Material transferring device

The technology of a transfer device and a rotating device is applied in the field of mechanical processing, which can solve the problems of increasing labor costs, high work intensity, and low efficiency of workpiece processing, so as to reduce labor and production costs, avoid personal safety accidents, and meet the needs of large-scale production. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

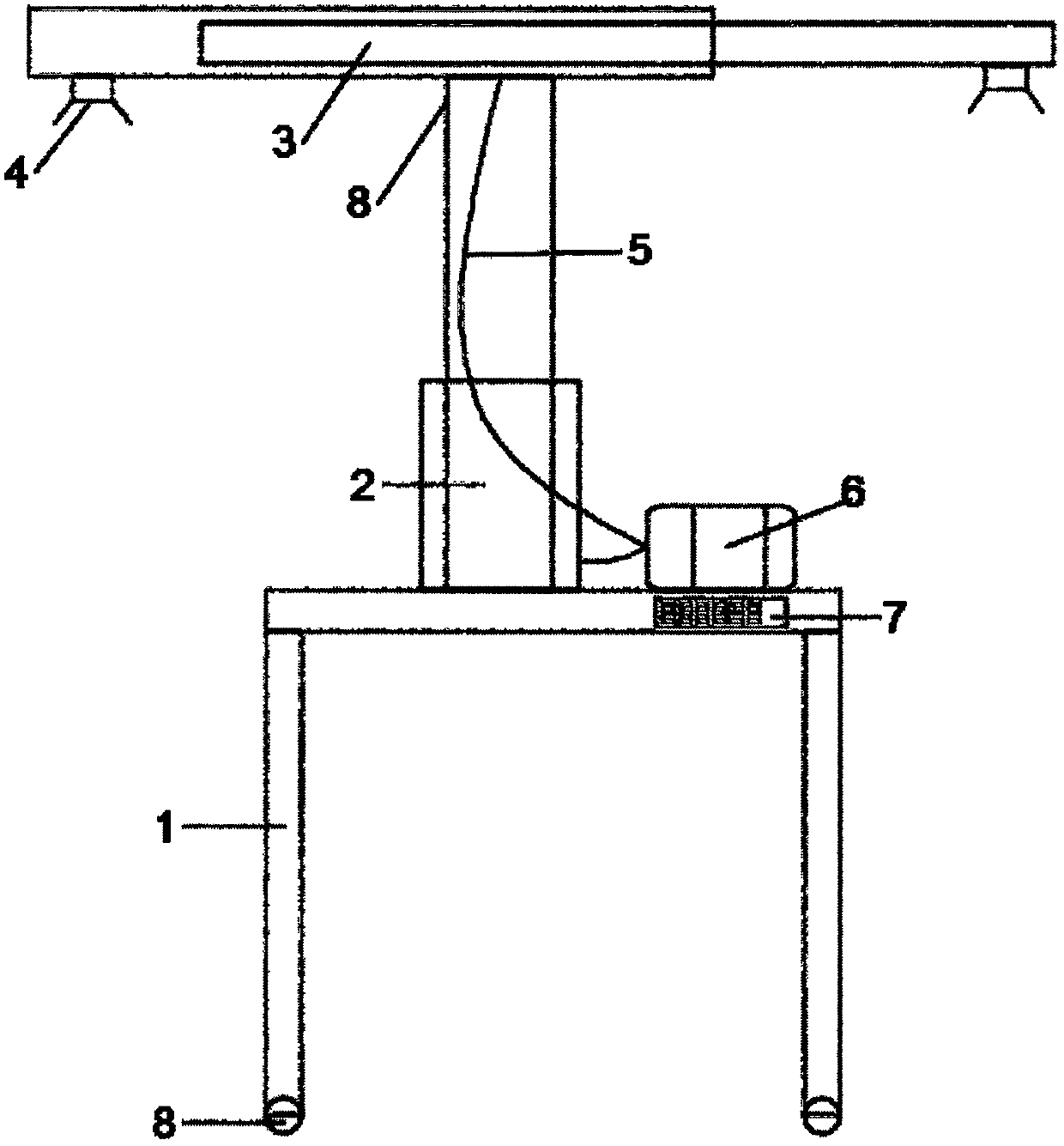

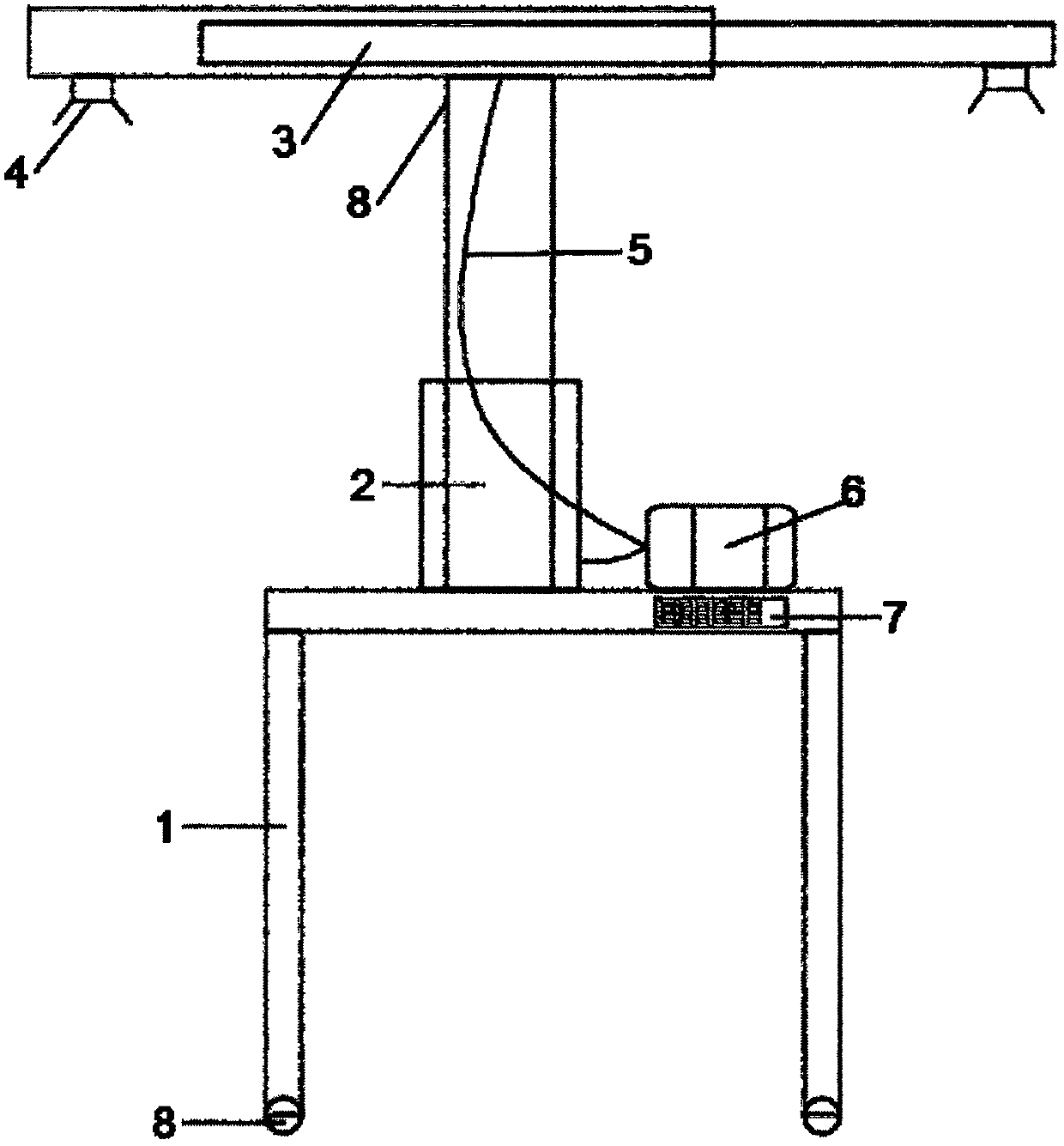

[0015] Such as figure 1 As shown, the present invention provides a kind of material transferring device, comprises workbench 1, rotating device 8 and motor 6, and described motor 6 is controlled by controller 7, and described motor 6 is fixed on the workbench 1, and described controller 7 On the right side of the workbench 1, the rotating device 8 includes a vertical telescopic rod 2 and a horizontal telescopic rod 3, the vertical telescopic rod 2 is fixed on the workbench 1, and the two ends of the horizontal telescopic rod 3 are installed with The suction cup 4, the vertical telescopic rod 2 and the horizontal telescopic rod 3 are connected to the motor 6 through a control line 5, and universal wheels 8 are installed on the bottom of the workbench 1 .

[0016] The vertical telescopic rod 2 and the horizontal telescopic rod 3 are flexible in length.

[0017] The opening and closing of the sucker 4 is controlled by a motor 6 .

[0018] The extension range of the horizontal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com