Composite unit for bone implant, porous scaffold and preparation method

A technology of bone implants and porous scaffolds, applied in bone implants, medical science, tissue regeneration, etc., can solve the problems of fewer implant designs and only consider uniaxial loads, etc., to shorten the time-consuming design, The structure is simple and the effect of improving the ability to resist bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

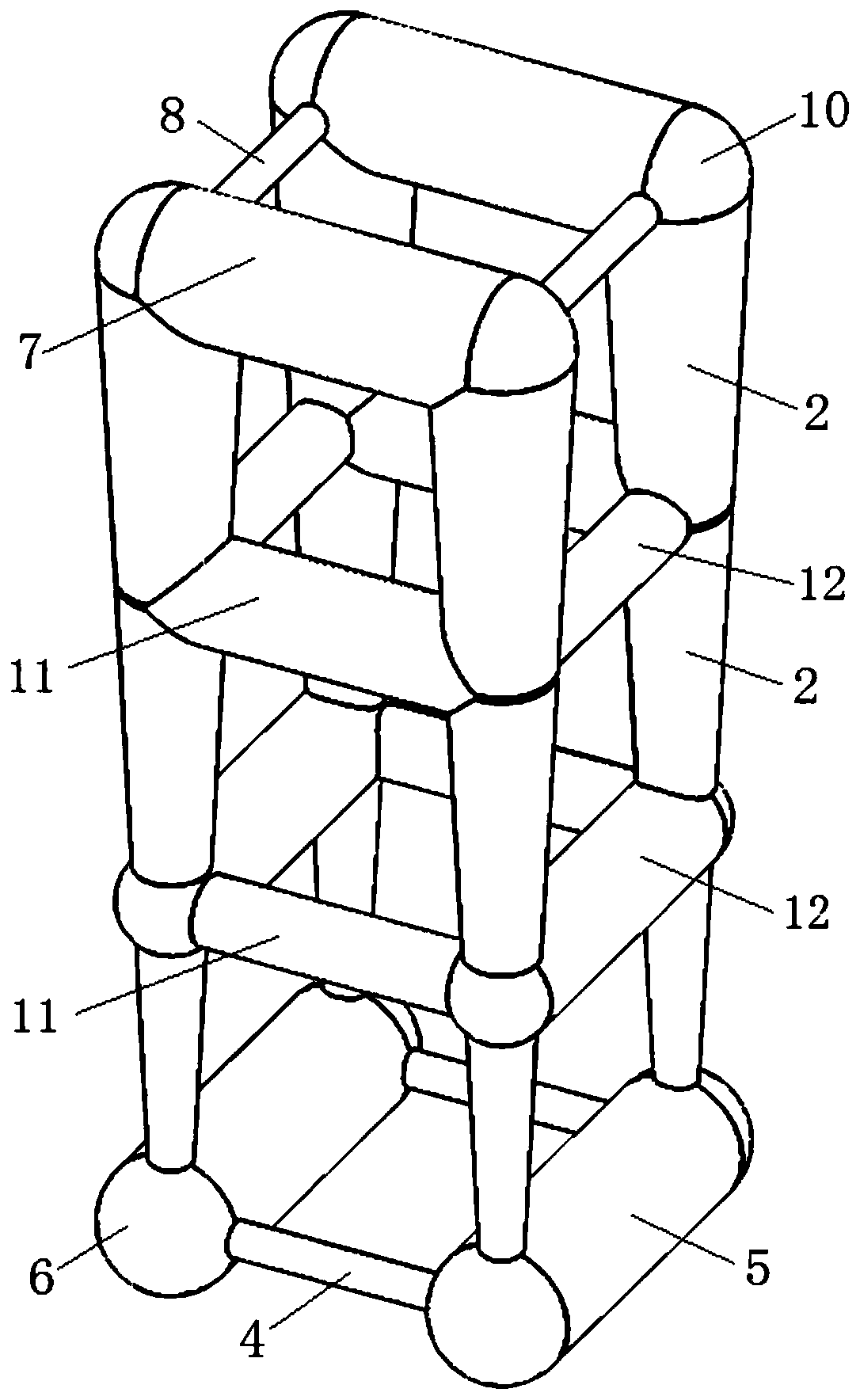

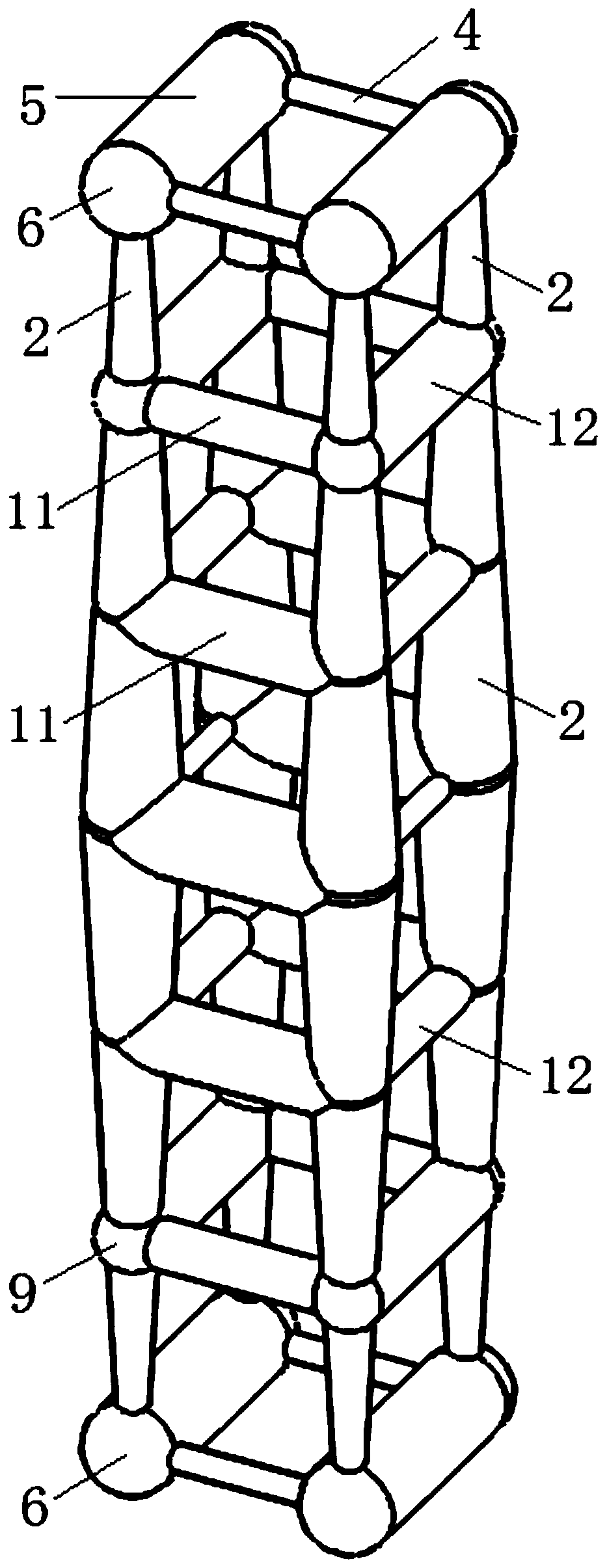

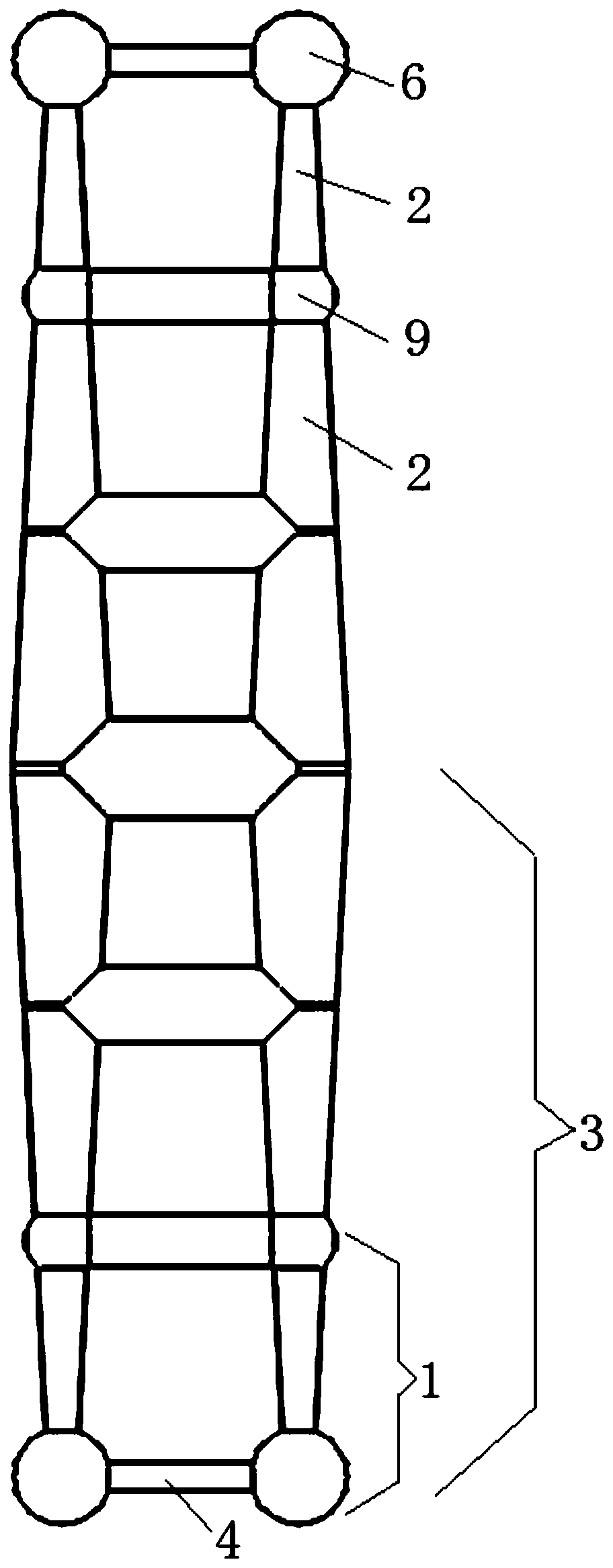

[0033] Such as figure 1 -As shown in 4, a composite unit for bone implants includes several structural units 1. The structural units 1 include a first receiving surface, a second receiving surface and a connecting rod 2 in the shape of a truncated cone. One end of the connecting rod 2 is respectively connected with the first receiving surface, the other ends of the plurality of connecting rods 2 are respectively connected with the second receiving surface, and the radius of one end surface of the connecting rod 2 is smaller than the radius of the other end surface, The structural units 1 merge in sequence to form the porous structure 3, that is, the second receiving surface and the first receiving surface of the adjacent structural unit 1 merge in sequence to form the porous structure 3. The radius of the two ends of the connecting rod 2 Ascending from the head end to the tail end of the porous structure 3, the second bearing surfaces of the tail ends of the two porous structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com