Internal combustion engine thermal exhaust treatment device

A treatment device and hot tail gas technology, applied in the direction of exhaust devices, noise reduction devices, mechanical equipment, etc., can solve the problems of high cost of tail gas treatment, secondary pollution, unfavorable energy saving and environmental protection, etc., and achieve simple structure, fast purification speed, and energy saving The effect of vehicle usage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

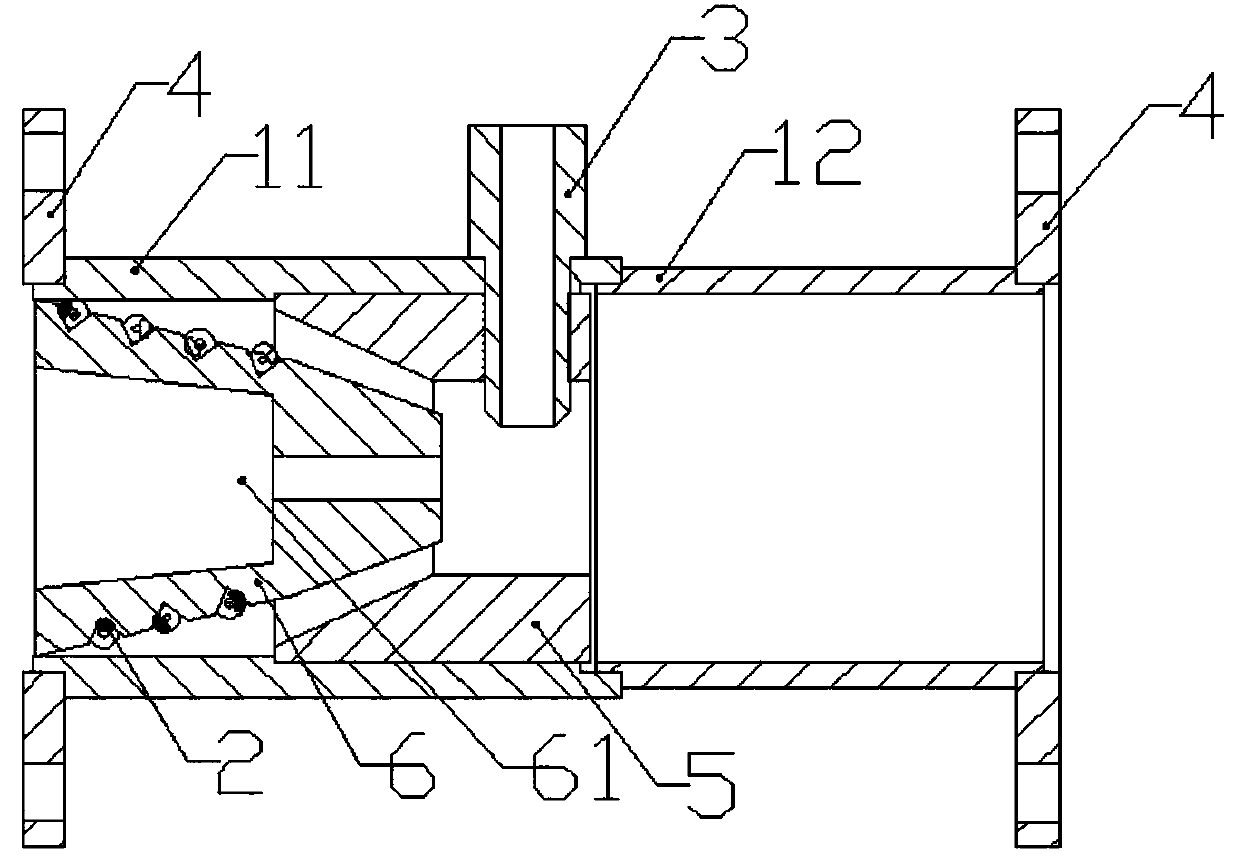

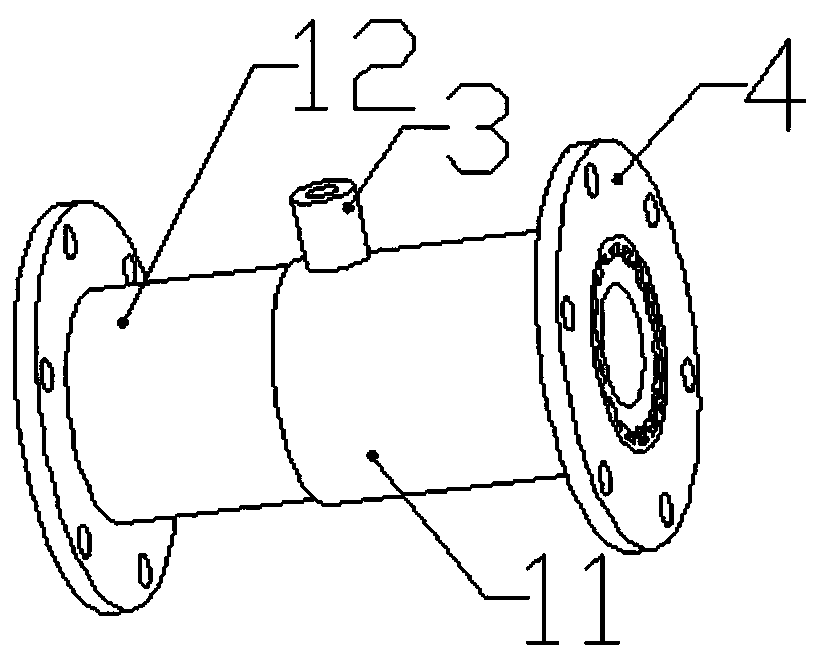

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

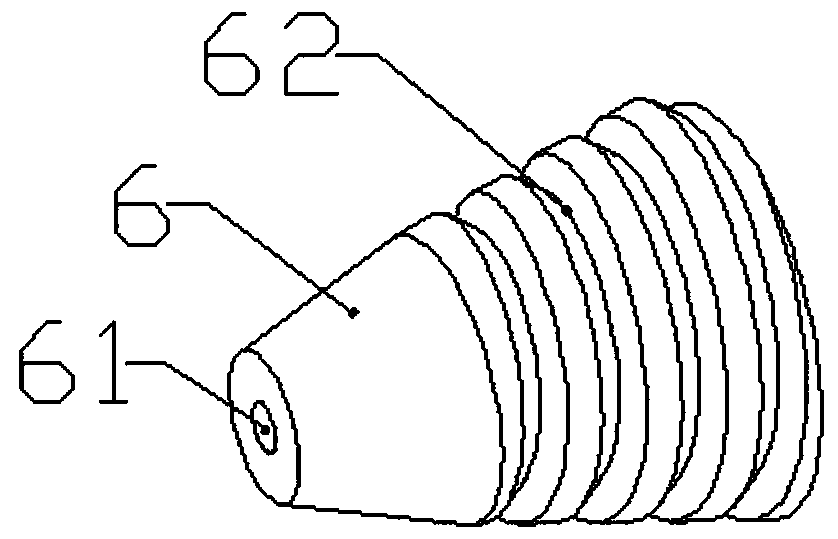

[0023] Such as Figure 1 to Figure 6 As shown, a kind of internal combustion engine hot tail gas treatment device of the present invention comprises a pipe body 1 and a heating belt 2, the pipe body 1 is a Venturi tube structure, an opening 13 is arranged on the outer wall of the small end of the pipe body 1, and the heating belt 2 is wound On the outer wall of the large end of the pipe body 1. It should be understood by those skilled in the art that the preferred tube body 1 of this device is a Venturi tube structure, that is, a Venturi tube, so that the tube body 1 is a variable diameter structure, and an opening 13 is provided on the side wall of the small end of the tube body 1 , while the heating tape 2 is directly wound on the pipe body 1 . In actual use, the two ends of the pipe body 1 are directly connected to the automobile muffler and the exhaust pipe, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com