Polyolefin film for backboard of photovoltaic cell and preparation method thereof

A photovoltaic cell and polyolefin film technology, applied in photovoltaic power generation, chemical instruments and methods, applications, etc., can solve problems such as additive precipitation, achieve the effects of improving color spots, improving compatibility, and ensuring long-term performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

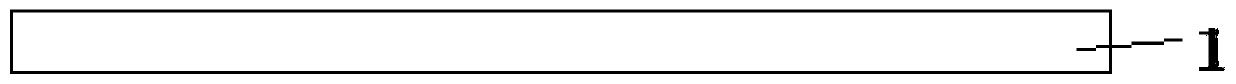

[0067] The polyolefin film for the photovoltaic cell backboard of the present embodiment is a single-layer structure, which is the side connecting layer 1 of the EVA adhesive film. In parts by mass, the side connecting layer 1 of the EVA adhesive film comprises the following components: 25 parts of polypropylene, polyethylene 55 parts, 5 parts of polypropylene grafted maleic anhydride, 15 parts of titanium dioxide, 0.8 parts of light stabilizer, 0.5 parts of antioxidant, and the thickness is 200 μm.

[0068] Among them, the light stabilizer is bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, the antioxidant is 0.3 parts of phenolic antioxidant, 0.2 part of phosphite antioxidant Oxygen mixture.

[0069] The preparation method of the polyolefin film for the photovoltaic cell backboard of this embodiment includes the following steps: firstly, uniformly mix each raw material resin and auxiliary agent in a high-speed mixer, and then granulate through a twin-screw extruder, and the ...

Embodiment 2

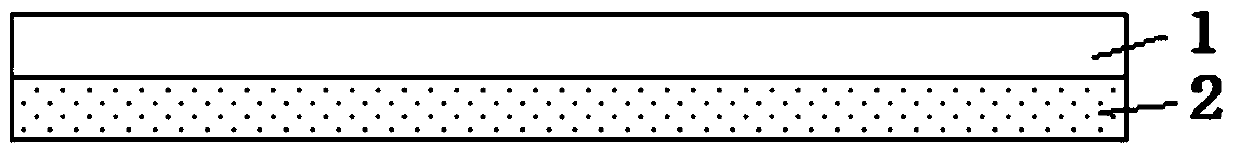

[0072] The polyolefin film for the photovoltaic cell backboard of this embodiment has a two-layer structure, including an EVA adhesive film side connection layer 1 and a water blocking layer 2, wherein,

[0073] In terms of parts by mass, the side connection layer 1 of the EVA film contains the following components: 25 parts of polypropylene, 55 parts of polyethylene, 5 parts of polypropylene grafted maleic anhydride, 15 parts of titanium dioxide, 0.8 parts of light stabilizer, antioxidant 0.5 part of agent, and its thickness is 40 μm. Among them, the light stabilizer is bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, the antioxidant is 0.3 parts of phenolic antioxidant, 0.2 part of phosphite antioxidant Oxygen mixture.

[0074] In parts by mass, the water blocking layer 2 contains the following components: 35 parts of polypropylene, 65 parts of polyethylene, 0.2 part of light stabilizer, 0.5 part of antioxidant, and its thickness is 160 μm. Among them, the light stabilizer...

Embodiment 3

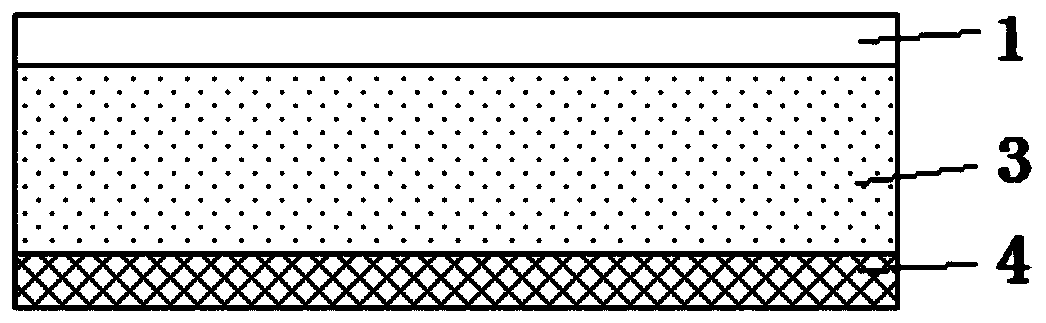

[0078] The polyolefin film for the photovoltaic cell backboard of this embodiment has a three-layer structure, including an EVA adhesive film side connection layer 1, a skeleton layer 3 and an air side weatherproof layer 4, wherein,

[0079] In terms of parts by mass, the side connection layer 1 of the EVA film contains the following components: 25 parts of polypropylene, 55 parts of polyethylene, 5 parts of polypropylene grafted maleic anhydride, 15 parts of titanium dioxide, 0.8 parts of light stabilizer, antioxidant 0.5 parts of agent, the thickness is 40μm. Among them, the light stabilizer is bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, the antioxidant is 0.3 parts of phenolic antioxidant, 0.2 part of phosphite antioxidant Oxygen mixture.

[0080] In parts by mass, the skeleton layer 3 contains the following components: 75 parts of polypropylene, 10 parts of polyethylene, 15 parts of POE, 0.2 parts of light stabilizer, 0.5 parts of antioxidant, and the thickness is 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com