Water quality sensor with automatic production function

A sensor and water quality technology, applied in automatic detection under the control of tableware washing machine/rinsing machine, tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, etc., can solve the problem of poor production efficiency, There are no problems such as automated production and cost increase, achieving the effect of reducing labor and production costs, improving production speed and efficiency, and ensuring quality and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to achieve the above-mentioned purpose and effect, the technical means and the structure thereof adopted in the present invention are hereby illustrated in detail with respect to preferred embodiments of the present invention. Its structure and function are as follows, so as to fully understand.

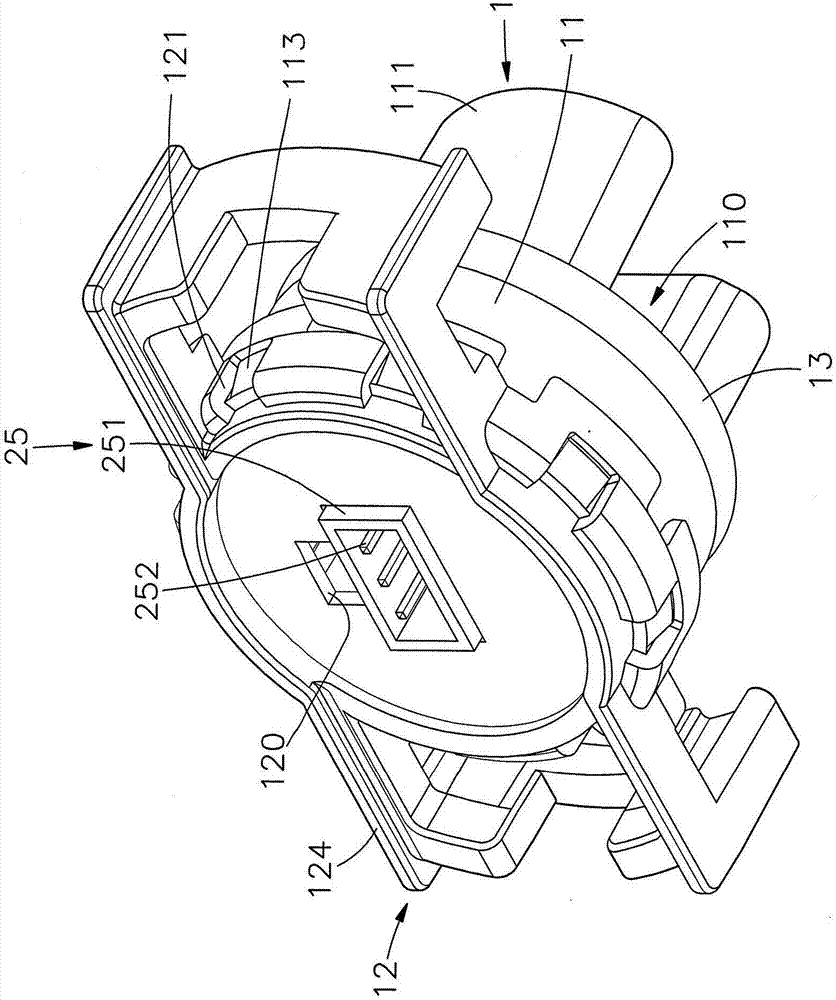

[0036] see figure 1 , figure 2 , image 3 , Figure 4 As shown, they are the three-dimensional appearance diagram of the present invention, the three-dimensional appearance diagram of another angle of view, the three-dimensional exploded view and the three-dimensional exploded view of another angle of view. It can be clearly seen from the figure that the automatic production water quality sensor of the present invention The device includes a housing 1 and a sensing module 2, wherein:

[0037] The casing 1 has a base 11 made of a light-transmitting material, and protruding parts 111 extend in the same direction on both sides of the base 11, and an open channel 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com