Full-automatic high-recovery-rate salt separation integrated system and method

A high recovery rate, integrated system technology, applied in chemical instruments and methods, water/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of high investment and operating costs, high operating costs, and poor economy. To achieve the effect of saving manpower and production costs, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

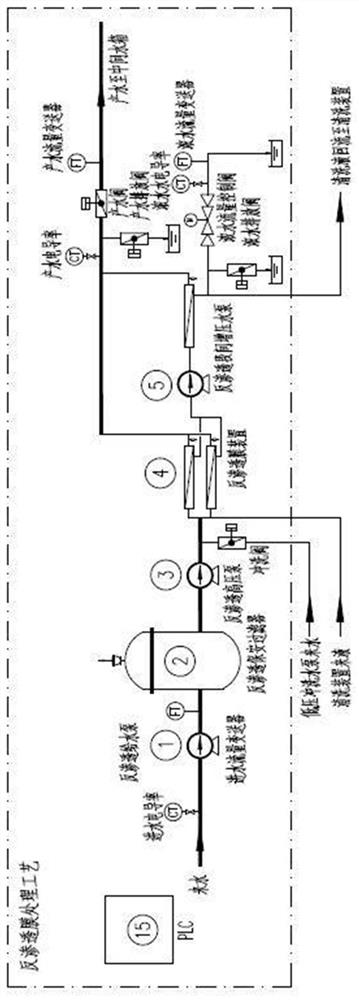

[0022] Such as figure 1 As shown, the reverse osmosis membrane treatment unit is equipped with a reverse osmosis water inlet pump 1, a reverse osmosis security filter 2, a reverse osmosis high-pressure pump 3, a reverse osmosis membrane device 4, an inlet water conductivity meter, a product water conductivity meter, inlet water, concentrated water And product water flow transmitter, concentrated water flow control valve, product water discharge valve and concentrated water discharge valve, etc.

[0023] The reverse osmosis high-pressure pump 3 is set to start with frequency conversion, and the flow can be adjusted according to the incoming water temperature and water quality. When the equipment is shut down or after a period of operation, it will automatically enter low-pressure flushing. According to the operating conditions, the low-pressure flushing time can be controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com