Multifunctional valve, zero-cold-water water heater and water flow control method

A technology of multi-function valve and water heater, which is applied in the fields of multi-function valve, water flow control and zero cold water water heater, can solve the problems of low control accuracy and achieve the effect of accurate outlet water temperature and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

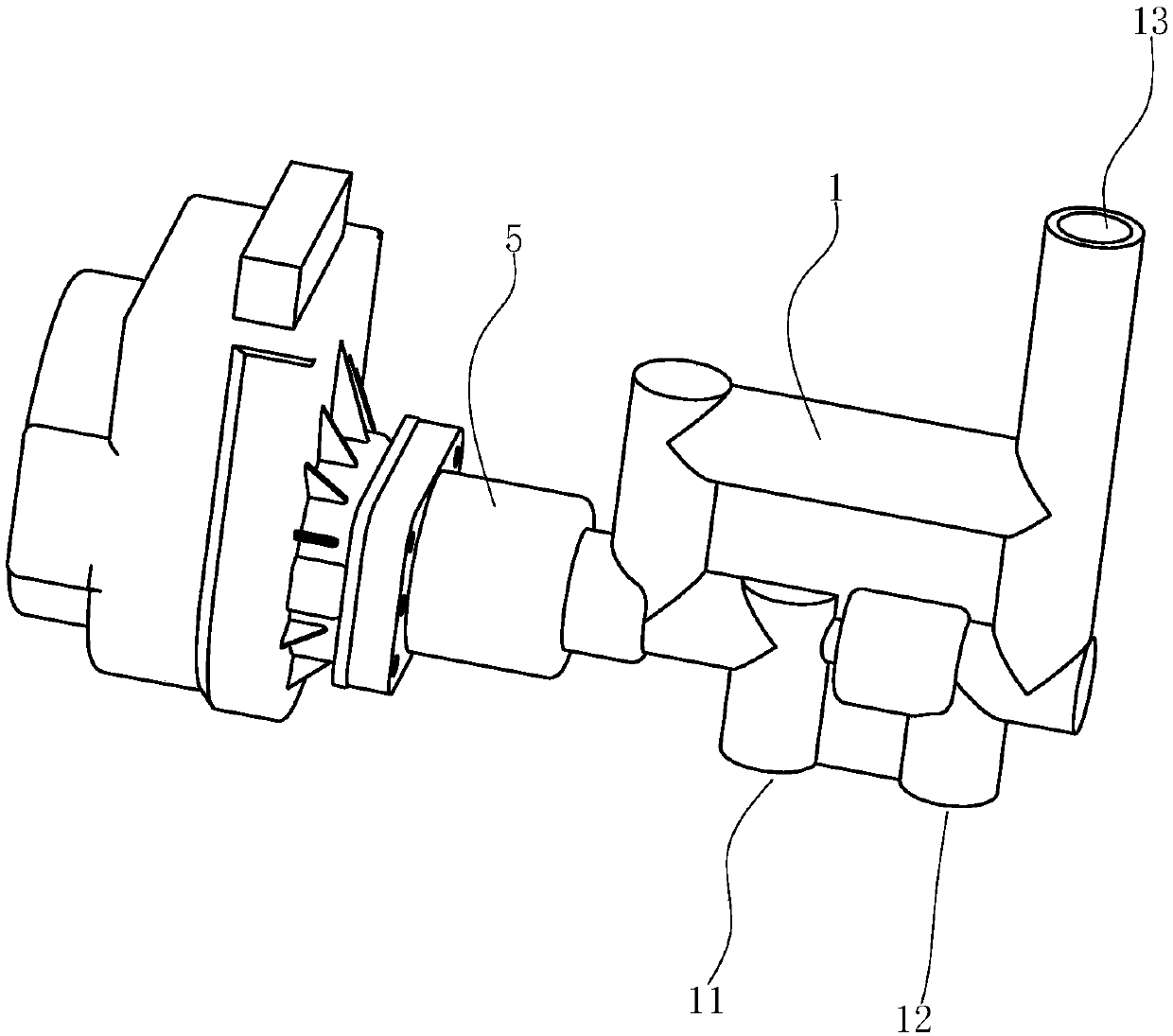

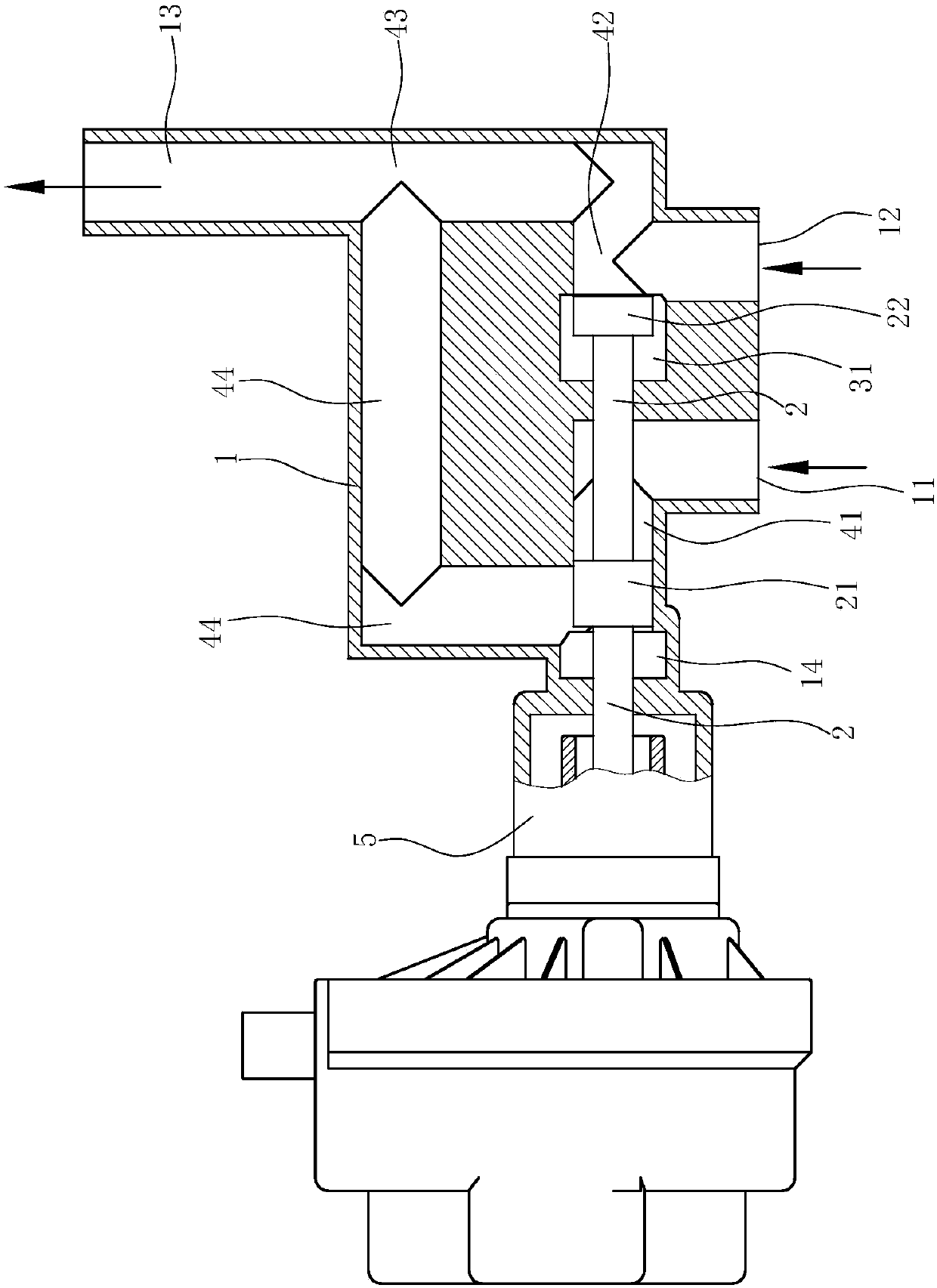

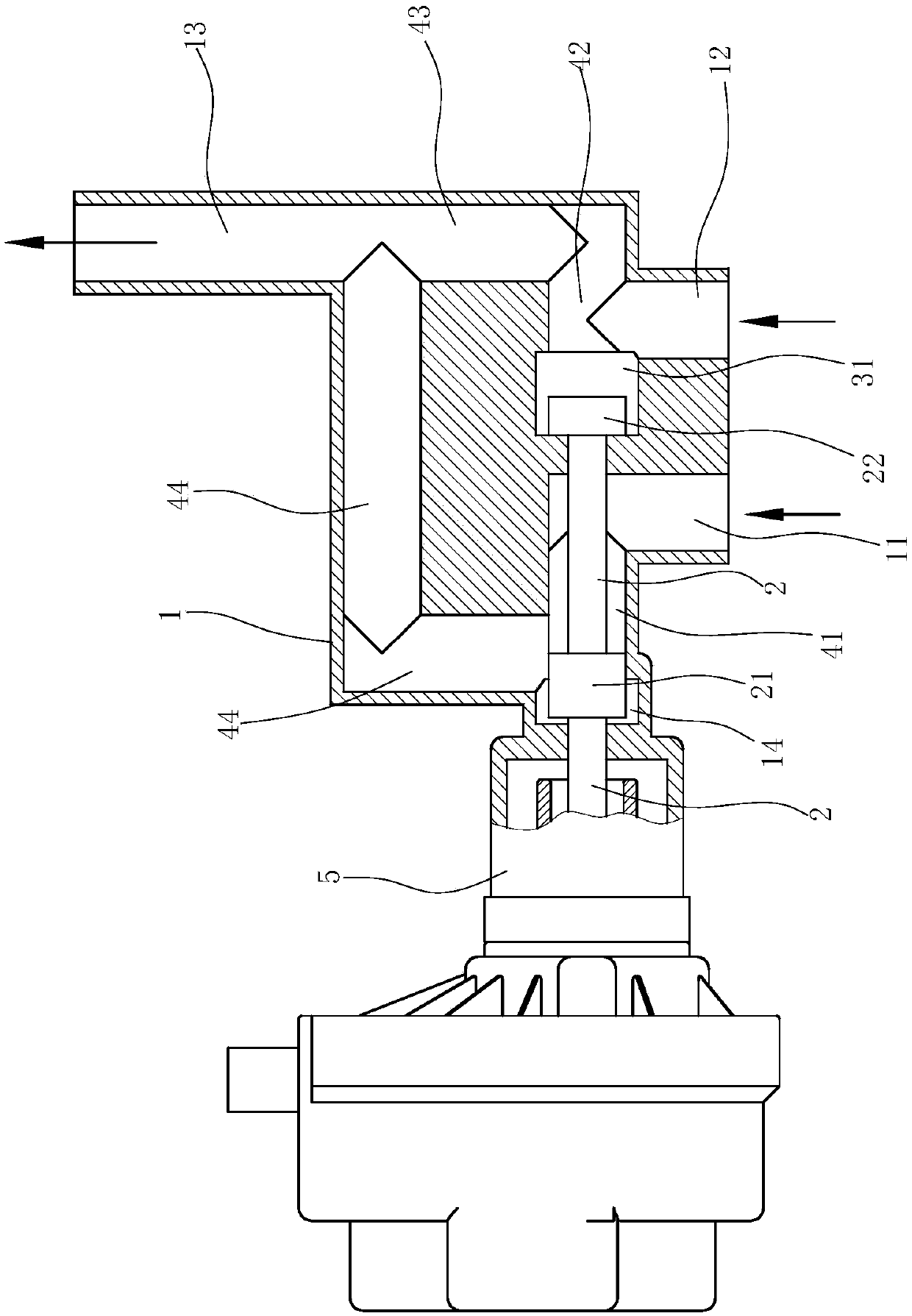

[0031] Such as Figure 1 to Figure 3 As shown, the multi-function valve includes:

[0032] The valve body 1 is provided with a first water inlet 11, a second water inlet 12 and a water outlet 13 communicating with the valve cavity of the valve body 1;

[0033] The valve seat 3 is arranged in the valve chamber of the valve body 1, and divides the valve chamber into a first water inlet chamber 41 communicated with the first water inlet 11 and a second water inlet chamber communicated with the second water inlet 12. chamber 42, a water outlet chamber 43 communicating with the water outlet 13, and a circulation chamber 44 communicating with the first water inlet chamber 41 and the water outlet chamber 43, and the second water inlet chamber 42 communicating with the water outlet chamber 43 . The valve seat 3 is also provided with a perforation for the valve stem 2 to pass through.

[0034] In this embodiment, the cross section of the valve seat 3 is "T" shape, its first part is ...

Embodiment 2

[0043] Such as Figure 4 shown in Example 1 using Figure 1 to Figure 3 Zero cold water water heater with multi-function valve shown.

[0044] The first water inlet 11 of the multi-function valve is connected to the circulating water pipeline 61 of the water heater, the second water inlet 12 is connected to the tap water pipeline 62, the water outlet 13 is connected to the water inlet pipeline 63 of the water heater, and the water inlet pipeline 63 of the water heater is provided with a circulation pump 7 , temperature sensor 64 and pressure sensor 65.

[0045] The circulation pump 7 , the motor 5 , the pressure sensor 65 and the temperature sensor 64 are all electrically connected to the control circuit 66 of the water heater.

[0046] All the other structures of the water heater are identical with the prior art.

[0047] The water flow control method of this zero cold water water heater is as follows:

[0048]When the water heater is performing the zero cold water progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com