Feed additive replacing fish oil and preparation method thereof

A feed additive and fish oil technology, applied in animal feed, additional food elements, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

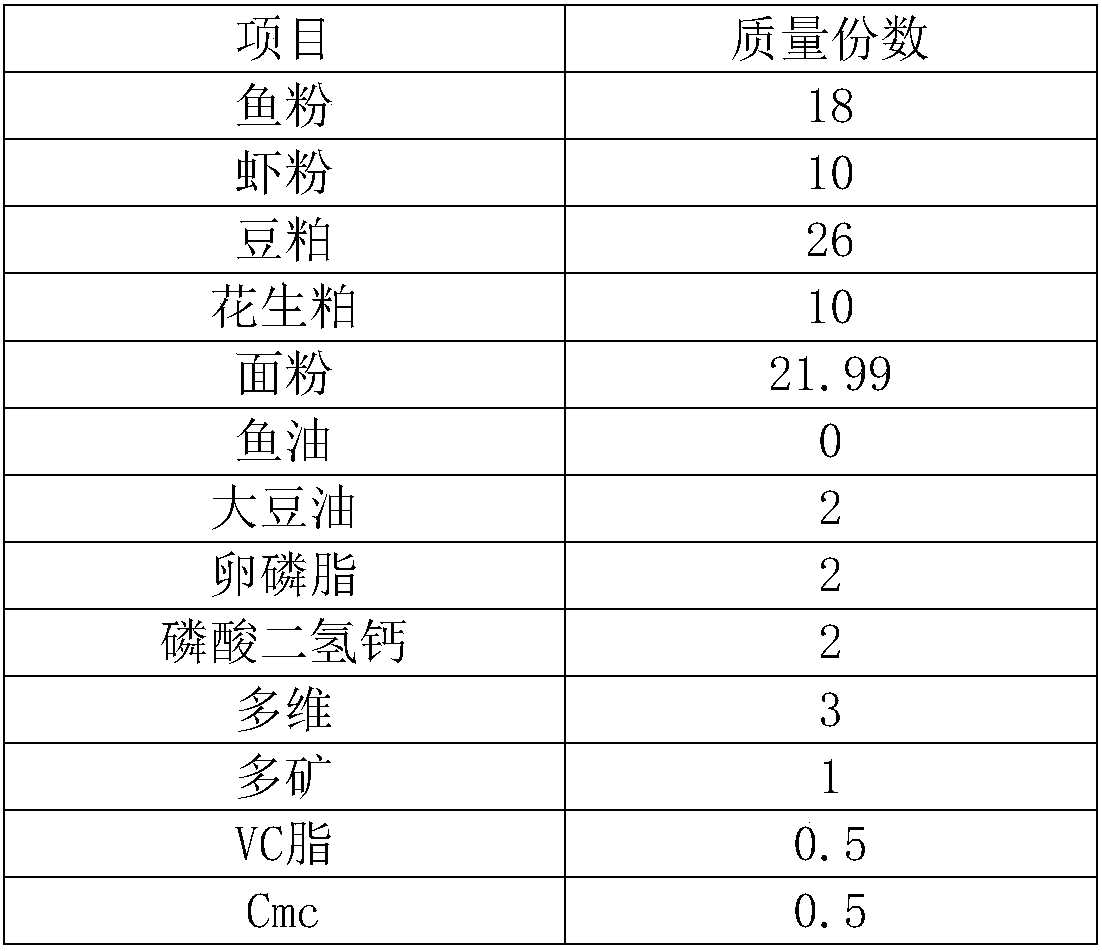

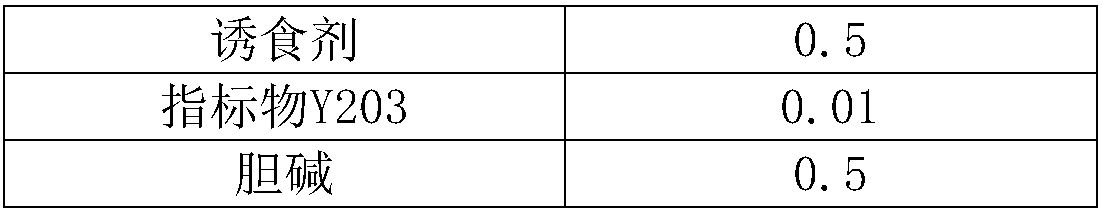

Image

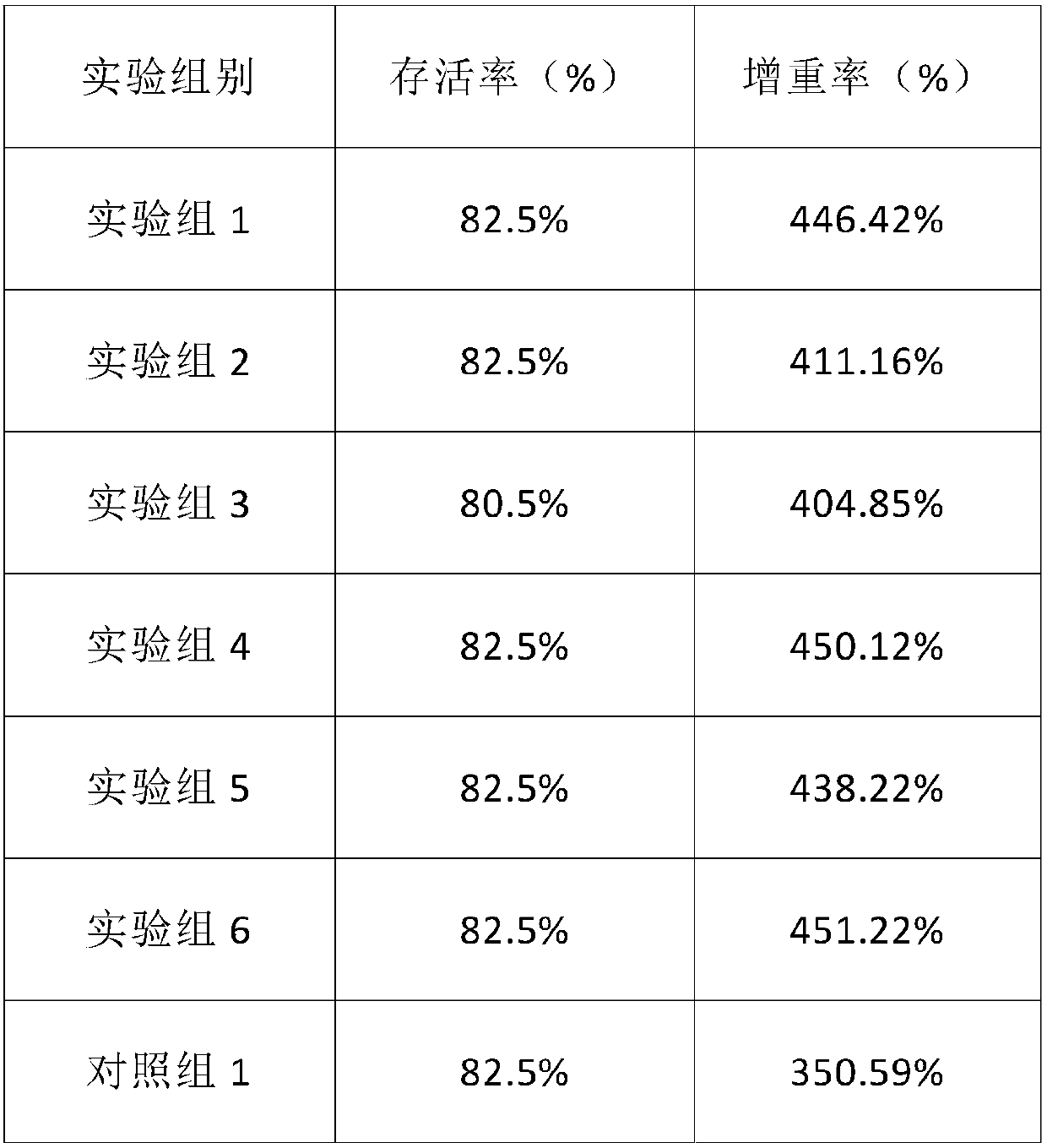

Examples

Embodiment 1

[0061] A. The preparation method of glycerol phosphatidylcholine: at a temperature of 35° C., take 500 g of phosphatidylcholine, dissolve it in 10000 ml of ethanol, add 250 ml of sodium methoxide ethanol (35% mass fraction) solution, react for 6 hours, and evaporate the solvent. 440 g of a reaction product containing glycerol phosphatidylcholine was obtained. After testing, the content of glycerol phosphatidylcholine in the reaction product was 83.4%.

[0062] B. The preparation method of acetylated phosphatidylethanolamine: take 100g of phosphatidylethanolamine, add 5g of acetic anhydride, the reaction temperature is 72°C, and the reaction time is 30min. After the acylation is completed, 1 g (30% mass fraction) of sodium hydroxide solution is added for neutralization. The oil phase was separated with n-hexane, cold analysis and filtration in cold acetone at 5°C, and the oil phase was extracted again with cold methanol at 5°C, and the insoluble part was 40 g of acetylated phos...

Embodiment 2

[0064] Take 100g of soybean oil bottoms, add 50ml of sodium methoxide ethanol (35% mass fraction) solution, react at 65°C for 6h, evaporate the solvent, and adjust to neutral with acetic acid. Then add 5g of acetic anhydride, raise the temperature to 72°C, and the reaction time is 30min. The final analysis determined that the content of glycerol phosphatidylcholine in the product was 4.13%, and the content of acetylated phosphatidylethanolamine was 1.86%, so that a feed additive with a weight ratio of glycerol phosphatidylcholine:acetylated phosphatidylethanolamine of 2.22:1 was obtained.

Embodiment 3

[0066] Take 200g of soybean lecithin oil, add 400ml of sodium methoxide ethanol (35% mass fraction) solution, react at 60°C for 5.5h, evaporate the solvent, and adjust to neutral with acetic acid. Then add 11g of acetic anhydride, raise the temperature to 70°C, and the reaction time is 45min. Final analysis determined glycerol phosphatidylcholine (20.68%) and acetylated phosphatidylethanolamine (9.02%) to obtain a feed additive with a weight ratio of glycerol phosphatidylcholine: acetylated phosphatidylethanolamine of 2.29:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com