Preparation technology of pig liver peptide powder

A preparation process, the technology of pig liver peptide powder, which is applied in the field of protein peptide preparation, can solve the problems that there are not many liver peptide powder technology methods and there are no patent reports, and achieve simple process flow, ensure stability and biological activity, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

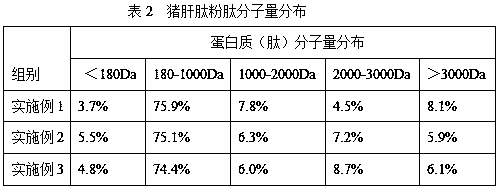

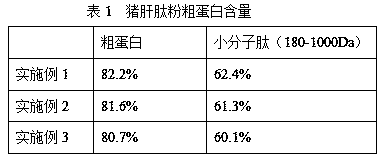

Examples

Embodiment 1

[0021] (1) Take 100kg of fresh pig liver that has passed the quarantine, remove the fascia, remove blood, wash, wash, add deionized water 3 times the weight of the pig liver, and homogenize with a homogenizer to obtain liver serum; ( 2) Heat the liver serum to 40°C, adjust the pH to 8.5, add 0.1% lipase to the total weight of the liver serum, stir for 5 minutes, stop stirring, keep warm for 60 minutes, then heat up to 95°C to inactivate the enzyme for 15 minutes , after cooling to room temperature, centrifuge at 4000rmp for 15 minutes, collect the precipitate, add deionized water 3 times the weight of the precipitate to the precipitate and stir evenly to obtain the defatted liver protein slurry; (3) raise the temperature of the defatted cerebroprotein slurry to 45°C, add 0.15% of the total weight of pig liver protease, adjust the pH value to 8.0, stir for 5 minutes, stop stirring, keep warm for 8 hours, heat up to 95°C to kill the enzyme for 15 minutes, cool to room temperature...

Embodiment 2

[0023] (1) Take 100kg of fresh pig liver that has passed the quarantine, remove the fascia, remove blood, wash, wash, add deionized water 3 times the weight of the pig liver, and homogenize with a homogenizer to obtain liver serum; ( 2) Heat the liver serum to 42°C, adjust the pH value to 8.8, add 0.08% lipase of the total weight of the liver serum, stir for 5 minutes, stop stirring, keep warm for 60 minutes, then heat up to 95°C to inactivate the enzyme for 15 minutes , after cooling to room temperature, centrifuge at 4000rmp for 15 minutes, collect the precipitate, add 4 times the weight of the precipitate to the deionized water and mix well to obtain the defatted liver protein slurry; (3) raise the temperature of the defatted liver protein slurry to 45°C, add 0.2% of the total weight of pig liver protease, adjust the pH value to 8.2, stir for 5 minutes, stop stirring, keep warm for 6 hours, heat up to 95 ° C to kill the enzyme for 15 minutes, cool to room temperature, and ob...

Embodiment 3

[0025] (1) Take 100kg of frozen fresh pork liver that has passed the quarantine, thaw the fascia, remove blood, wash, add deionized water twice the weight of the pig liver, and homogenize with a homogenizer to obtain liver serum; (2) Heat the liver serum to 45°C, adjust the pH value to 9.0, add 0.05% lipase to the total weight of the liver serum, stir for 5 minutes, stop stirring, keep warm for 60 minutes, heat up to 95°C to inactivate the enzyme for 15 minutes, cool After reaching room temperature, centrifuge at 4000rmp for 15 minutes to collect the precipitate, add deionized water 5 times the weight of the precipitate to the precipitate and stir evenly to obtain the defatted liver protein slurry; (3) raise the temperature of the defatted liver protein slurry to 50°C, add pig liver 0.3% of the total weight of protease, adjust the pH value to 8.5, stir for 5 minutes, stop stirring, keep warm for 4 hours, heat up to 95°C to kill the enzyme for 15 minutes, cool to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com