Manufacturing method of precast slab beam

A manufacturing method and technology of plate girders, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of exposed steel bars and insufficient structural integrity of prefabricated plate girders, and achieve the effect of improving uniformity and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention introduces a method for making a prefabricated slab girder, which includes the following steps.

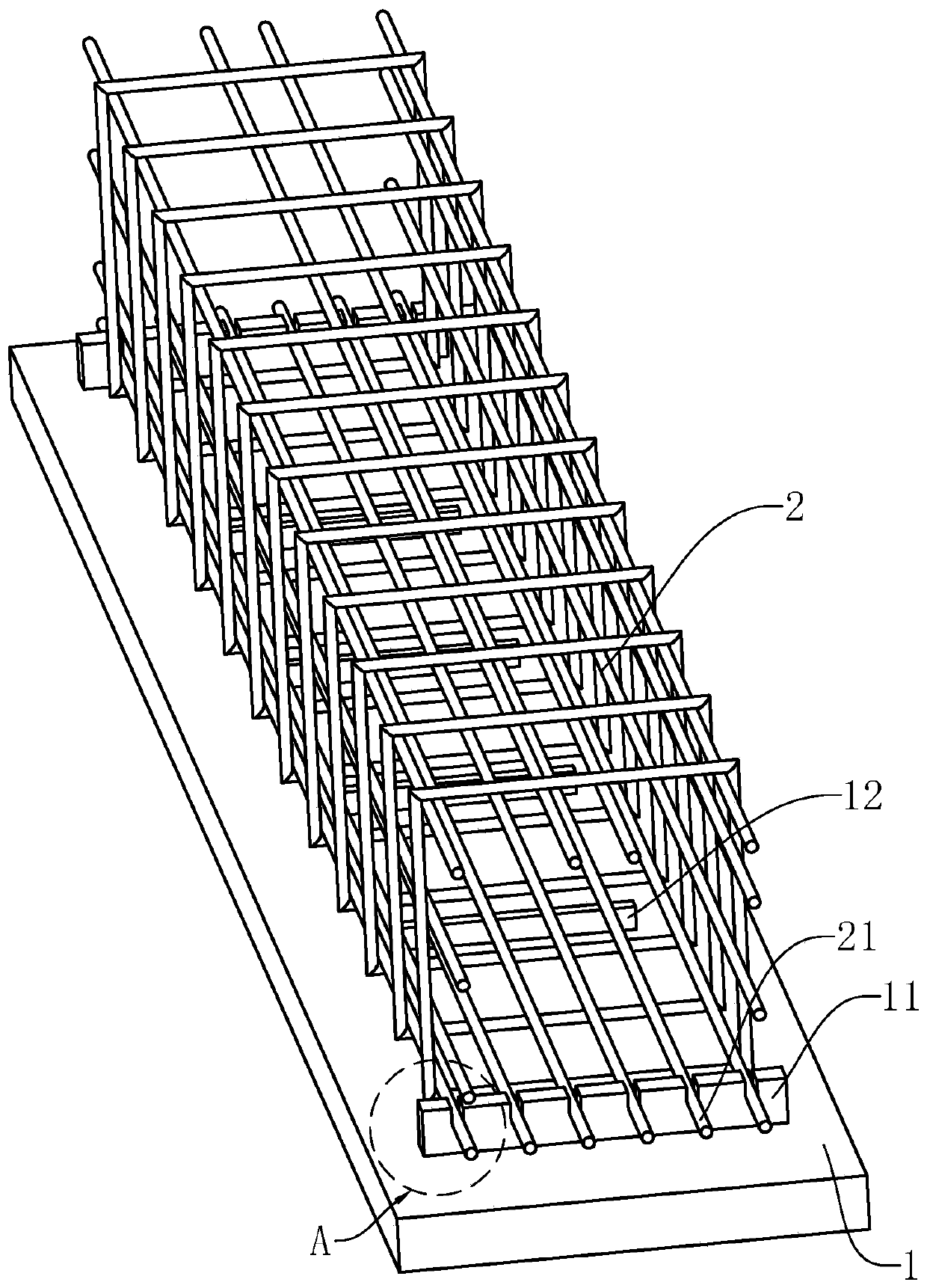

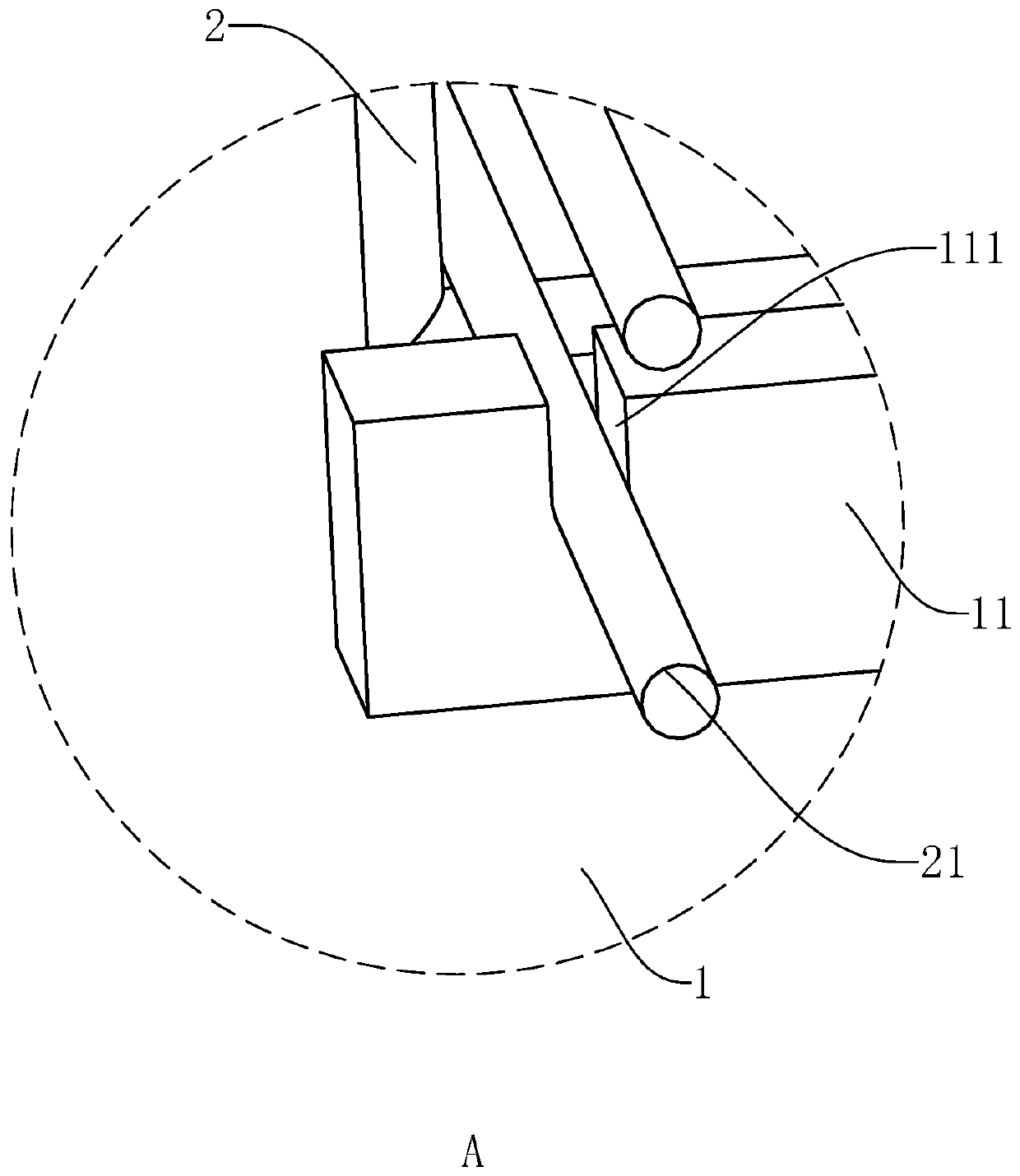

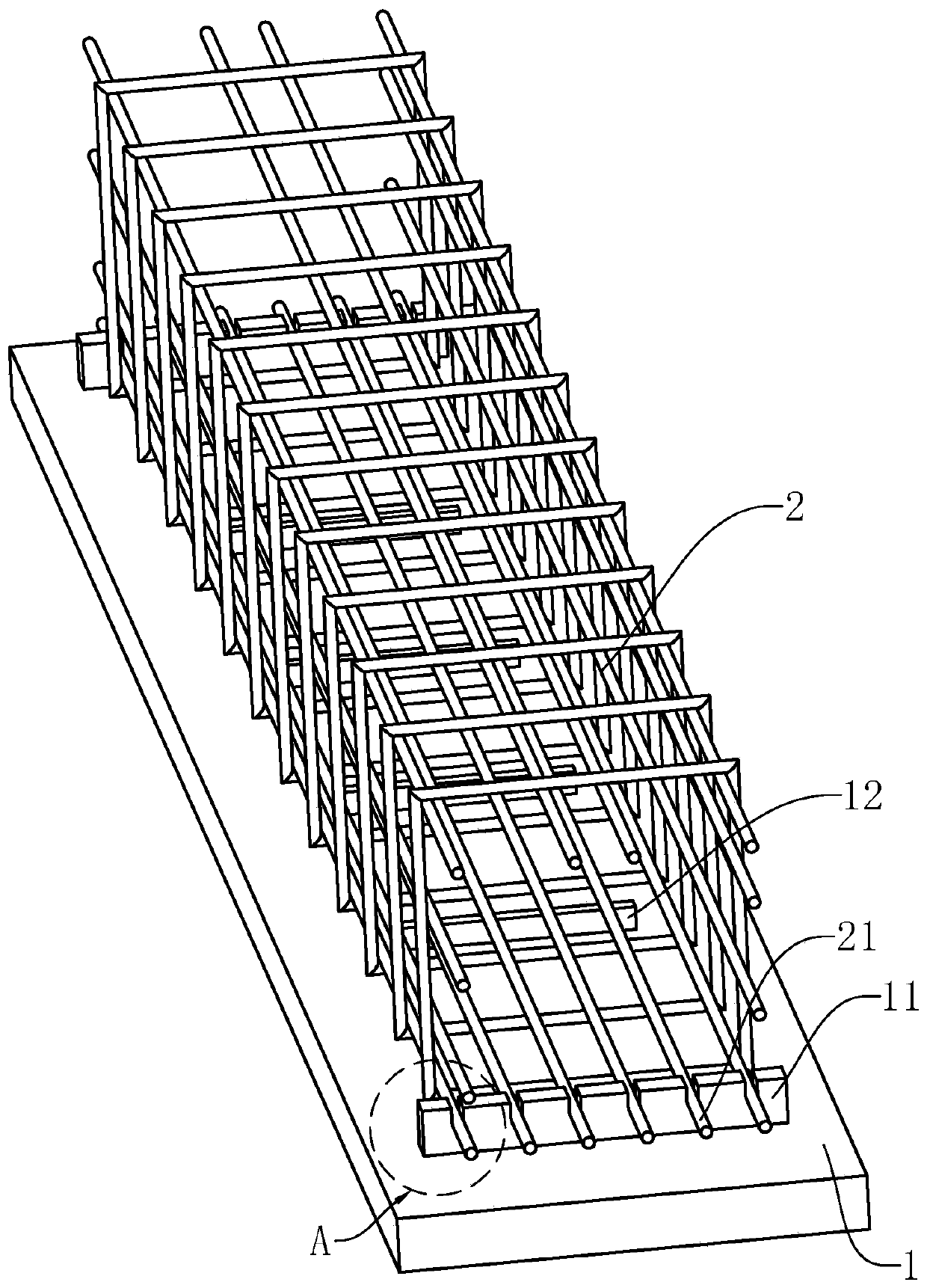

[0026] S1. Binding reinforcement cage 2. Such as figure 1 As shown, the binding reinforcement cage 2 is carried out on the horizontal prefabricated pedestal 1, and the two ends of the prefabricated pedestal 1 in the length direction are respectively fixed with support plates 11, and auxiliary supports are also placed on the prefabricated pedestal 1 between the support plates 11. Plate 12; steel cage 2 is provided with a plurality of horizontally side by side supporting steel bars 21 along the length direction of the plate girder, and the supporting steel bars 21 are bound at the lower part of the middle of the steel bar cage 2, and the two ends of the supporting steel bars 21 are lapped on the supporting plate 11, the main part of the reinforcement cage 2 is then lapped on the top of the auxiliary support plate 12. There is a certain gap between the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com