High-speed stirrer for stirring putty

A stirrer, fast technology, applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

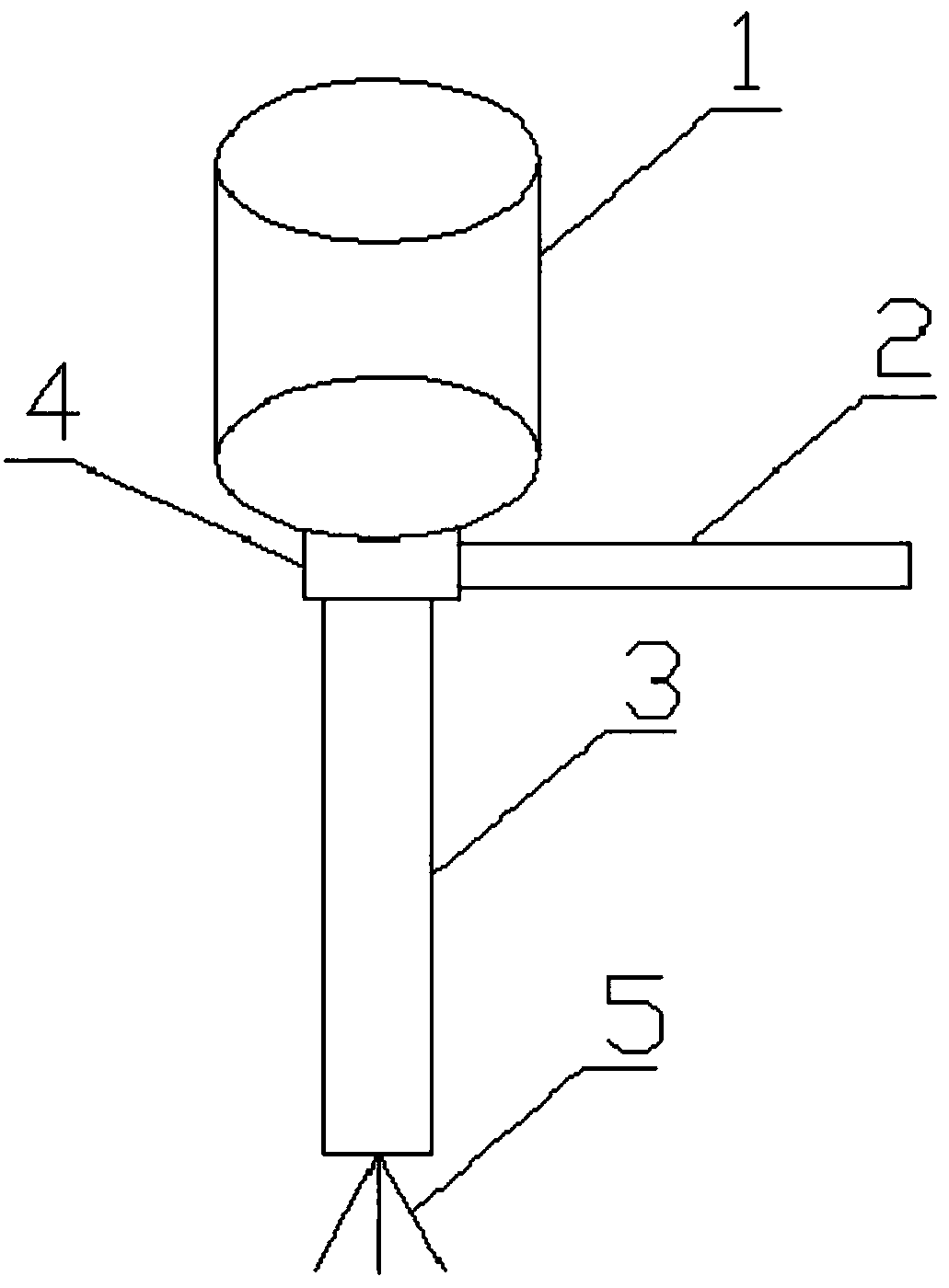

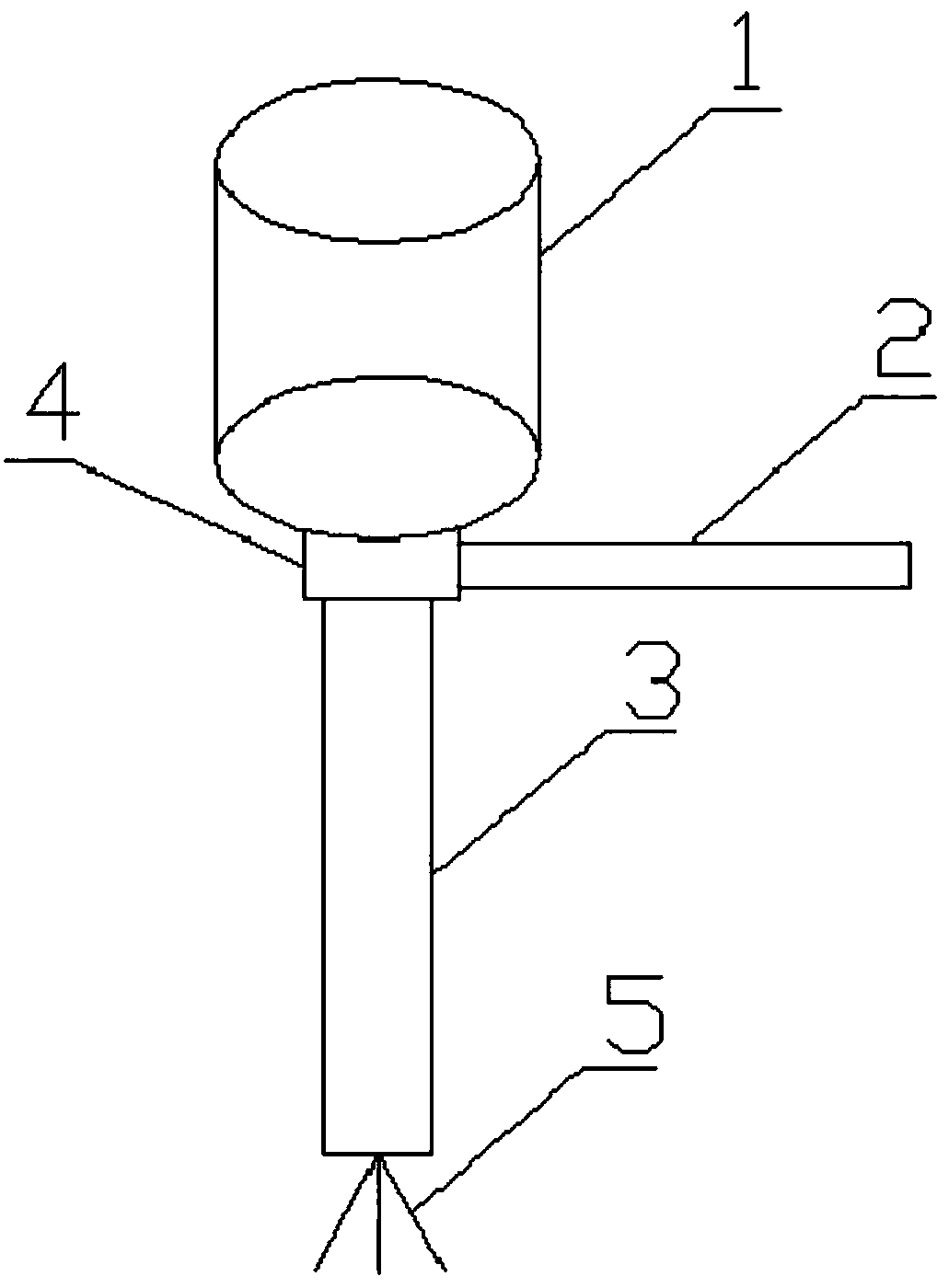

[0020] A fast mixer for mixing putty, its main feature is that it includes a motor 1, a handle 2, a stirring rod 3, a connecting part 4, and a stirring claw 5, the motor 1 and the stirring rod 3 are connected through the connecting part 4, and the handle 2 is installed on the connecting part On the right side of the component 4, the stirring claw 5 is arranged at the bottom of the stirring rod 3.

[0021] Further, the motor 1 adopts a three-phase asynchronous variable-frequency motor.

[0022] Further, the inner material of the handle 2 is alloy steel, and the outer is covered with pearl cotton, which has a shockproof effect.

[0023] Further, the stirring rod 3 is made of 304 stainless steel.

[0024] Further, the connecting part 4 is made of PE material, which has good wear resistance and impact resistance, good chemical corrosion resistance and stress crack resistance.

[0025] Further, the stirring claws 5 adopt 12 wire rod stirring claws to ensure uniform stirring.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com