T-shaped beam casting special mold and using method thereof

A mold and mold-oriented technology, applied in molds, mold fixtures, mold auxiliary parts, etc., can solve the problems of insufficient practicability, low quality of T-beams, and insufficient functions, saving internal space, perfect functions, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

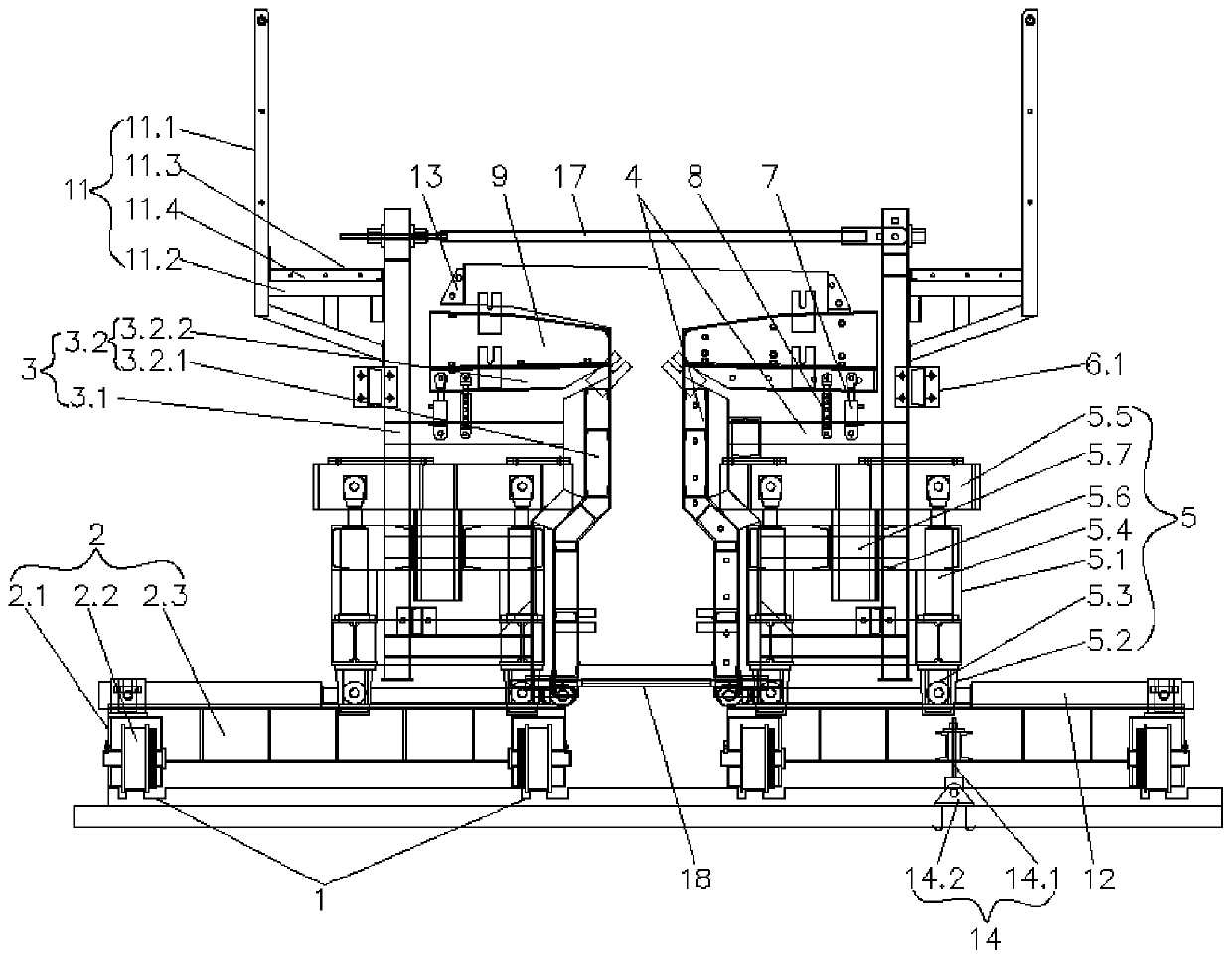

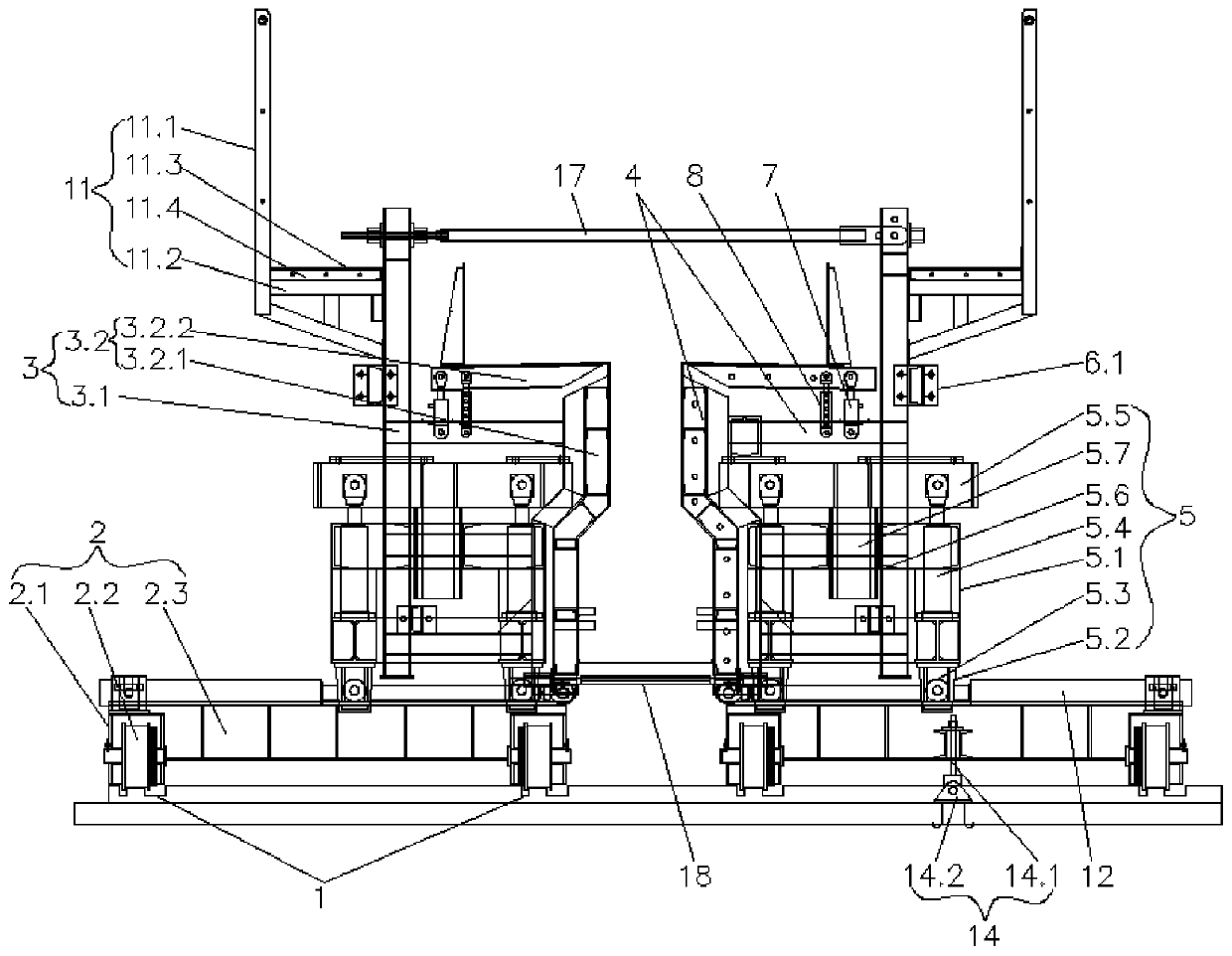

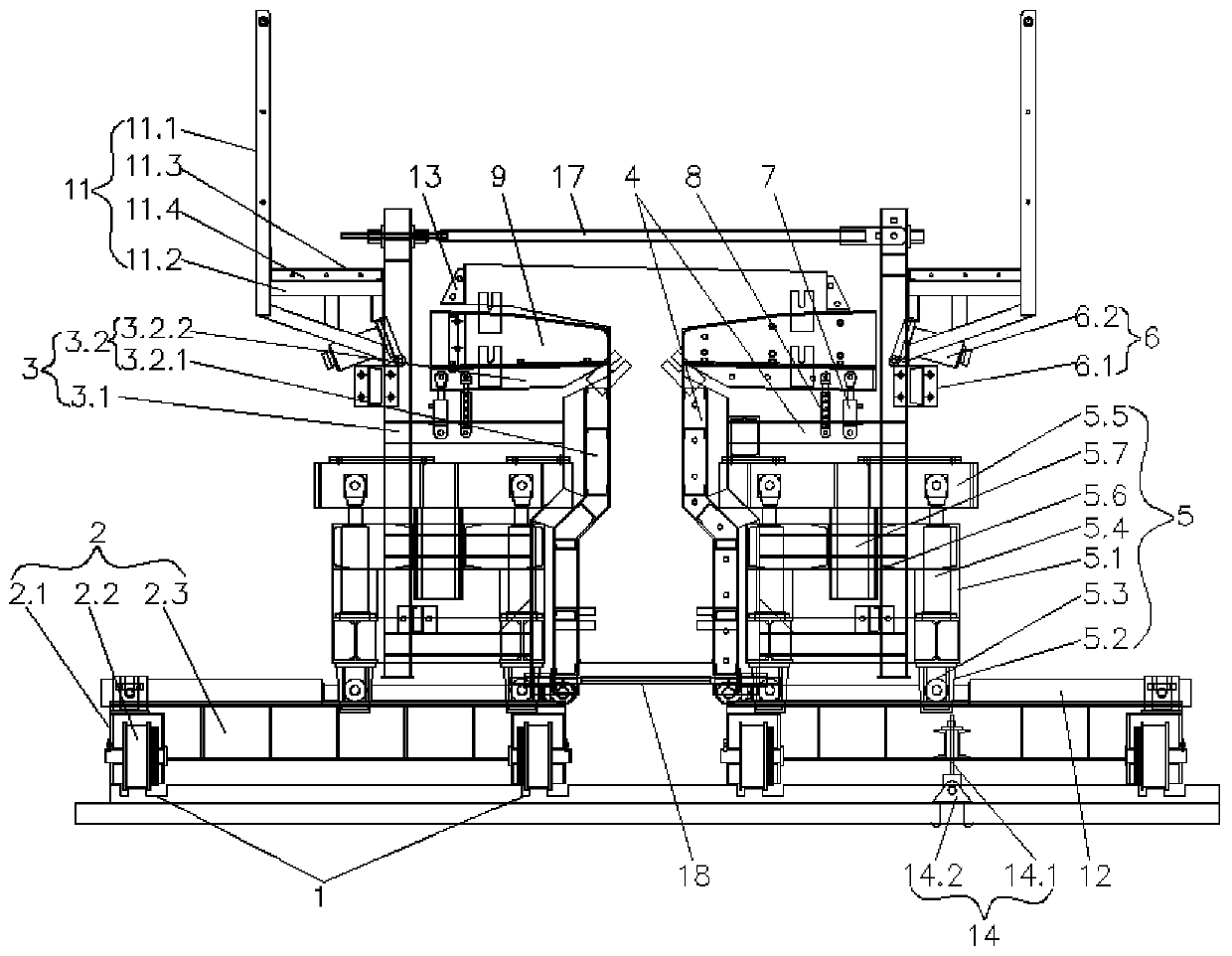

[0059] Such as Figures 1 to 11 As shown, this embodiment provides a special mold for T-shaped beam pouring, including a guide rail 1, on which a walking trolley 2 is slidably arranged to cooperate with it, and the walking trolley 2 is symmetrically provided with a mold for forming a T-shaped beam. The left side mold 3, the right side mold 4 and both ends of the beam 15, the left side mold 3 includes a frame 3.1 and a panel 3.2 detachably connected to the inner side of the frame 3.1, and the walking trolley 2 is provided with a Mold guiding device 5 with high travel space, the mold guiding device 5 can slide left and right, the outer ends of the two frames 3.1 are equipped with a number of flip-type demoulding mechanisms 6 above the mold guiding device 5, and the two frames 3.1 are equipped with automatic slope adjustment Mechanism 7 and locking mechanism 8, the tops of automatic slope adjustment mechanism 7 and locking mechanism 8 are all hinged on the bottom of the rotatable...

Embodiment 2

[0062] Such as Figures 1 to 10 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, two guide rails 1 are correspondingly arranged under the left mold 3 and the right mold 4, and the walking trolley 2 includes several The guide slide seat 2.1 arranged along the length direction of the guide slide track 1 is provided with a drive wheel 2.2 that cooperates with the guide slide track 1, and the corresponding two guide slide seats located under the left mold 3 and the right mold 4 2.1 is connected with a side guide rail 2.3, and the side guide rail 2.3 and the guide rail 1 are perpendicular to each other. The mold guide device 5 includes a traverse car 5.1, and the side guide rails 2.3 are equipped with a horizontal oil cylinder 12 and a piston rod of the horizontal oil cylinder 12. Connected to the bottom of the traversing vehicle 5.1, the four corners of the bottom of the traversing vehicle 5.1 are provided with mounting frames 5.2, and the...

Embodiment 3

[0065] Such as Figures 1 to 3 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the flip-type demoulding mechanism 6 includes a base 6.1 arranged on the outer end of the frame 3.1, and an ejection cylinder 6.2 is hinged on the base 6.1. The ejection cylinder 6.2 acts on the rib plate position of the T-beam.

[0066] In this embodiment, when the mold is demoulded, the ejector cylinder acts on the rib plate of the T-beam, and the mold is ejected by using the reverse thrust. When the mold is closed, the ejector cylinder is turned over to the outside of the base to avoid ejection. The oil cylinder collides with steel bars and other components to ensure smooth mold closing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com