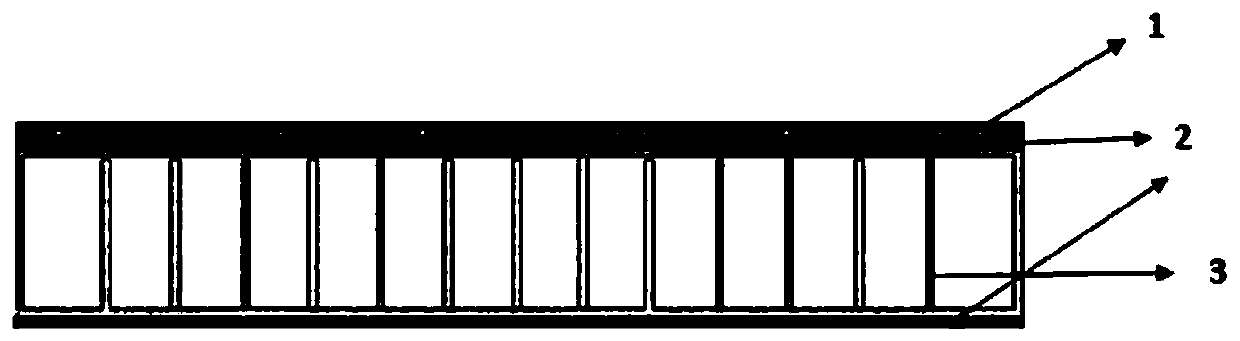

[0022] like Figure 1-2 , an embodiment of the present invention provides a low-temperature phase change energy storage electric heater, including:

[0023] A phase change material container filled with paraffin wax.

[0024] The heating plate 2 is located outside the phase change material container, connected to an external power supply, and is used for heating the paraffin in the phase change material container.

[0025] The thermal insulation layer 1 is located on the outer side of the heating plate 2 and is only installed on the rear side for thermal insulation and safety protection.

[0026] The outer frame is located around the thermal insulation layer 1, the heating plate 2 and the phase change material container, and plays a supporting role.

[0027] The temperature controller is located on the outer frame and is used to connect the power supply and the heating plate to control the heating of the heating plate.

Embodiment 2

[0029] In this embodiment, the paraffin wax is selected from 64# refined paraffin wax. The remaining technical solutions in this embodiment are consistent with those in Embodiment 1, and at the same time, the technical solutions adopted in this embodiment are also applicable to other embodiments.

[0030] In the embodiment of the present invention, organic phase change materials are used as energy storage materials, and the liquid-solid phase transition and specific heat capacity of phase change materials are used to store and release heat energy. Mixed alkanes with a melting point range of 50-70°C and a latent heat of melting of 200kJ / kg can be selected. class or alkanoic acid.

Embodiment 3

[0032] In this embodiment, the phase change material includes at least one of the following materials:

[0033] Paraffin, palmitic acid, myristic acid and stearic acid.

[0034] The remaining technical solutions in this embodiment are consistent with those in Embodiment 1, and at the same time, the technical solutions adopted in this embodiment are also applicable to other embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Latent heat of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com