Highly-crosslinked acrylate copolymer as well as preparation method and application thereof as thickening agent

A technology of cross-linking acrylates and acrylates, applied in the direction of multi-color effect coatings, etc., can solve the problems of inability to protect multi-color paint, unable to meet the application, thickening efficiency defects, etc., and achieve good system compatibility and storage stability , to ensure the effect of suspension and stability, surface densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

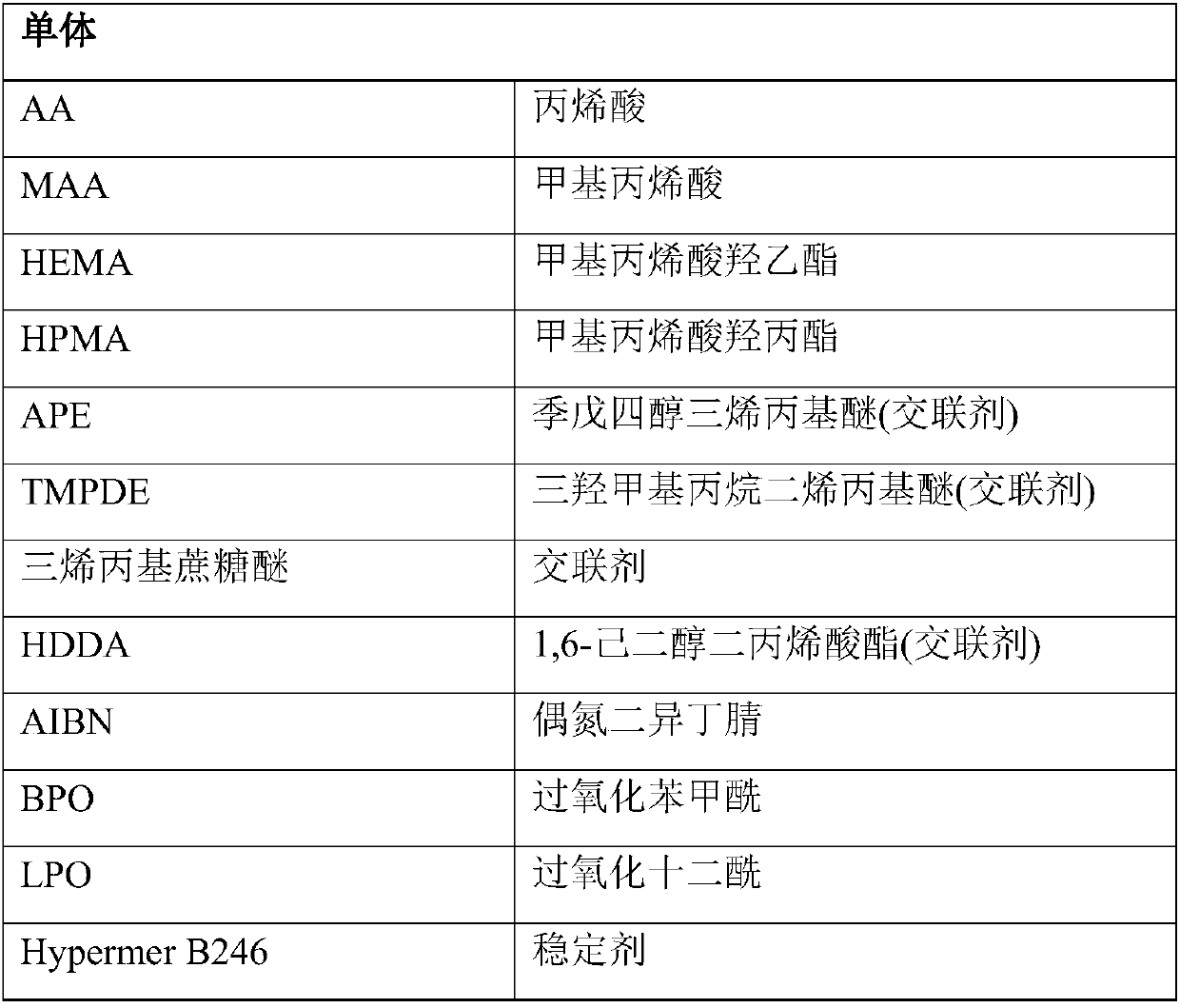

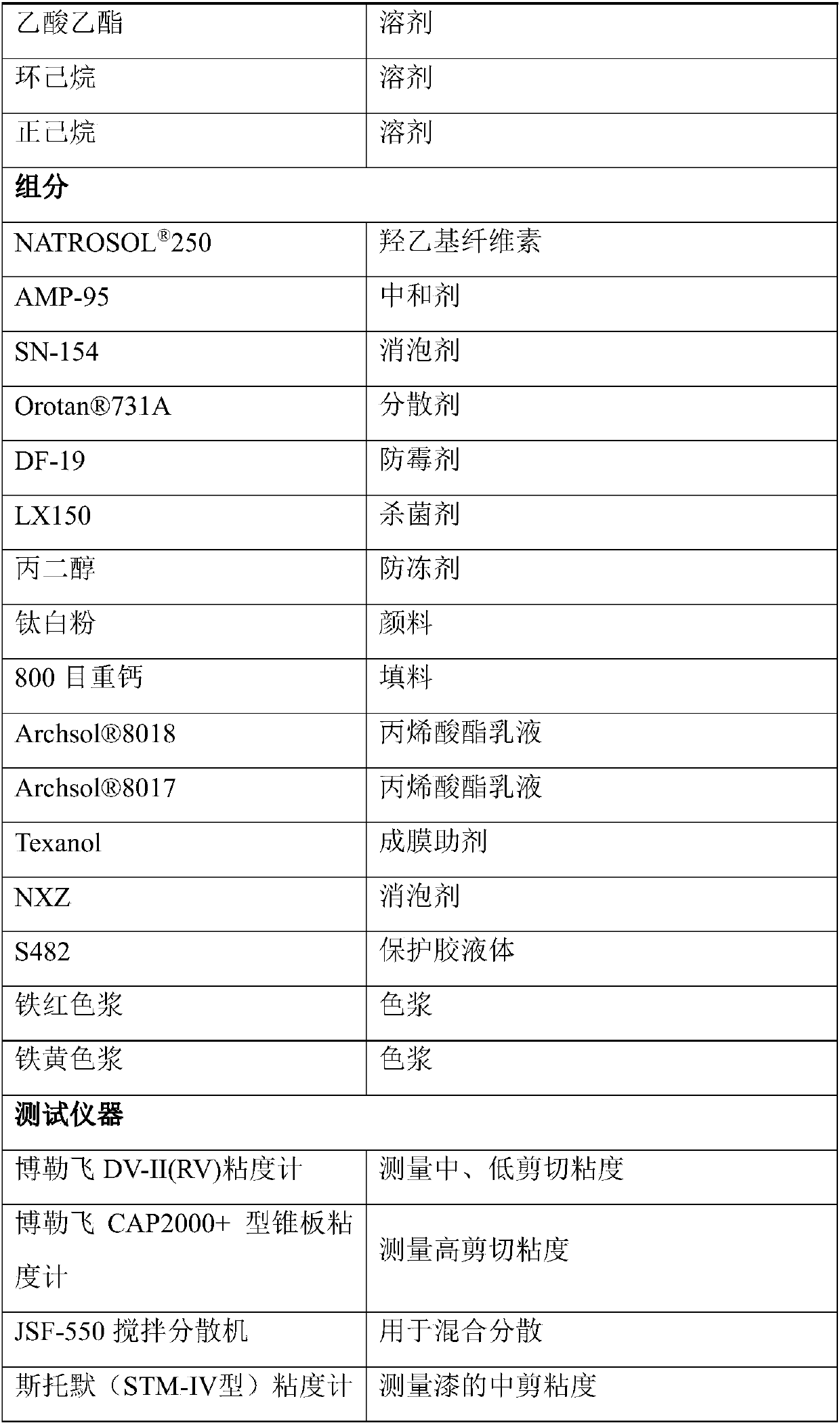

[0044] A highly cross-linked acrylic acid ester copolymer, the composition of its synthetic formula is as shown in Table 1:

[0045] Table 1

[0046] raw material Mass / g AAA 40 HEMA 40 TMPDE 0.82 Hypermer B246 0.16 AIBN 0.08 BPO 0.08 Cyclohexane 160 n-Hexane 160 ethyl acetate 400

[0047] The steps of the highly cross-linked acrylic copolymer synthesized by this formula are as follows:

[0048] 1) Add 160g of cyclohexane, 160g of n-hexane and 400g of ethyl acetate into a four-necked flask, connect the condenser, start stirring, and mix well;

[0049] 2) Add 40g monomer AA, 40g monomer HEMA, 0.82g crosslinking agent TMPDE, 0.16g stabilizer Hypermer B246 and 0.08g initiator AIBN and 0.04g initiator BPO into a four-necked flask until the initiator is completely dissolved. Bubble nitrogen for 20-30 minutes;

[0050] 3) Heating in a water bath, raising the temperature to 75°C, reacting for 3 hours, raising the ...

Embodiment 2

[0054] A highly cross-linked acrylic ester copolymer, its synthetic formula composition is as shown in Table 2:

[0055] Table 2

[0056]

[0057]

[0058] The synthesis steps of Example 2 are similar to those of Example 1, and will not be repeated here. The product C2 and sample A2 obtained according to this formula.

Embodiment 3

[0060] A highly cross-linked acrylic acid ester copolymer, its synthetic formula composition is as table 3:

[0061] table 3

[0062] raw material Mass / g AAA 25 MAA 15 HEMA 30 triallyl sucrose ether 0.3 TMPDE 0.4 Hypermer B246 0.14 AIBN 0.07 BPO 0.07 Cyclohexane 150 n-Hexane 150 ethyl acetate 330

[0063] The synthesis steps of Example 3 are similar to those of Example 1, and will not be repeated here. The product C3 and sample A3 obtained according to this formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com