Horizontal rotating mold clamping mechanism of injection molding machine

A technology of horizontal rotation and mold clamping mechanism, which is applied in the field of injection molding machines, can solve the problems of prolonged dry cycle of injection molding, increase of dry cycle of molding machines, high assembly requirements, etc., and achieve the effect of shortening the injection molding cycle, reducing the injection molding cycle and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

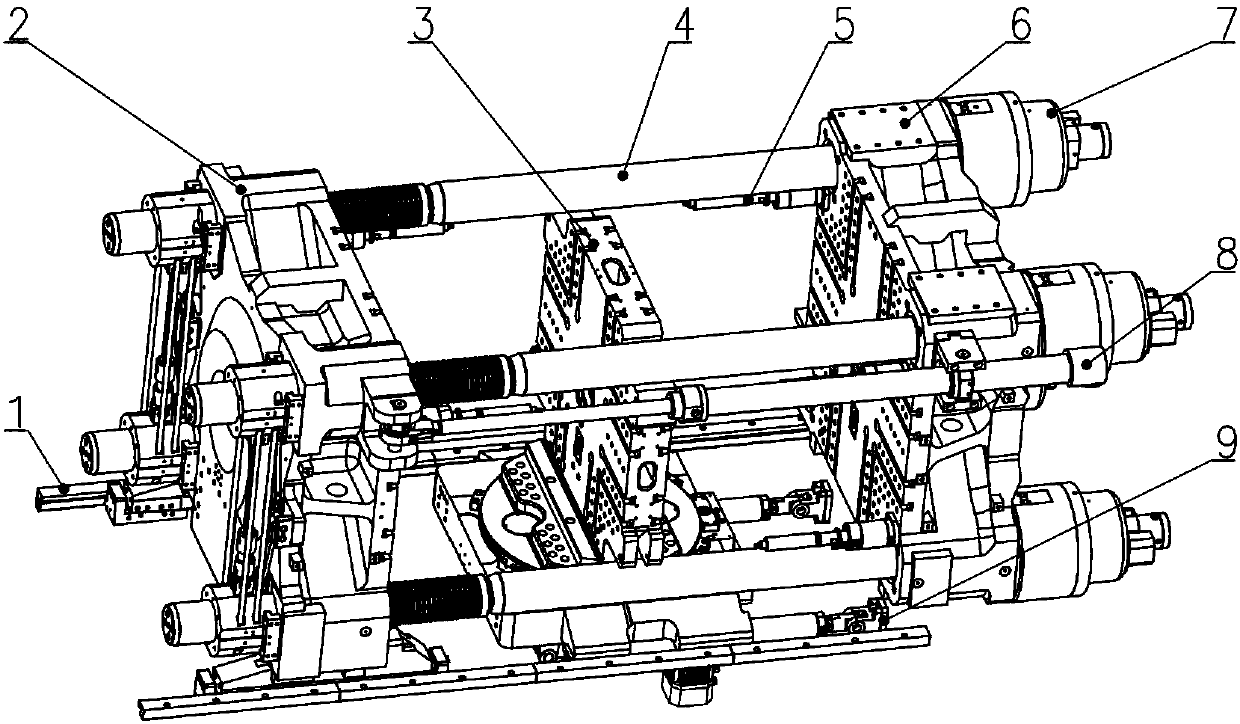

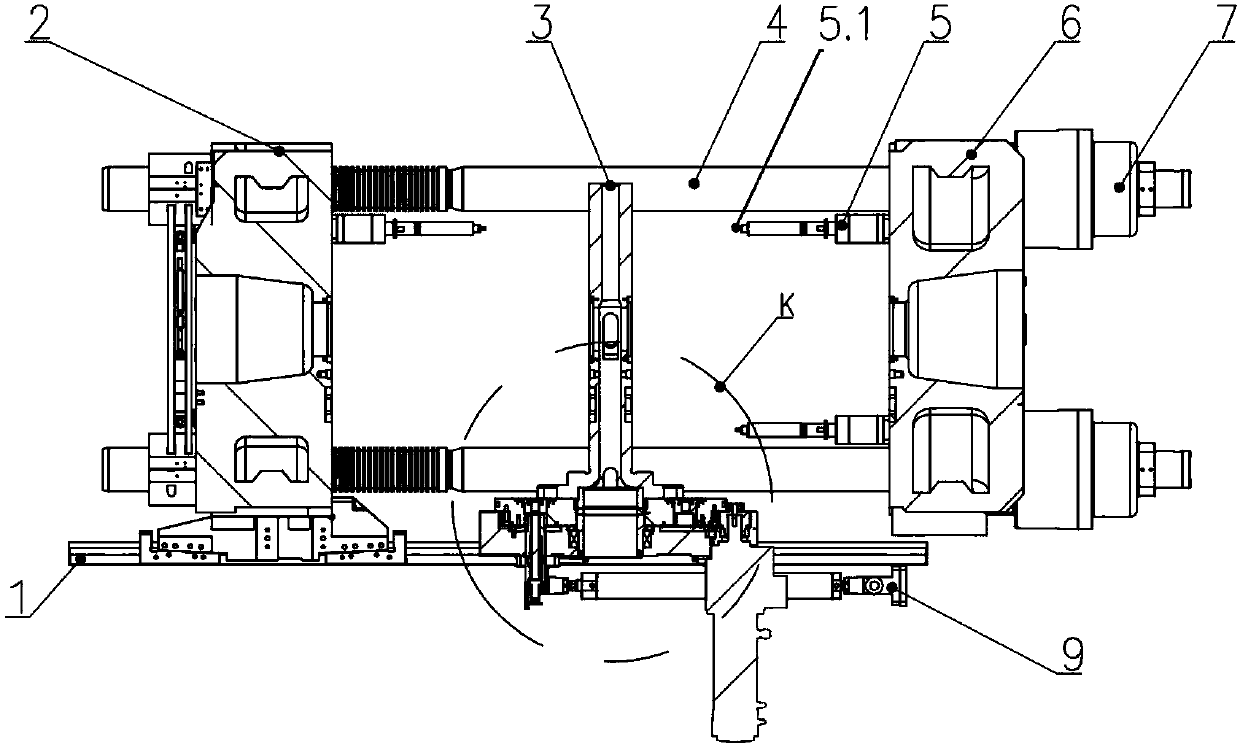

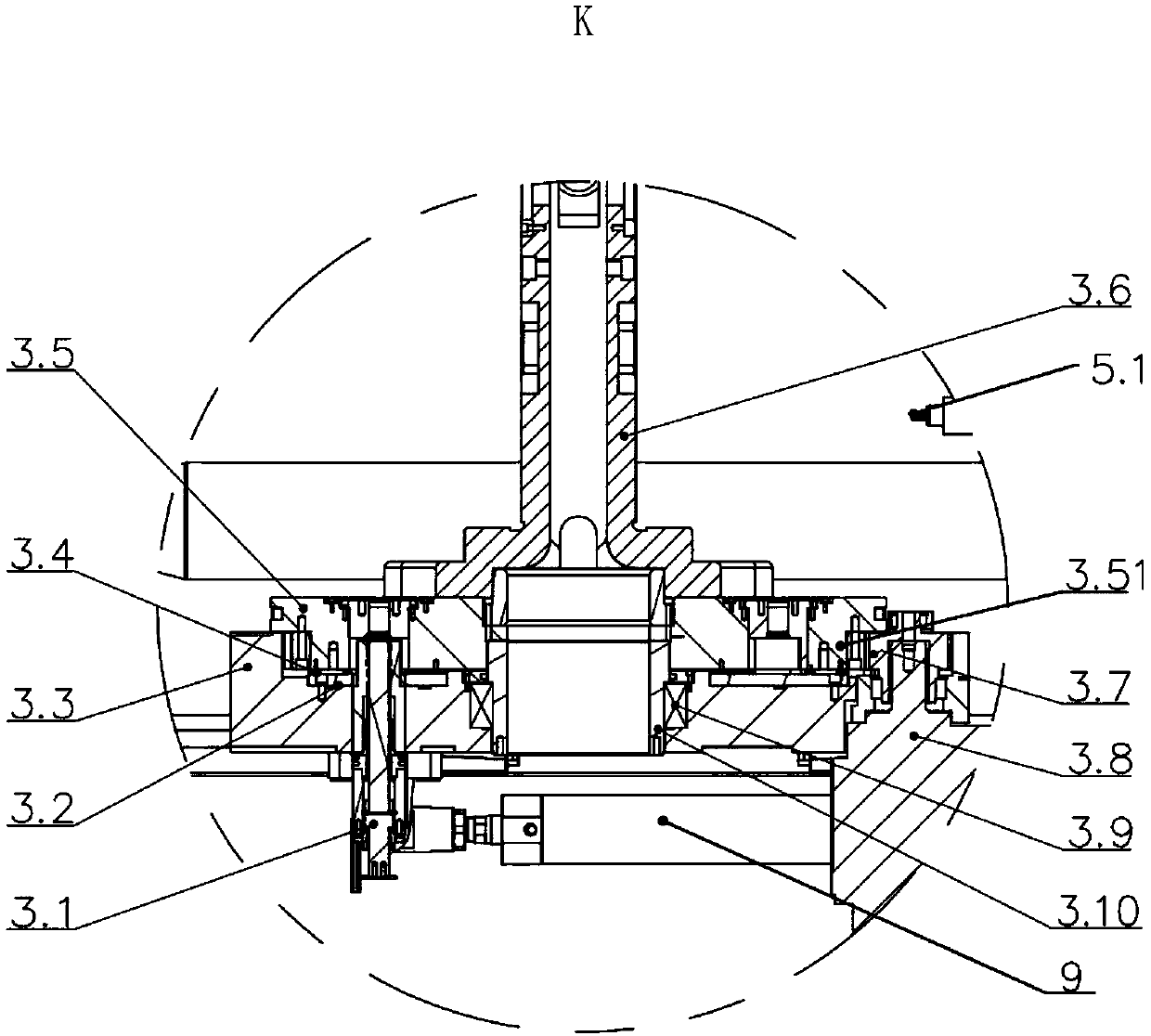

[0033] A horizontal rotary mold clamping mechanism for an injection molding machine, comprising a fixed platen 6, a movable platen 2, and a guide block 1 arranged between the movable platen 2 and the fixed platen 6 for the movable platen 2 to move back and forth relative to the fixed platen 6, and the guide block 1 is opposite to the fixed platen 6. The two sides of the movable template 2 are provided with chutes along the running direction of the movable template 2, the two sides of the bottom of the movable template 2 are provided with sliding blocks matched with the chute, and the end of the fixed template 6 far away from the movable template 2 is provided with a clamping oil cylinder 7. The piston rod end of the mold oil cylinder 7 is connected with a pull rod 4, and the end of the pull rod 4 away from the piston rod is fixed with the fixed template 6, and the clamping cylinder 7 is preferably provided with 4, which are evenly distributed on the four corners of the fixed tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com