Three-phase foam channel-sealing agent, preparation method thereof, and thickened oil exploiting and plugging method

A channel sealing agent and foam technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of long-term stable use, poor high temperature resistance, etc., and achieve high-efficiency plugging depth profile control and good stability , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

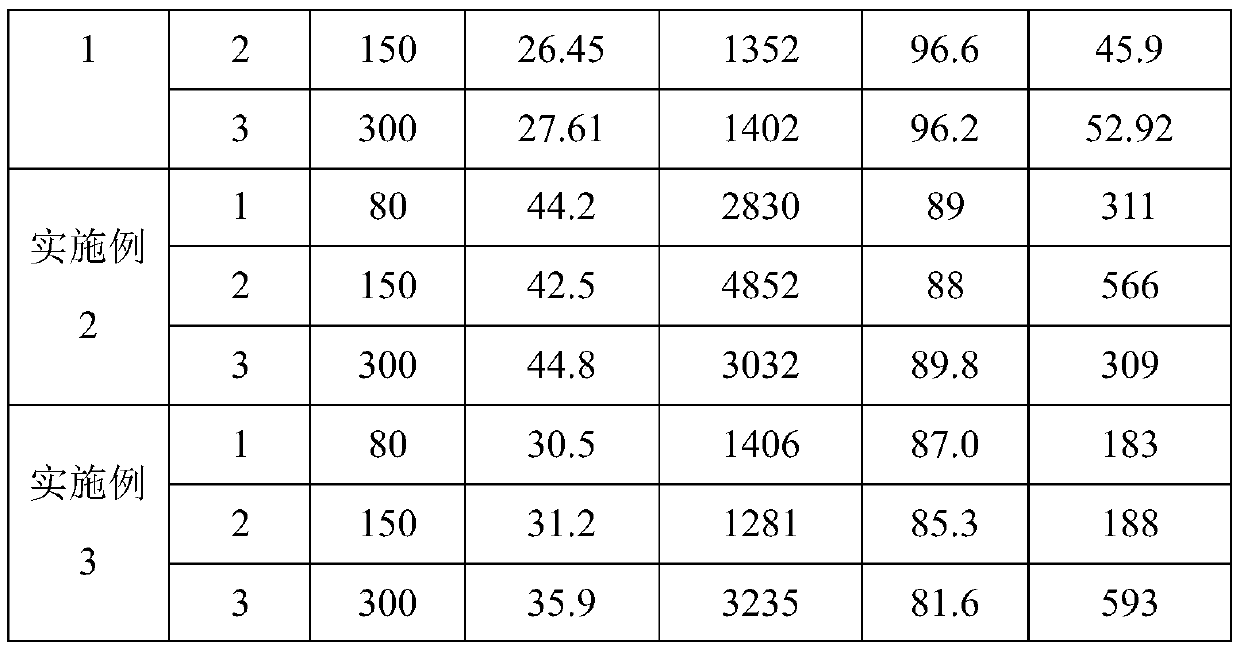

Embodiment 1

[0028] The three-phase foam blocking agent of this embodiment is composed of the following components in weight percent: 0.3% sodium lauryl sulfate, 3% α-starch, 3% acrylamide, 0.02% potassium persulfate, N,N- 0.1% methylene bisacrylamide, 0.2% sodium sulfite, 0.5% solid phase particles, and the balance is water.

[0029] The solid-phase particles are a mixture of fly ash, Portland cement and resin-coated particles, and the mass ratio of fly ash, Portland cement and resin-coated particles is 1:4:1.25.

[0030] The preparation method of the three-phase foam blocking agent of the present embodiment comprises the following steps:

[0031] 1) Mix the α-starch, acrylamide, potassium persulfate, N,N-methylene bisacrylamide, sodium sulfite and 1 / 2 of the total water, stir until gelatinization is complete, and stand at 80°C for 40 minutes to obtain Starch gel system; dissolving the sodium lauryl sulfate in the formula amount in the remaining water, and then adding solid phase granule...

Embodiment 2

[0035] The three-phase foam blocking agent of this embodiment is composed of the following components in weight percent: 0.3% sodium lauryl sulfate, 3.5% α-starch, 4% acrylamide, 0.01% potassium persulfate, N,N- 0.15% methylene bisacrylamide, 0.1% sodium sulfite, 15% solid particles, and the balance is water.

[0036] The solid-phase particles are a mixture of fly ash, Portland cement and resin-coated particles, and the mass ratio of fly ash, Portland cement and resin-coated particles is 1:4:3.

[0037] The preparation method of the three-phase foam blocking agent of the present embodiment comprises the following steps:

[0038] 1) Mix α-starch, acrylamide, potassium persulfate, N,N-methylene bisacrylamide, sodium sulfite and 4 / 5 of the total water, stir until gelatinization is complete, and stand at 80°C for 30 minutes to obtain Starch gel system; dissolving the sodium lauryl sulfate in the formula amount in the remaining water, and then adding solid phase granules to obtain...

Embodiment 3

[0042] The three-phase foam blocking agent of this embodiment is composed of the following components in percentage by weight: sodium lauryl sulfate 0.3%, α-starch 4%, acrylamide 3.5%, potassium persulfate 0.015%, N,N- 0.12% methylene bisacrylamide, 0.15% sodium sulfite, 30% solid particles, and the balance is water.

[0043] The solid-phase particles are a mixture of fly ash, Portland cement and resin-coated particles, and the mass ratio of fly ash, Portland cement and resin-coated particles is 1:4:5.

[0044] The preparation method of the three-phase foam blocking agent of the present embodiment comprises the following steps:

[0045] 1) Mix α-starch, acrylamide, potassium persulfate, N,N-methylene bisacrylamide, sodium sulfite and 3 / 5 of the total water, stir until gelatinization is complete, and stand at 80°C for 60 minutes to obtain Starch gel system; dissolving the sodium lauryl sulfate in the formula amount in the remaining water, and then adding solid phase granules to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com