Strawberry picking auxiliary device

An auxiliary device, strawberry technology, applied in the fields of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of uneven distribution of strawberry ripening, damage to strawberries, and bacterial infection of fruits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

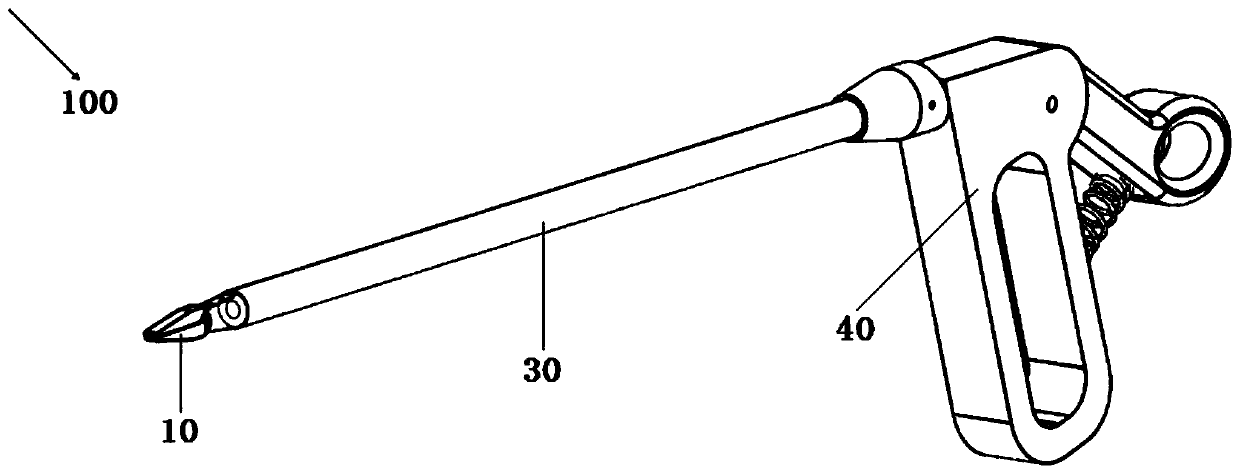

[0031] figure 1 It is a schematic diagram of the overall structure of the strawberry picking auxiliary device in the embodiment of the present invention.

[0032] Such as figure 1 As shown, a strawberry picking auxiliary device 100 of this embodiment includes: a chuck assembly 10, a hinge assembly 20, a rod assembly 30, and a handle assembly 40.

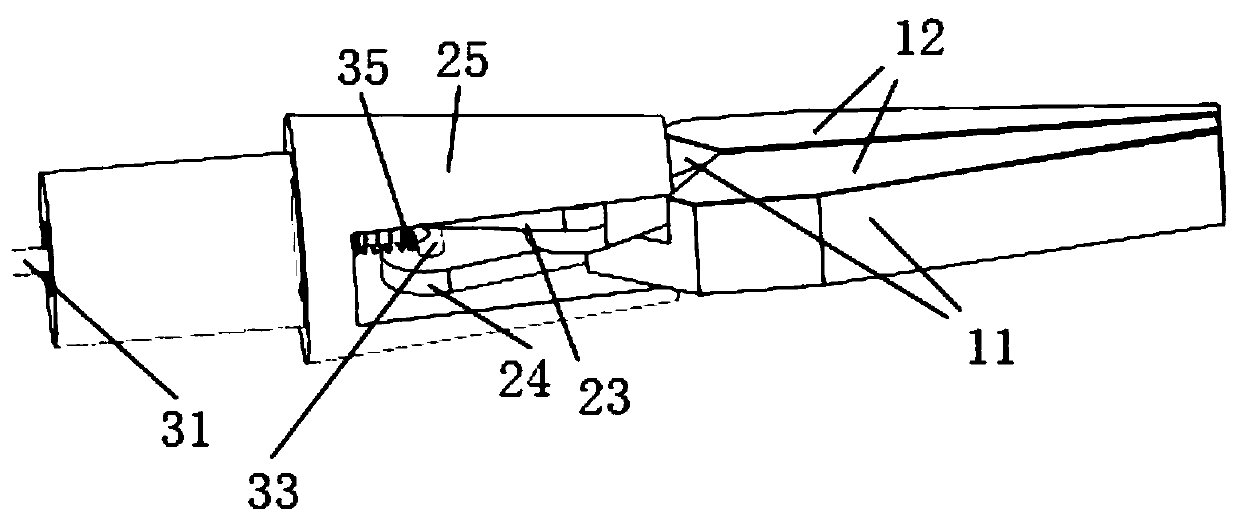

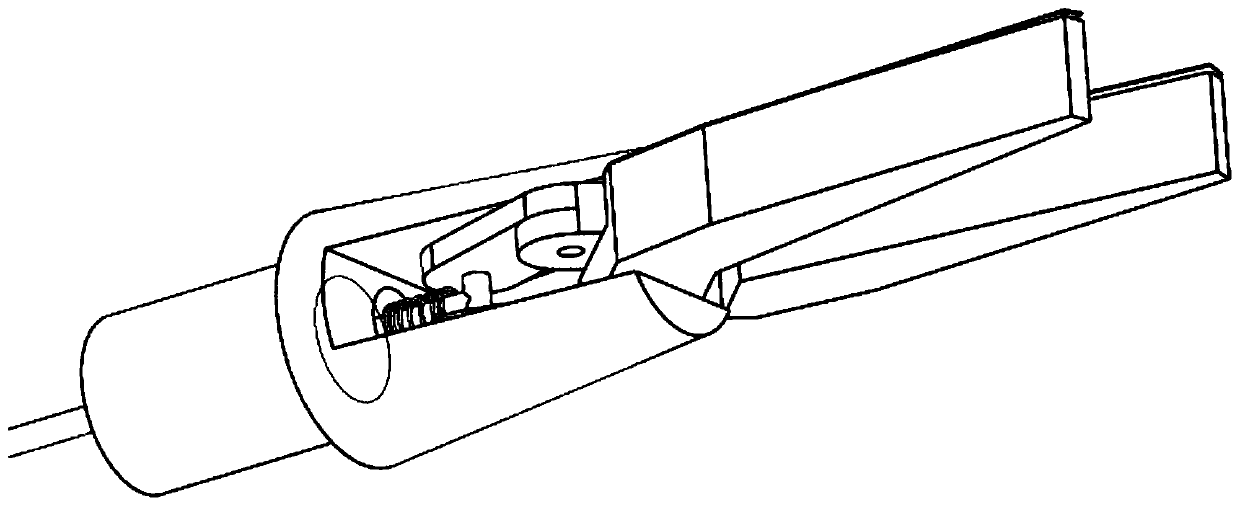

[0033] figure 2 It is a schematic diagram of the closed state of the clamp head of the strawberry picking auxiliary device including the chuck assembly and the hinge assembly in the embodiment of the present invention, image 3 It is a schematic diagram of the open state of the clamp head including the chuck assembly and the hinge assembly of the strawberry picking auxiliary device in the embodiment of the present invention, Figure 4 It is a schematic diagram of the open state of the clamp head including the chuck assembly and the hinge piece of the strawberry picking auxiliary device in the embodiment of the present invention, Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com