Moped for mounting of steel bracing wires and use method of moped

A moped and pull bar technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of large labor costs for reverse transportation machinery, cumbersome moving springboards, and increased construction costs, saving labor and reducing the weight of the frame. , the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

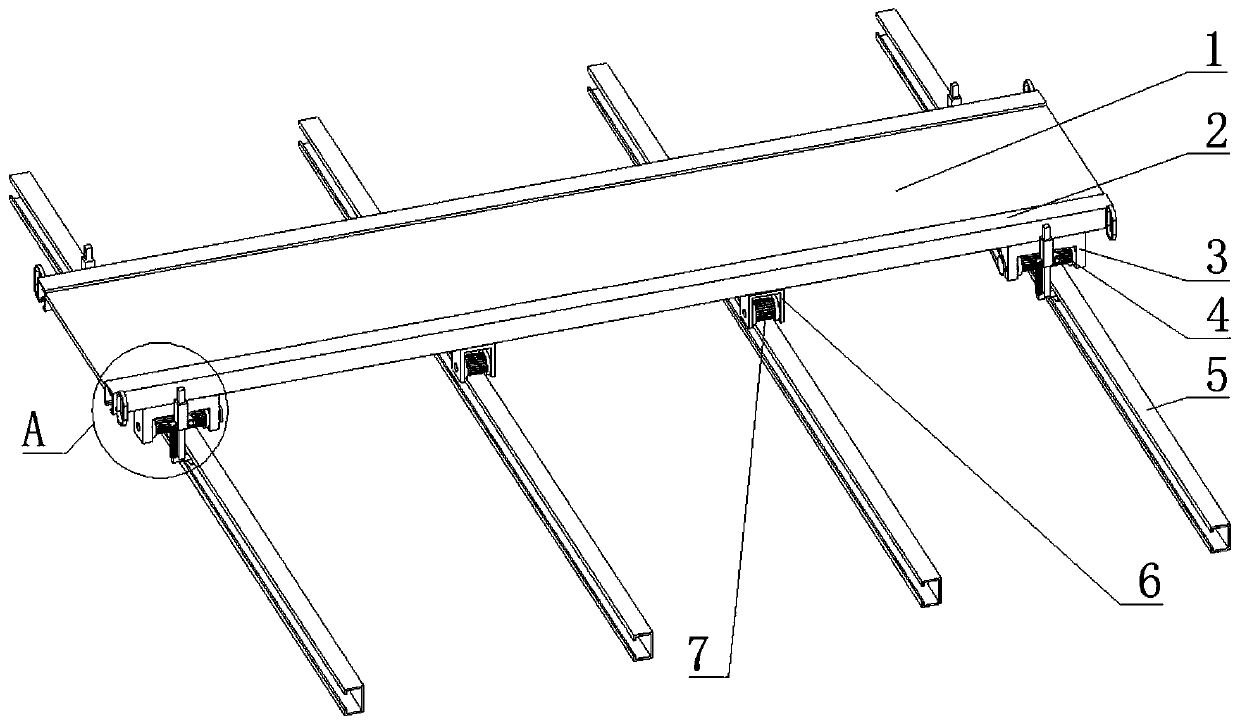

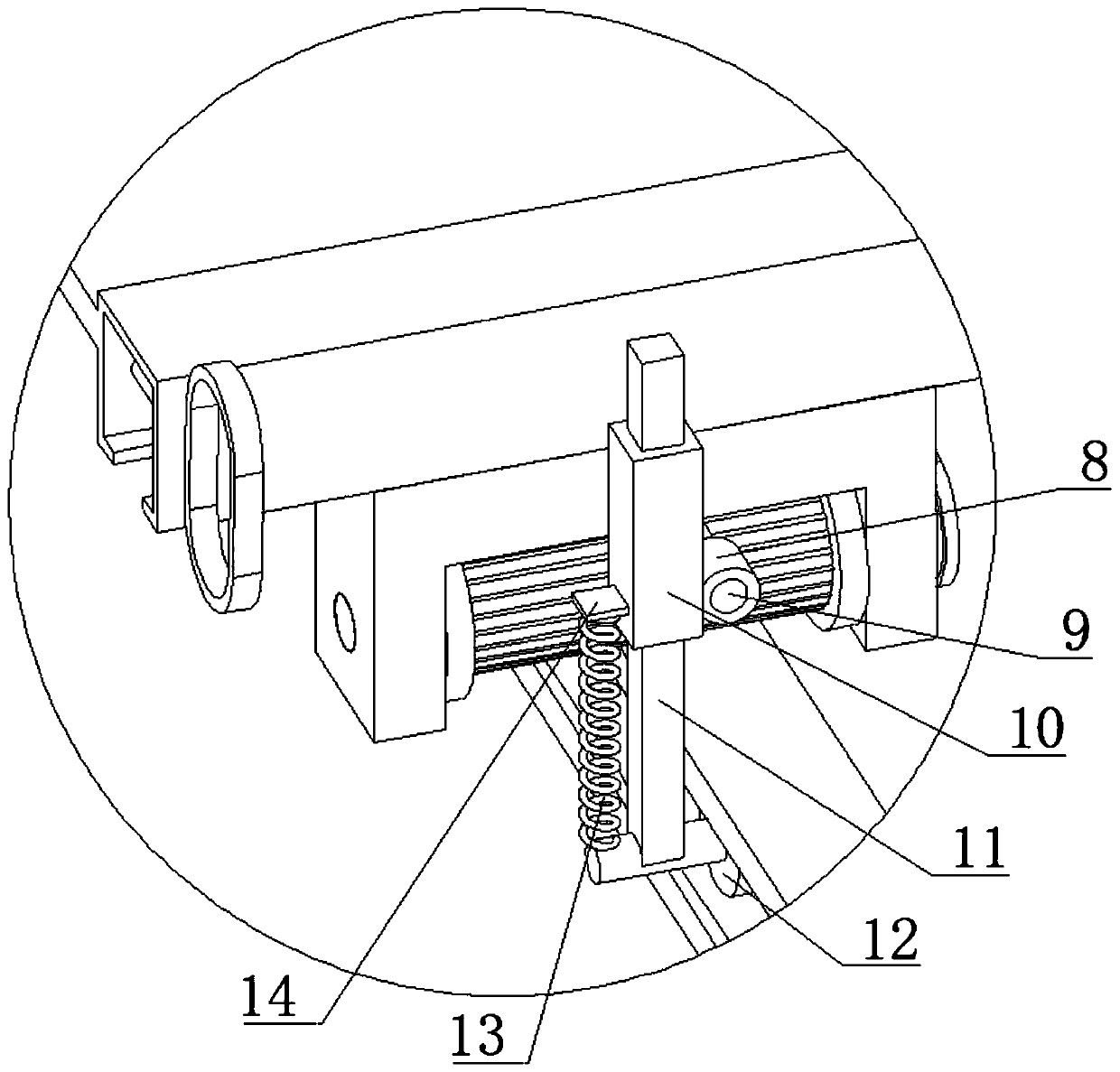

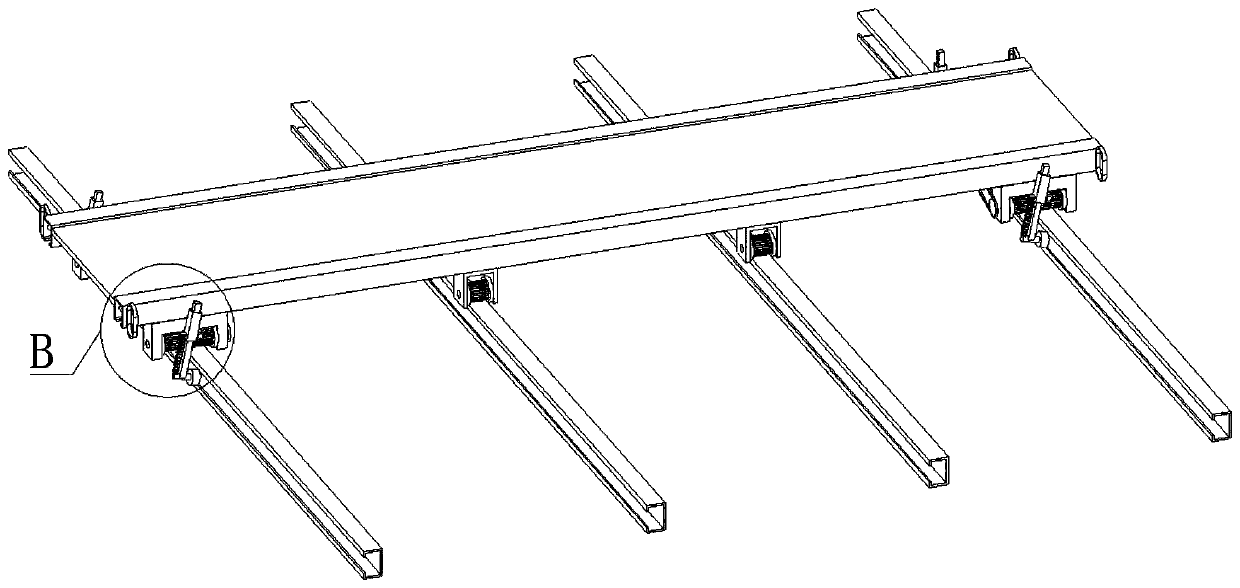

[0037] Such as Figure 1-Figure 14 As shown, the present invention includes a support module, a group of auxiliary support modules is provided in the middle part of the lower side of the support module, power modules are respectively provided at both ends of the lower side of the support module, and locks are respectively provided at both ends of the two power modules. Tight module one.

[0038] The support module includes a support plate 1, the two sides of the support plate 1 are respectively fixedly connected with U-shaped rails 2 with flanging, and the two ends of the U-shaped rails 2 are respectively threaded to limit screw rods 28, each The outer ends of the limiting screws 28 are respectively fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com