Ultradeep underground continuous trenching construction method

A technology for trough construction and deep ground, applied in sheet pile wall, foundation structure engineering, earth mover/shovel, etc., can solve the problems of inability to carry out construction, and it is difficult to place steel cages in place, so as to shorten the construction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiments.

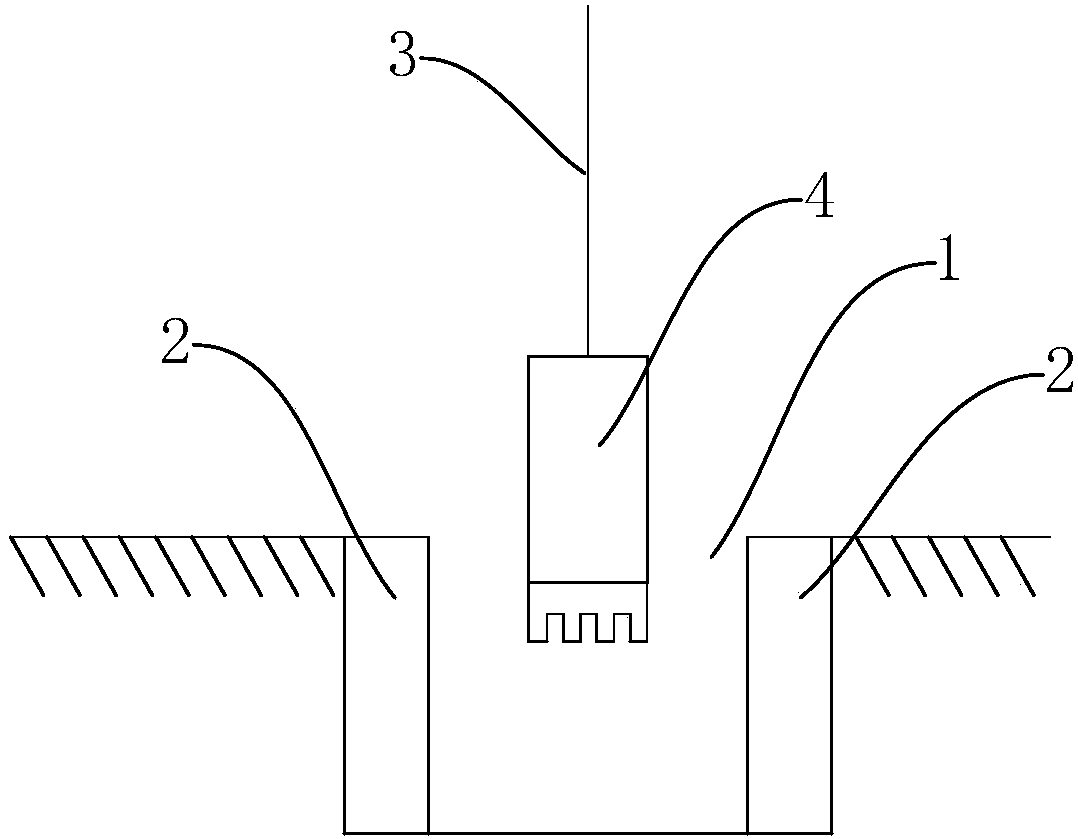

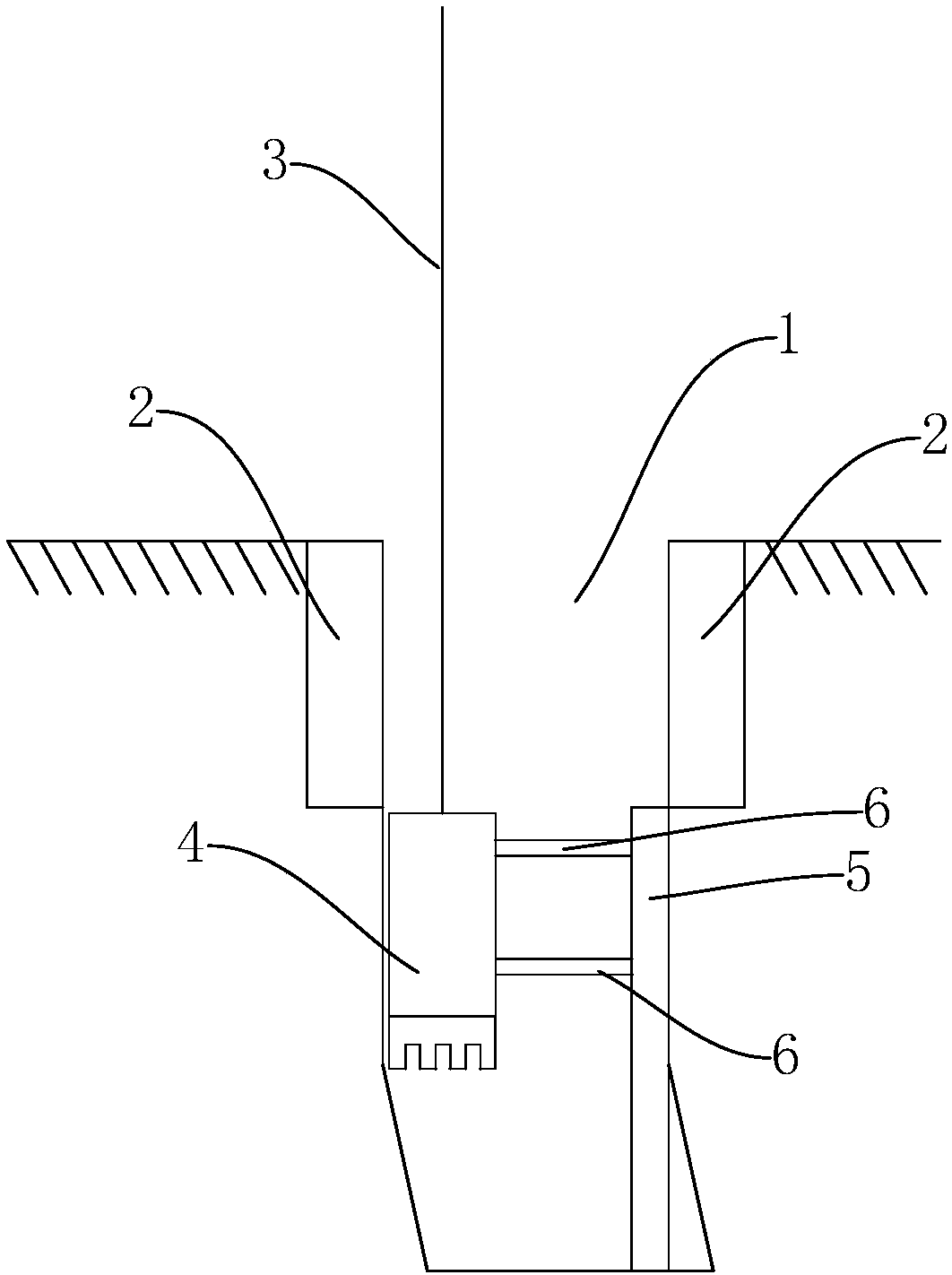

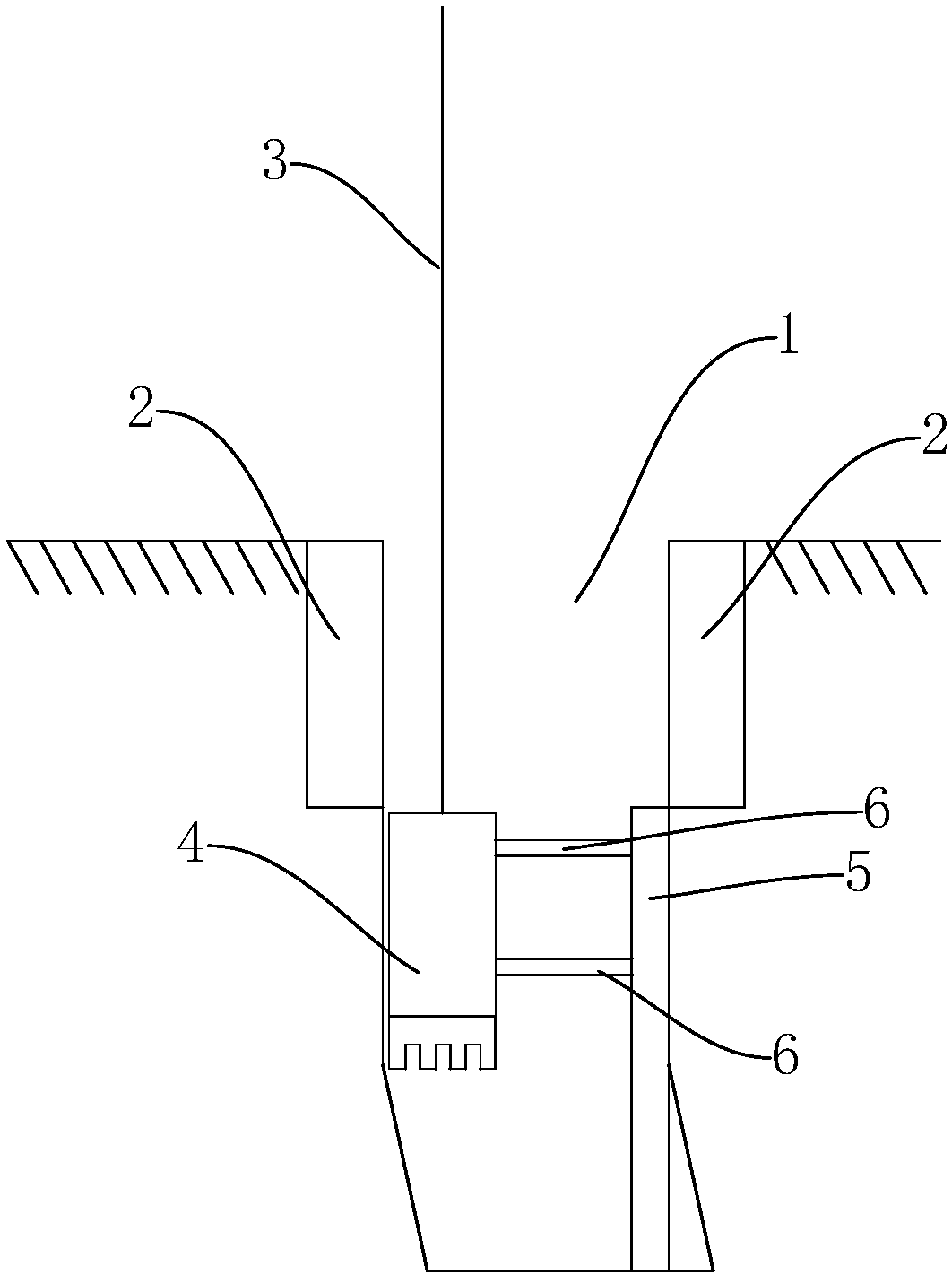

[0015] The construction method of forming a trench for the ultra-deep underground continuous wall uses a hydraulic grab bucket to excavate the trench. Such as figure 1 As shown, before excavation, two sections of guide walls 2 are first set up according to the width of the groove 1, and the distance between the two sections of guide walls 2 is the same as the width of the groove 1. The guide wall 2 extends 1-1.5 meters deep from the ground to the ground. The hydraulic grab 4 is hung by the wire rope 3 so that the hydraulic grab 4 is digging between the two sections of guide walls 2. In the process of forming the groove, when the groove depth is less than 10 meters, the distance between the two sections of the guide wall 2 and the steel wire 3 is measured by the stop gauge. If the distance between the wire rope 3 and the two sections of guide walls 2 meets the measurement requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com