Tooling and method for precisely controlling weld size of v-shaped bellows

A technology of precise control and weld size, applied in manufacturing tools, workpiece clamping devices, workbenches, etc., can solve the problems of high manufacturing cost, low product qualification rate, and difficulty in controlling the weld width of bellows diffusion welding. Achieve the effect of reducing production cost, improving qualification rate, and accurately controlling the size of diffusion welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

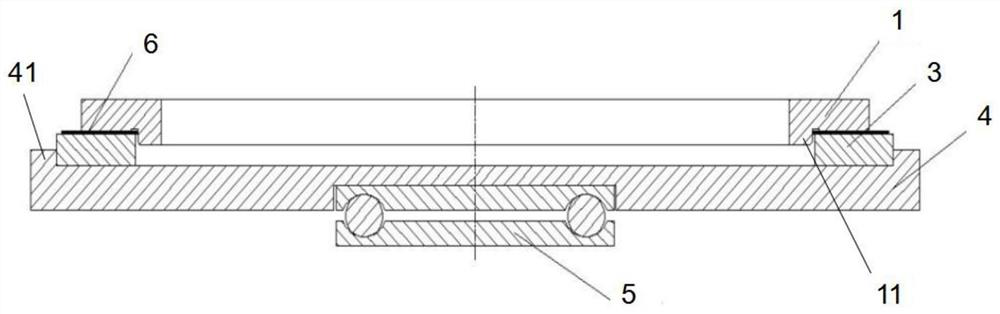

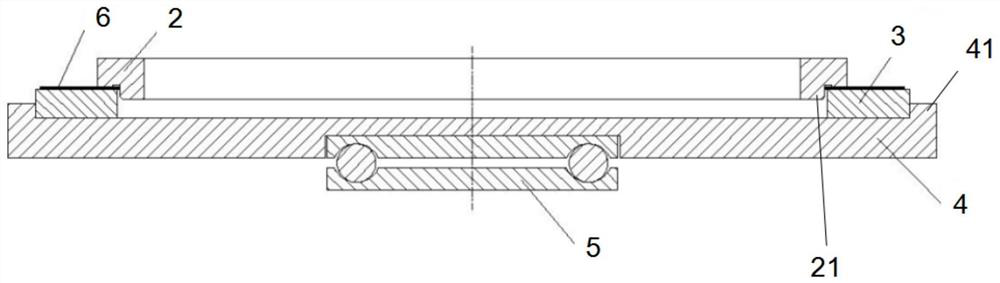

Embodiment 1

[0033] to combine Figure 1-2 Describe this embodiment. This embodiment provides a tooling for precisely controlling the weld size of a V-shaped bellows. The tooling includes a large dial 1, a small dial 2, a base 3, a tray 4 and a rotating bearing 5; wherein: The large dial 1 is circular, and the bottom surface of the large dial 1 is provided with a circle of the first circular ring protrusion 11 along its inner diameter edge; the small dial 2 is circular, and the small dial 2 The bottom surface of the bottom surface is provided with a circle of second annular protrusions 21 along its inner diameter edge; the inner diameter of the small dial 2 is equal to the inner diameter of the large dial 1, and the outer diameter of the small dial 2 is smaller than that of the large dial The base 3 is circular, and the inner diameter of the base 3 is greater than the inner diameter of the small dial 2, and the inner diameter of the base 3 is less than the outer diameter of the small dial ...

Embodiment 2

[0052] This embodiment also provides a method for accurately controlling the weld size of the V-shaped corrugated pipe by using the above-mentioned tooling, which is carried out according to the following steps:

[0053] 1) Clean the surface of the ring-shaped sheet to remove stains, and apply a layer of protective glue on the surface of the ring-shaped sheet;

[0054] 2) Put the plate processed in step 1) on the base (3), press the large dial (1) on the top of the plate, rotate the tray (4), and follow the outer contour of the large dial (1) Use a carving knife to score on the glued surface, remove the large dial (1), press the small dial (2) on the top of the sheet, rotate the tray (4), and follow the outer surface of the small dial (2). The outline is scored on the glued surface with a carving knife;

[0055] 3) Do not repeat the engraving when engraving;

[0056] 4) Control the force of the engraving knife to ensure that the protective glue is cut off without scratching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com