Machine pressed ground sesameseed oil and preparation method thereof

A technology for small grinding of sesame oil and sesame oil, applied in the field of oils and fats, can solve the problems of rising acid value of sesame oil, limiting the application of microwave technology, etc., and achieve the effects of reducing dosage, reducing acid value, and obvious flavor characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Clean the sesame seeds to remove impurities, and then wash with water to remove silt and shriveled particles. Spread the washed sesame seeds on the sieve until there is no more water dripping, and bake at 210°C for about 20 minutes. Add 40% water by weight to the fried sesame seeds, and the water temperature is 30°C. And stirred for 15min and left for 2h.

[0053] Microwave treatment is carried out on the sesame after adding water, the material layer thickness is 5cm, the conditions are: 7KW, time 5min, transmission speed 30cm / min.

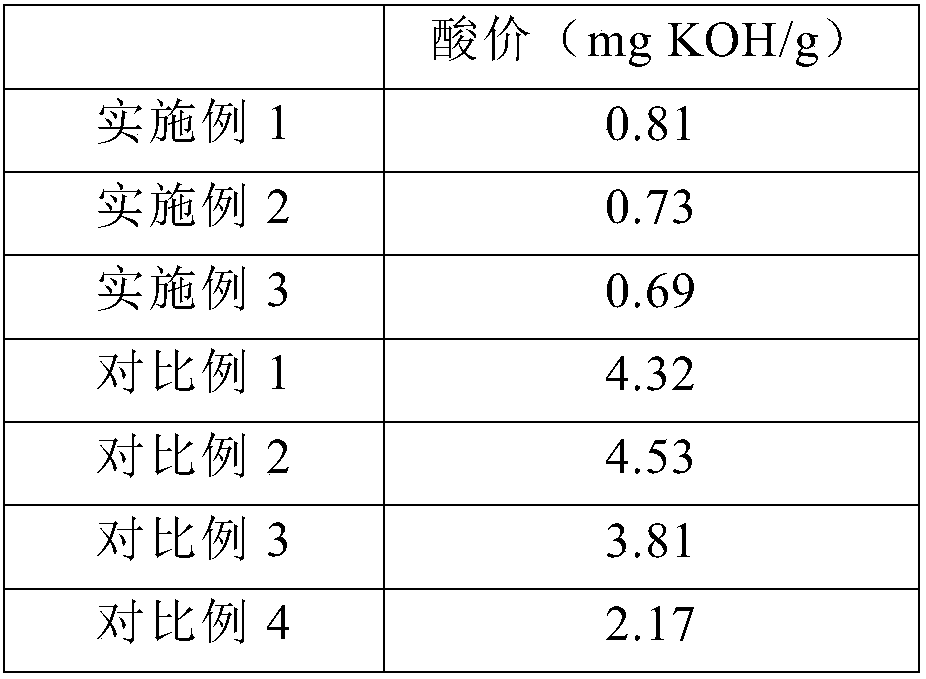

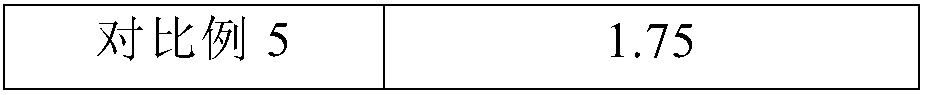

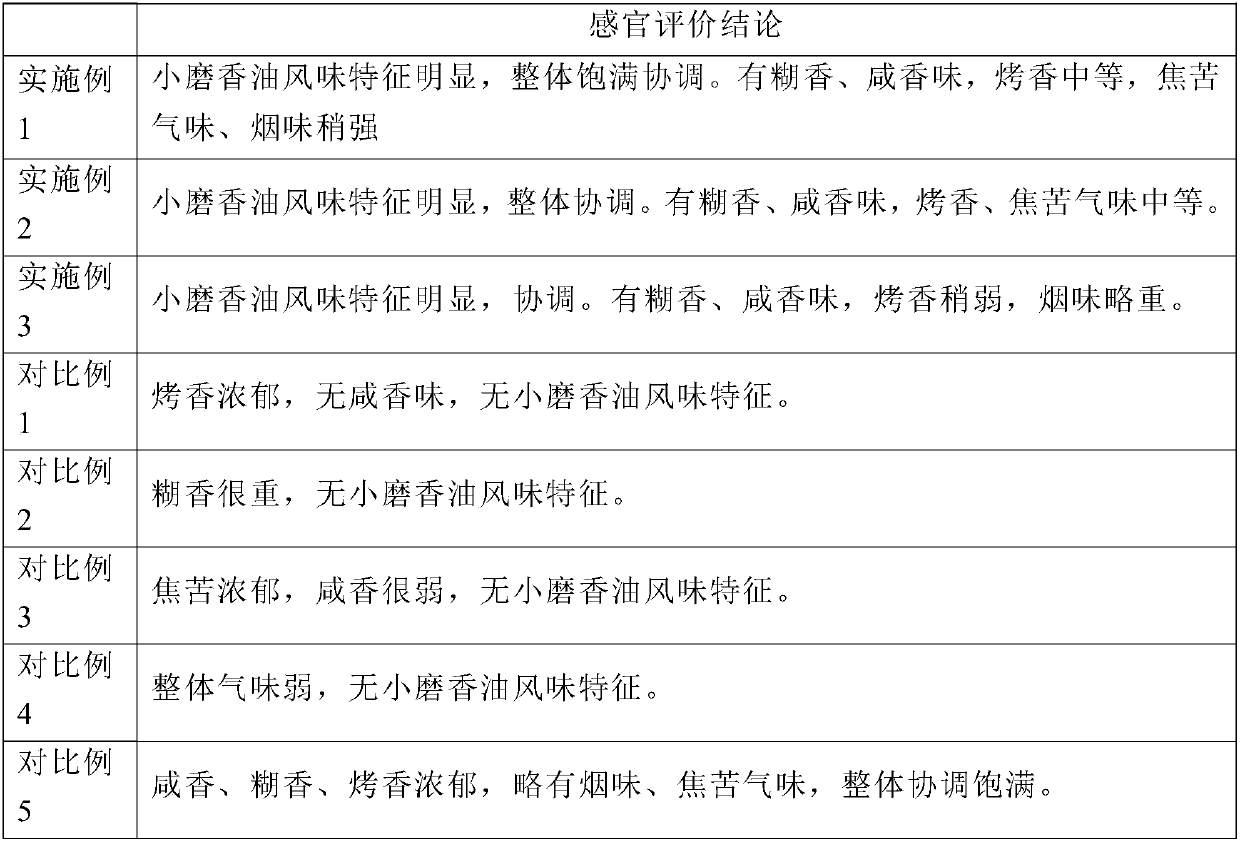

[0054] Oil was pressed by a screw press, and the crude oil was left to stand at 4°C for 3 days and filtered under normal pressure to obtain samples. Then evaluate the flavor and determine the acid value, wherein the acid value results are shown in Table 1, and the flavor evaluation results are shown in Table 2.

Embodiment 2

[0056] Clean the sesame seeds to remove impurities, and then wash with water to remove silt and shriveled particles. Spread the washed sesame seeds on the sieve until there is no more water dripping, then bake and fry at 230°C for about 15 minutes. Add 55% water by weight to the fried sesame seeds, and the water temperature is 50°C. And stirred for 10min and left for 1h.

[0057] Microwave treatment is carried out on the sesame after adding water, the material layer thickness is 1.5cm, the conditions are: 3KW, time 3min, transmission speed 90cm / min. Oil was pressed by a screw press, and the crude oil was left to stand at 4°C for 3 days and filtered under normal pressure to obtain samples. Then evaluate the flavor and determine the acid value, wherein the acid value results are shown in Table 1, and the flavor evaluation results are shown in Table 2.

Embodiment 3

[0059] Clean the sesame seeds to remove impurities, and then wash with water to remove silt and shriveled particles. Spread the washed sesame seeds on the sieve until there is no more water dripping, and bake at 190°C for about 25 minutes. Add 70% water by weight to the fried sesame seeds, and the water temperature is 90°C. And stirred for 25min and left for 3h.

[0060] Microwave treatment is carried out on the sesame after adding water, the material layer thickness is 3cm, the conditions are: 5KW, time 6min, transmission speed 60cm / min. Use a hydraulic oil press to extract the oil, and the crude oil is allowed to stand at 4°C for 3 days and filtered under normal pressure to obtain the sample. Then evaluate the flavor and determine the acid value, wherein the acid value results are shown in Table 1, and the flavor evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com