Refrigerator

A technology of refrigerators and ducts, which is applied in the direction of household refrigerators, coolers, lighting and heating equipment, etc. It can solve the problems of limited sound insulation effect, inability to completely seal the wrapped sound insulation cotton, and noise leakage, so as to improve the sound quality experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

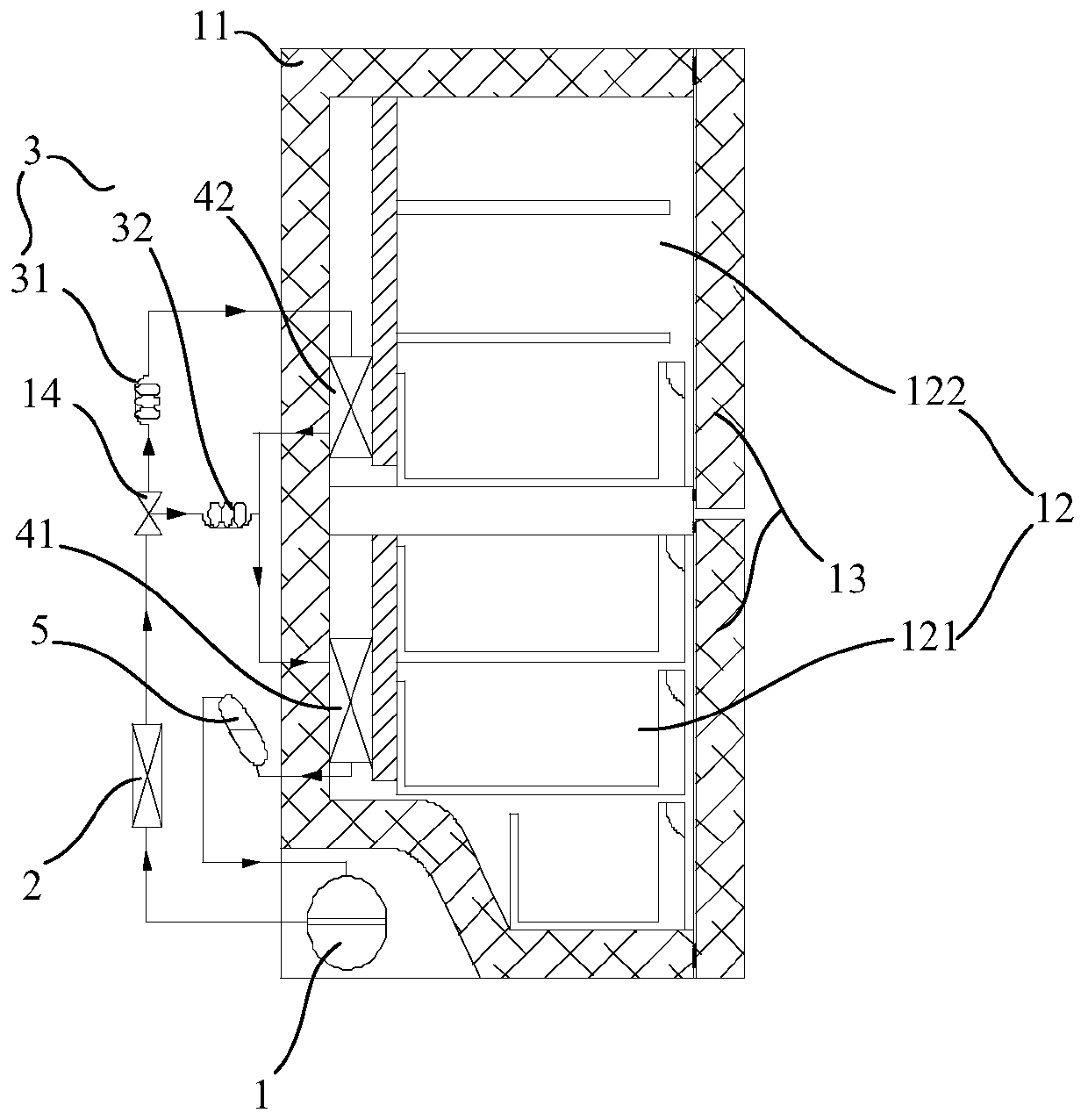

[0033] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 as well as Figure 8 As shown, the embodiment of the present invention provides a refrigerator, including a box body 11, a storage room 12 located in the box body 11, and a door 13 for opening and closing the storage room; the storage room 12 includes a storage room located in the box body 11 The refrigerating chamber 121 on the upper side and the freezing chamber 122 located on the lower side of the box body 11 also include a refrigeration system that provides cooling capacity for the storage chamber. The refrigeration system includes a compressor 1, a condenser 2, a throttling device 3, and an evaporator 4. An accumulator 5 is provided between the outlet of the chamber evaporator 41 and the suction port of the compressor 1 . Among them, such as image 3As shown, in this embodiment, the evaporator 4 includes a freezer evaporator 41 and a refrigerator evaporator 42, and the high-temperatu...

Embodiment 2

[0051] Such as figure 2 , image 3 , Figure 9 as well as Figure 10 As shown, the embodiment of the present invention provides a refrigerator, and the refrigerator also includes a box body 11, a storage room 12 located in the box body 11, and a door body 13 for opening and closing the storage room; the storage room 12 includes a The refrigerating chamber 121 on the upper side of the casing 11 and the freezing chamber 122 positioned on the lower side of the casing 11 also include a refrigeration system that provides cooling capacity for the storage chamber. The refrigeration system includes a compressor 1, a condenser 2, a throttling device 3 and The evaporator 4, wherein the evaporator 4 includes a freezer evaporator 41 and a refrigerating room evaporator 42, the freezing room evaporator 41 and the refrigerating room evaporator 42 are in communication, and the outlet of the freezing room evaporator 41 is connected to the suction port of the compressor 1 A liquid reservoir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com