Pretreatment method for high-salinity desulfurized wastewater of coal-fired power plant and system

A technology for desulfurization wastewater and coal-fired power plants. It is applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of reducing operating costs, removing impure products, and high process operating costs. Improve value-added effects and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

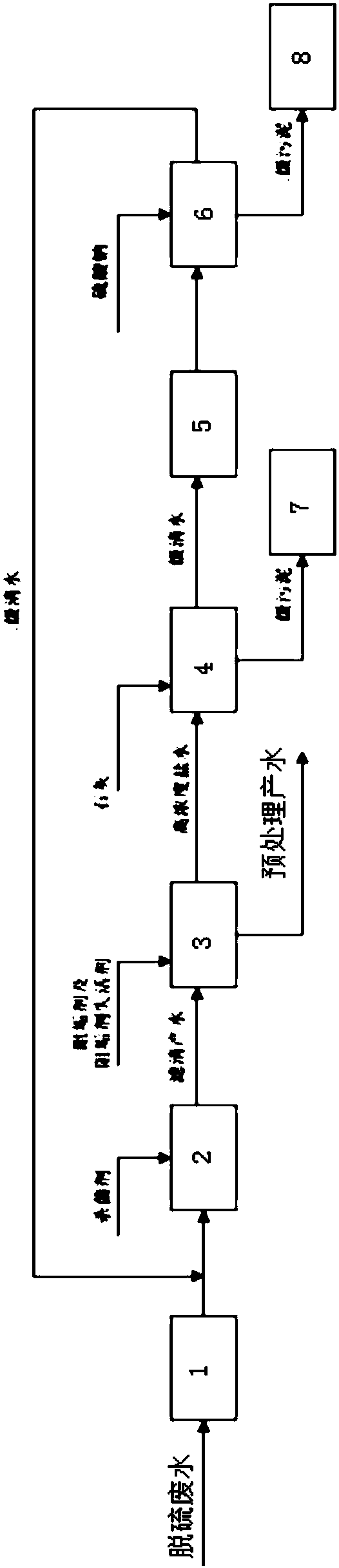

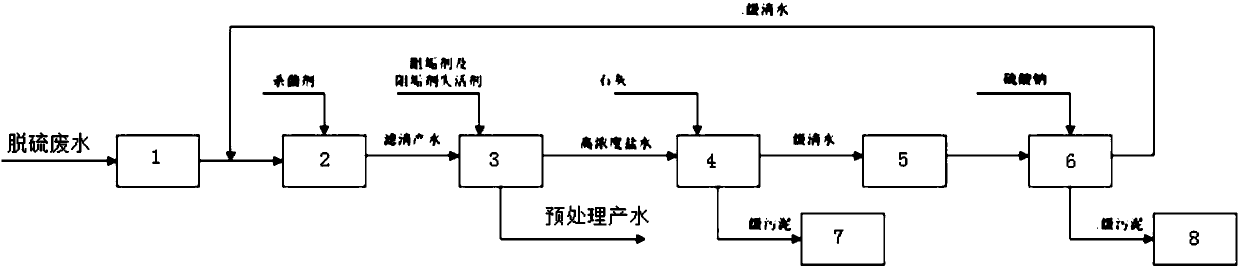

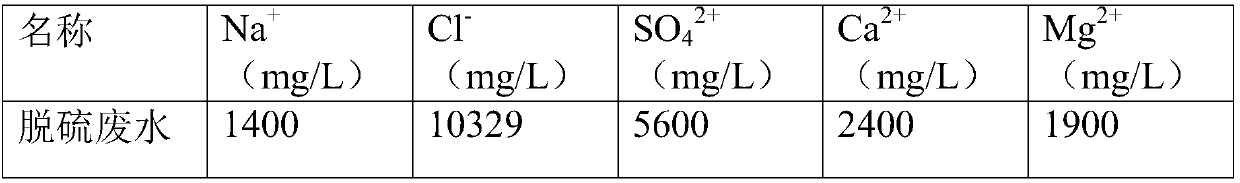

[0093] The high-salt desulfurization wastewater (flow rate 20t / h) of the coal-fired power plant whose composition is shown in Table 1 is passed into figure 1 In the first acidity adjustment unit of the high-salt desulfurization wastewater system of the coal-fired power plant shown, a hydrochloric acid solution with a concentration of 20% by weight is added to the first acidity adjustment unit to obtain a stock solution with a pH value of 7;

[0094] The secondary clear water returned by the stock solution and the downstream is passed into the filter unit, and the sodium hypochlorite of 5 mass ppm of the total amount of the stock solution and the secondary clear water is added, and ultrafiltration (ultrafiltration equipment provided by GE company) is carried out to obtain the filtered product water, The SDI value is 0.5; the weight ratio of stock solution and secondary clear water is 1.5:1;

[0095] Add hydrogen peroxide in an amount of 20 mass ppm of filtered product water to ...

Embodiment 2

[0102] The high-salt desulfurization wastewater (flow rate 20t / h) of the coal-fired power plant whose composition is shown in Table 1 is passed into figure 1 In the first acidity adjustment unit of the high-salt desulfurization wastewater system of the coal-fired power plant shown, a hydrochloric acid solution with a concentration of 20% by weight is added to the first acidity adjustment unit to obtain a stock solution with a pH value of 8;

[0103] The secondary clear water returned by the stock solution and the downstream is passed into the filter unit, and the sodium hypochlorite of 10 mass ppm of the total amount of the stock solution and the secondary clear water is added, and ultrafiltration (ultrafiltration equipment provided by GE company) is carried out to obtain the filtered product water, The SDI value is 0.8; the weight ratio of stock solution and secondary clear water is 3.5:1;

[0104] Add ferric chloride with an amount of 5 mass ppm of filtered product water to ...

Embodiment 3

[0111] The high-salt desulfurization wastewater (flow rate 20t / h) of the coal-fired power plant whose composition is shown in Table 1 is passed into figure 1 In the first acidity adjustment unit of the high-salt desulfurization wastewater system of the coal-fired power plant shown, a hydrochloric acid solution with a concentration of 15% by weight is added to the first acidity adjustment unit to obtain a stock solution with a pH value of 6;

[0112] The secondary clear water returned by the stock solution and the downstream is passed into the filter unit, and the hydrogen peroxide of 5 mass ppm of the total amount of the stock solution and the secondary clear water is added, and ultrafiltration (ultrafiltration equipment provided by GE company) is carried out to obtain the filtration product Water, the SDI value is 0.6; the weight ratio of stock solution and secondary clear water is 2:1;

[0113] Add ferric chloride that is 10 mass ppm of filtered product water to the filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com