On-line testing device for dynamic friction performance of paired angular contact ball bearings

An angular contact ball bearing and dynamic friction technology, which is applied in mechanical bearing testing, measuring devices, testing of mechanical components, etc., can solve the problems of inability to measure the friction torque of a single bearing, inconvenient adjustment of the axial preload, and centering of the sleeve Locking difficulties and other problems can be achieved to protect the contact damage, overcome the interference caused by the motion state of the bearing, and simplify the experimental steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

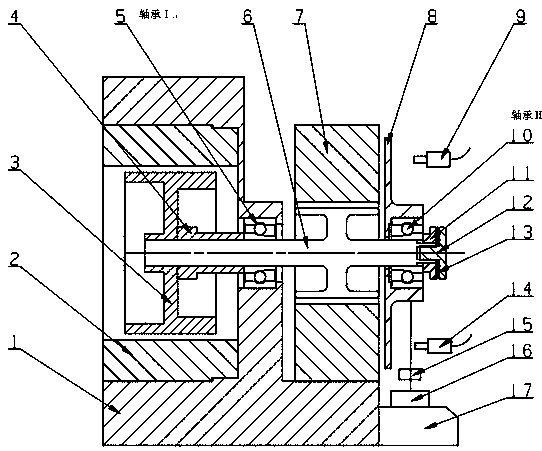

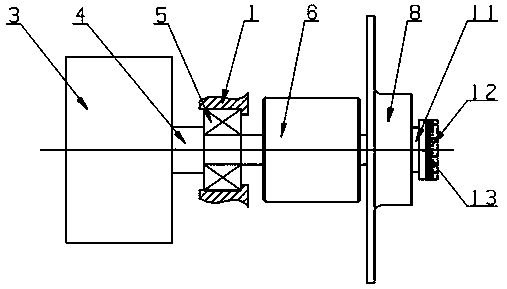

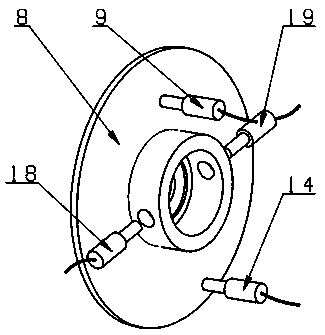

[0023] Such as figure 1 , 2 , 3, 4, and 5, an online test device for dynamic friction performance of paired angular contact ball bearings, including base 1, motor 2, 3, support shaft 6, paired bearings 5, 10, loading mechanism and measurement part. The stator 2 of the motor is fixed on the base 1, the motor rotor 3 is directly connected with the support shaft 6, the support shaft 6 is installed in the hole of the air bearing 7 in the radial direction, and the thrust surface of the air bearing 7 and the thrust disc 8 limit the support shaft The displacement of 6 to the left, the bearing I5 and the base 1 limit the displacement of the support shaft 6 to the right to realize the axial positioning of the shaft system. The low friction torque rotates, driving the paired bearings 5 and 10 to rotate; the measuring part has two non-contact displacement sensors 9 and 14 installed in front of the thrust disc 8, which can measure the distance between the thrust disc 8 and the radial a...

Embodiment 2

[0024] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com