a rewinding machine

A technology of rewinding machine and machine body, which is applied in the field of rewinding machines, can solve problems such as work efficiency impact and long downtime, and achieve the effects of improving work efficiency, avoiding free movement, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

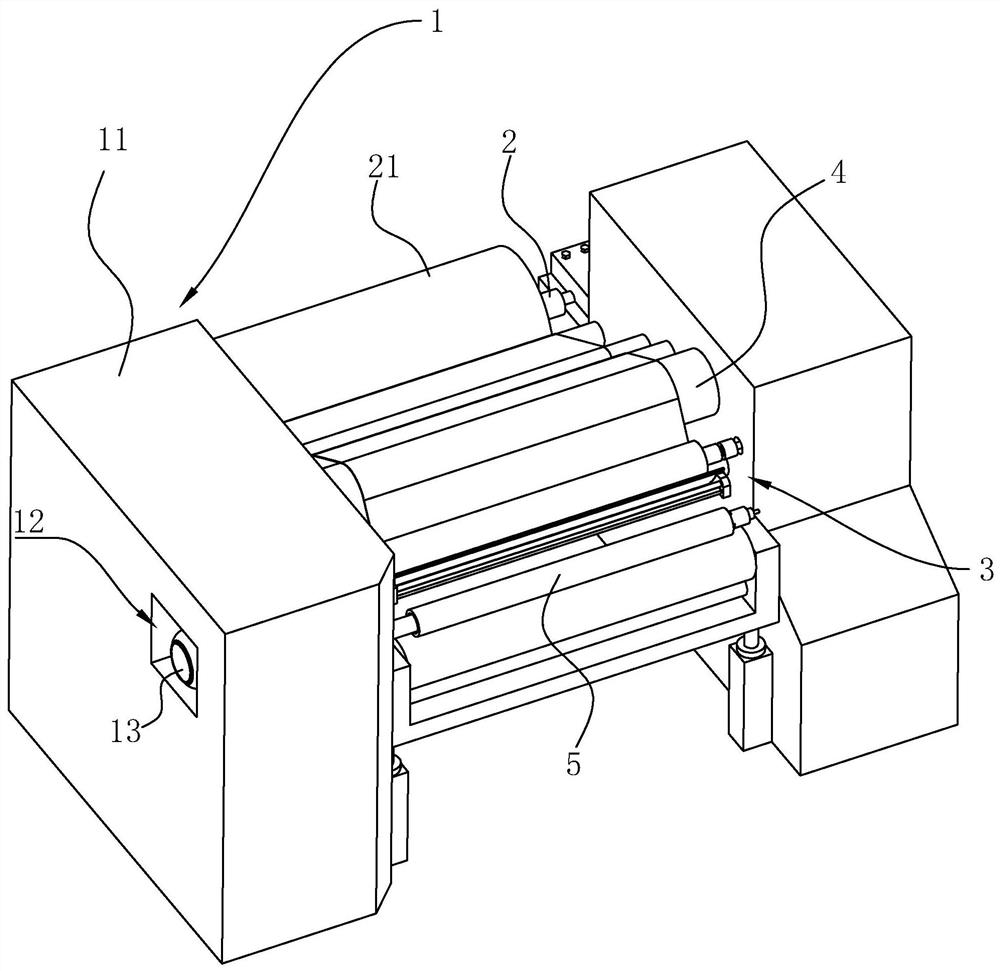

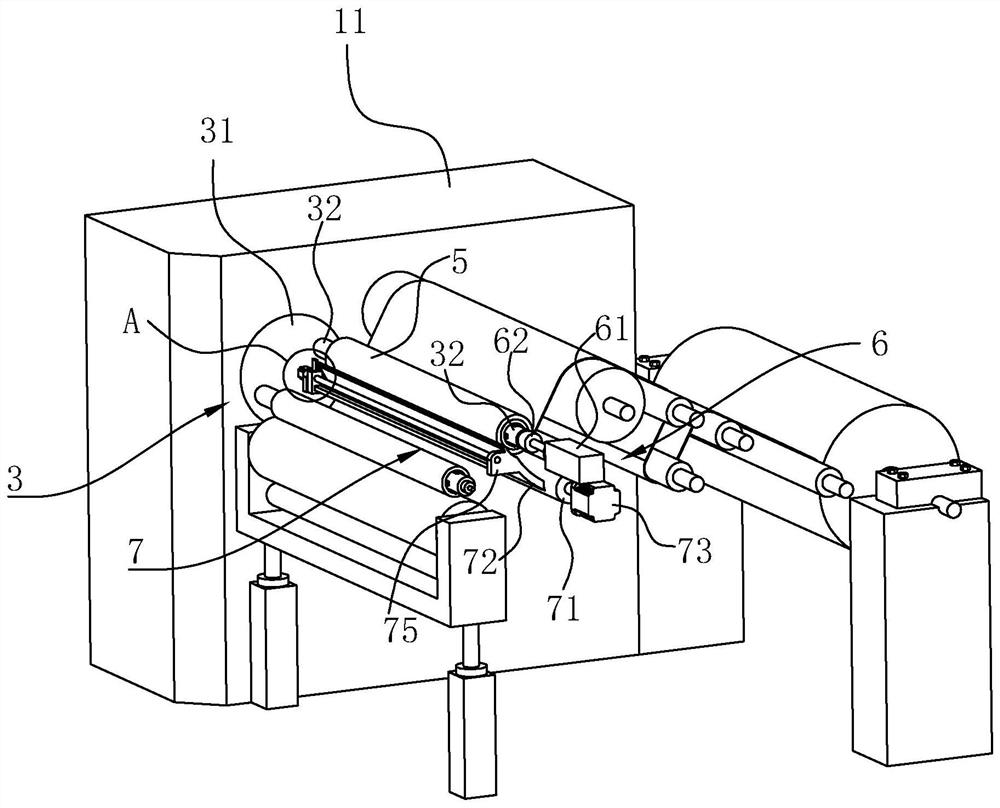

[0040] Embodiment: a kind of rewinding machine, as figure 1 As shown, it includes a body 1 and a feeding roller 2 and a winding assembly 3 arranged on the body 1; the body 1 includes two symmetrically arranged support seats 11; the feeding roller 2 and the winding assembly 3 are respectively installed on two supports The middle of the seat 11 is located at both ends of the machine body 1; a plurality of transition rollers 4 with different heights are arranged between the feeding roller 2 and the winding assembly 3; a material roll 21 is installed on the feeding roll 2, and the material roll 21 The paper passes through a plurality of transition rollers 4, the transition rollers 4 can stretch the paper, so that the paper can be tensioned, and then the end of the paper stretches into the winding assembly 3, and the winding assembly 3 can be equipped with a winding drum 5 , the paper can be rewound on the winding reel 5, so as to achieve the purpose of dividing the paper.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com