Mounting device and mounting method of prefabricated box girder bottom web steel bar framework

A technology for reinforcement skeleton and web reinforcement, which is applied in the field of installation devices for tying web reinforcement skeletons at the bottom of prefabricated box girders. It can solve the problems of manpower and time waste in erecting and dismantling, insufficient linearity of the overall reinforcement, and small operating space for construction personnel. problems, to achieve the effect of improving installation speed and quality, simple structure, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

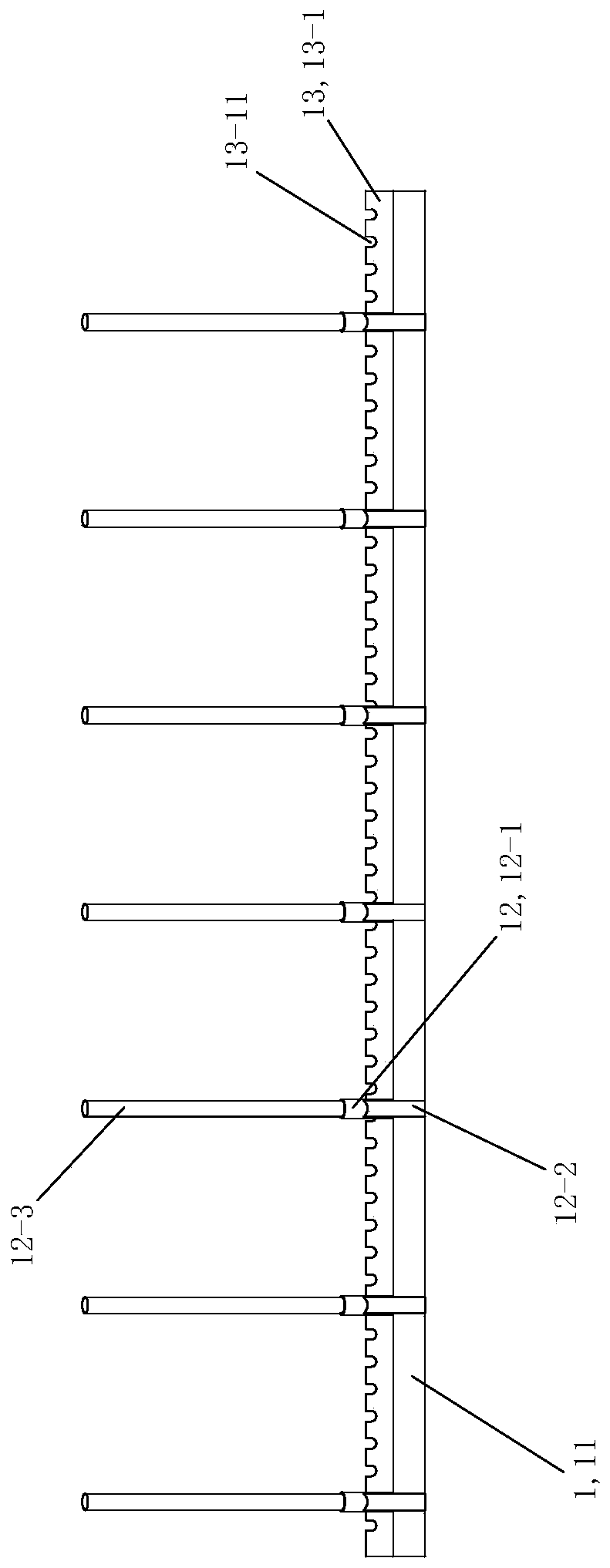

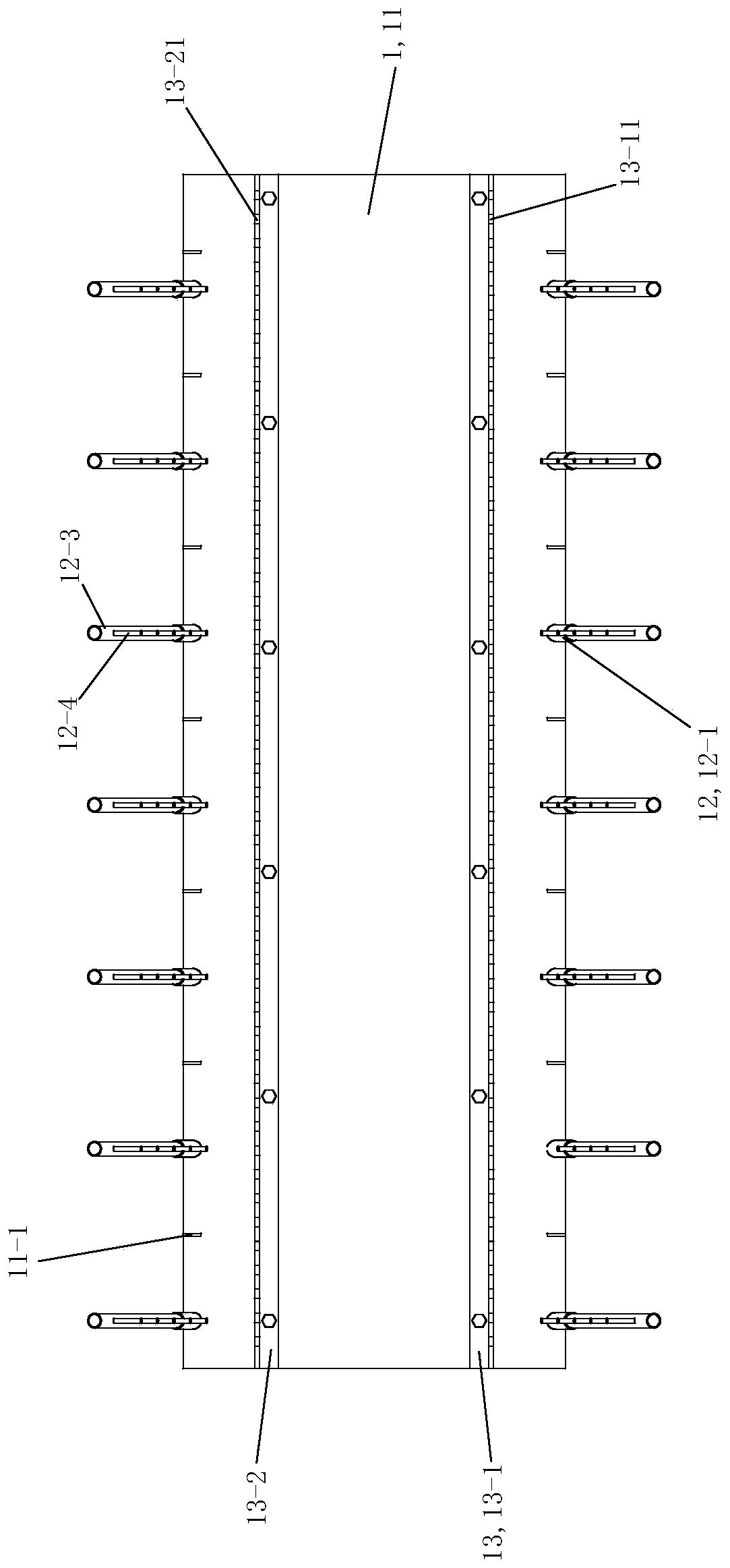

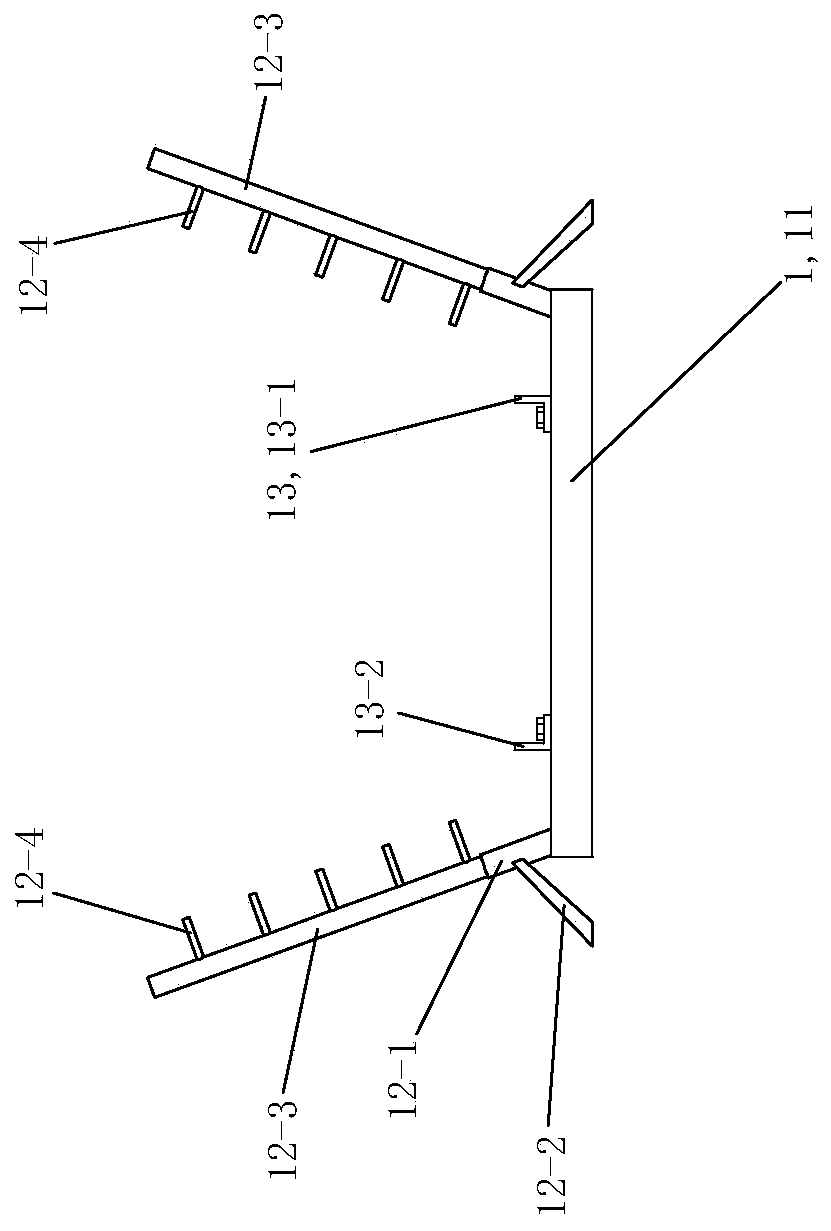

[0042] See Figure 1 to Figure 7 , The installation device of the prefabricated box girder bottom web steel skeleton of the present invention includes an installation mold 1 , a bellows positioning device 2 and a lifting frame 3 . The installation mold 1 is used for supporting and positioning the steel frame; the bellows positioning device 2 is used for quickly locating the installation position of the bellows; the lifting frame 3 is used for lifting and transferring the steel frame.

[0043] See Figure 1 to Figure 5 , the installation mold 1 includes a support platform 11 , a web steel bar support assembly 12 and a bottom plate steel bar positioning assembly 13 .

[0044] The support platform 11 is hardened with C30 concrete, with a thickness of 5 to 15 centimeters, and the thickness of this embodiment is 10 centimeters. The longitudinal length of the support platform 11 is greater than that of the prefabricated box girder, and both ends are 50 to 200 cm longer than the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com