Discharging tray for rubber track

A rubber crawler and discharge tray technology, which is applied in the field of discharge trays for rubber crawlers, can solve the problems that the discharge tray cannot be adjusted, production demand cannot be adjusted, etc., and achieve reduced work intensity and danger, high practical performance, and reduced production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

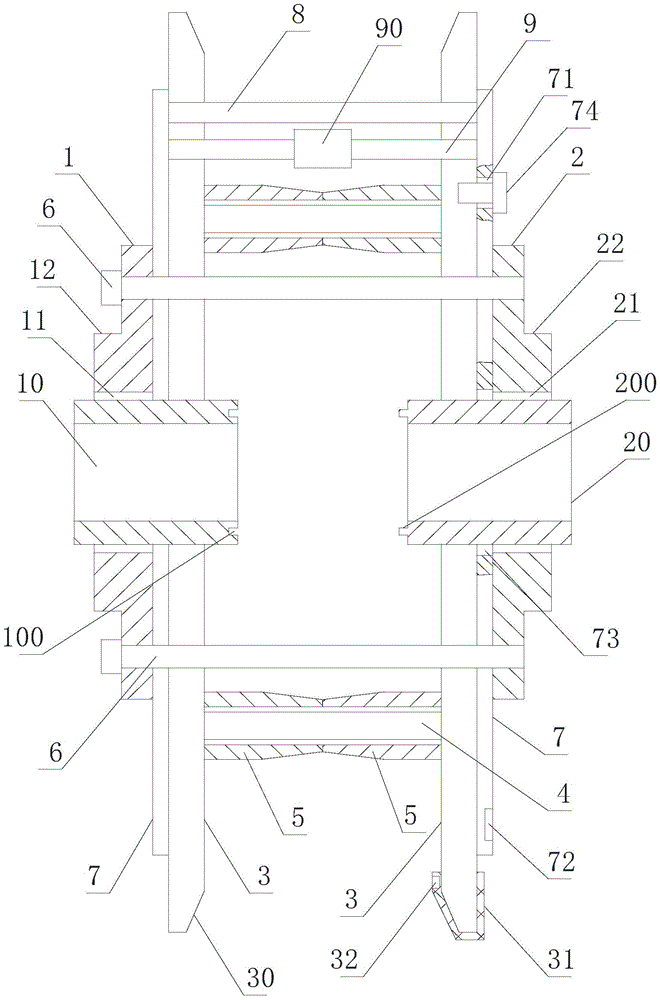

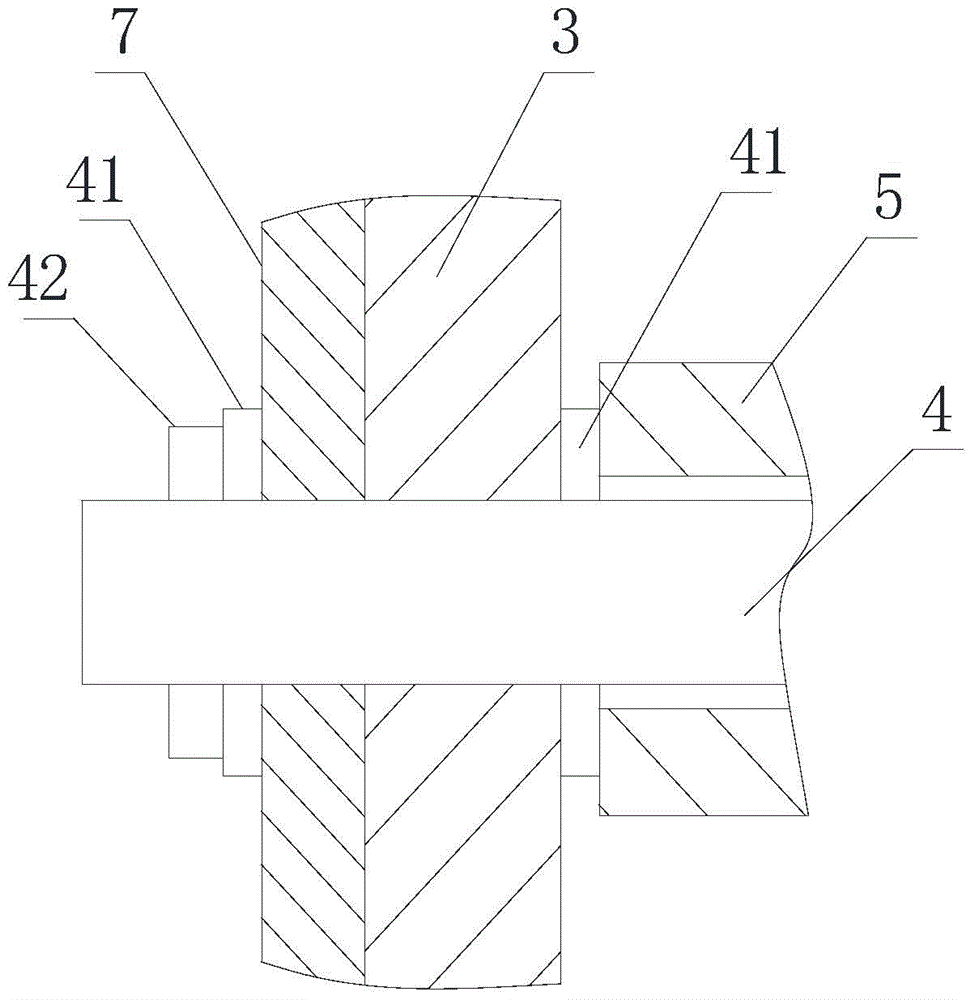

[0017] Such as figure 1 , figure 2 , image 3 As shown, a discharge tray for rubber tracks includes a left baffle 1, a right baffle 2, and several pieces are arranged between the left baffle 1 and the right baffle 2 for adjusting the left baffle 1 and the right baffle 2. The screw rod 6 of spacing between, described left baffle plate 1 and right baffle plate 2 are provided with the threaded hole that matches with screw rod 6, and the inner side wall of described left baffle plate 1 is provided with first axle sleeve 10, and described The middle part of the left baffle 1 is provided with a first installation hole 11 installed with the first bushing 10, and the first bushing 10 is penetrated in the first installation hole 11, and the inner side wall of the right baffle 2 is provided with There is a second shaft sleeve 20, and the middle part of the right baffle plate 2 is provided with a second mounting hole 21 connected with the second shaft sleeve 20, and the second shaft s...

Embodiment 2

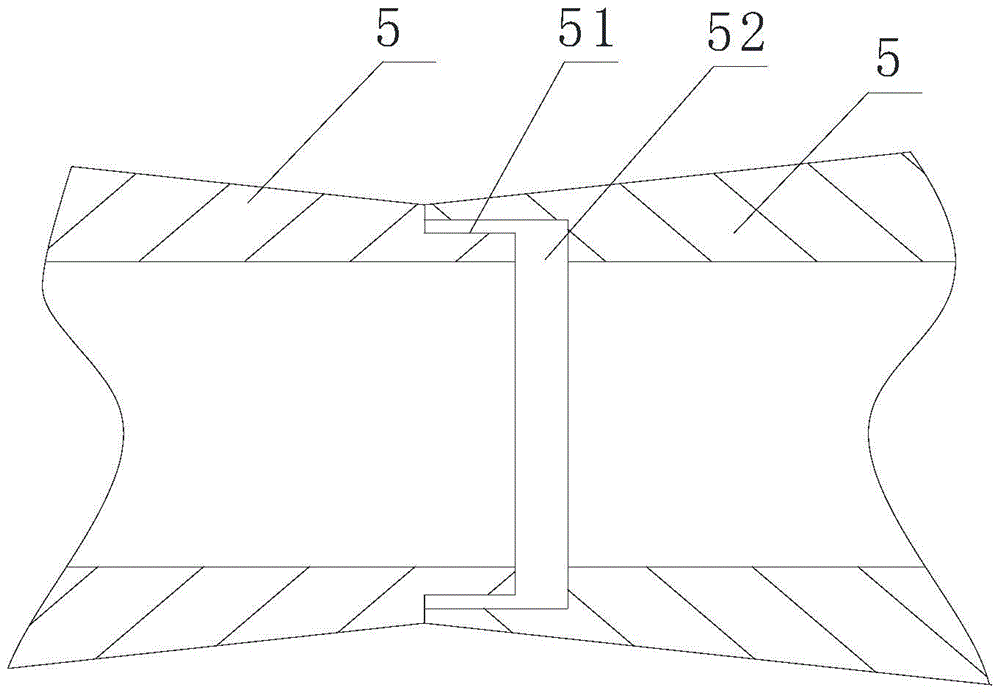

[0019] A discharge pan for a rubber track as described in Embodiment 1, this embodiment has the following differences: as Figure 4 As shown, the guide roller 5 is one, and the middle part of the guide roller 5 is provided with an inwardly arranged groove 55, the bottom end of the groove 55 is arc-shaped, and the two sides of the groove 55 Both ends are provided with a downward-sloping inclined part, which is easy to install and has a good rotation effect. The setting of the inclined part is convenient for discharging and has good practical performance.

[0020] When the unwinding tray is rewinding, adjust the distance between the left baffle 1 and the right baffle 2 through the screw 6 to adjust the receiving area, so as to rewind according to the amount of production. When rewinding, turn the unwinding tray The rubber crawler is wound along the circle formed by the guide roller 5 in sequence. When discharging, the discharge tray is fixedly connected to the discharge shaft th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com