Damping pipeline system based on friction energy dissipation

A technology of friction energy consumption and pipeline system, which is applied in the direction of pipeline supports, pipe components, pipes/pipe joints/pipe fittings, etc., to achieve low cost, wide range of application objects, and reduce seismic acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0027] 1. The structure of the damping pipeline system

[0028] 1. Overall

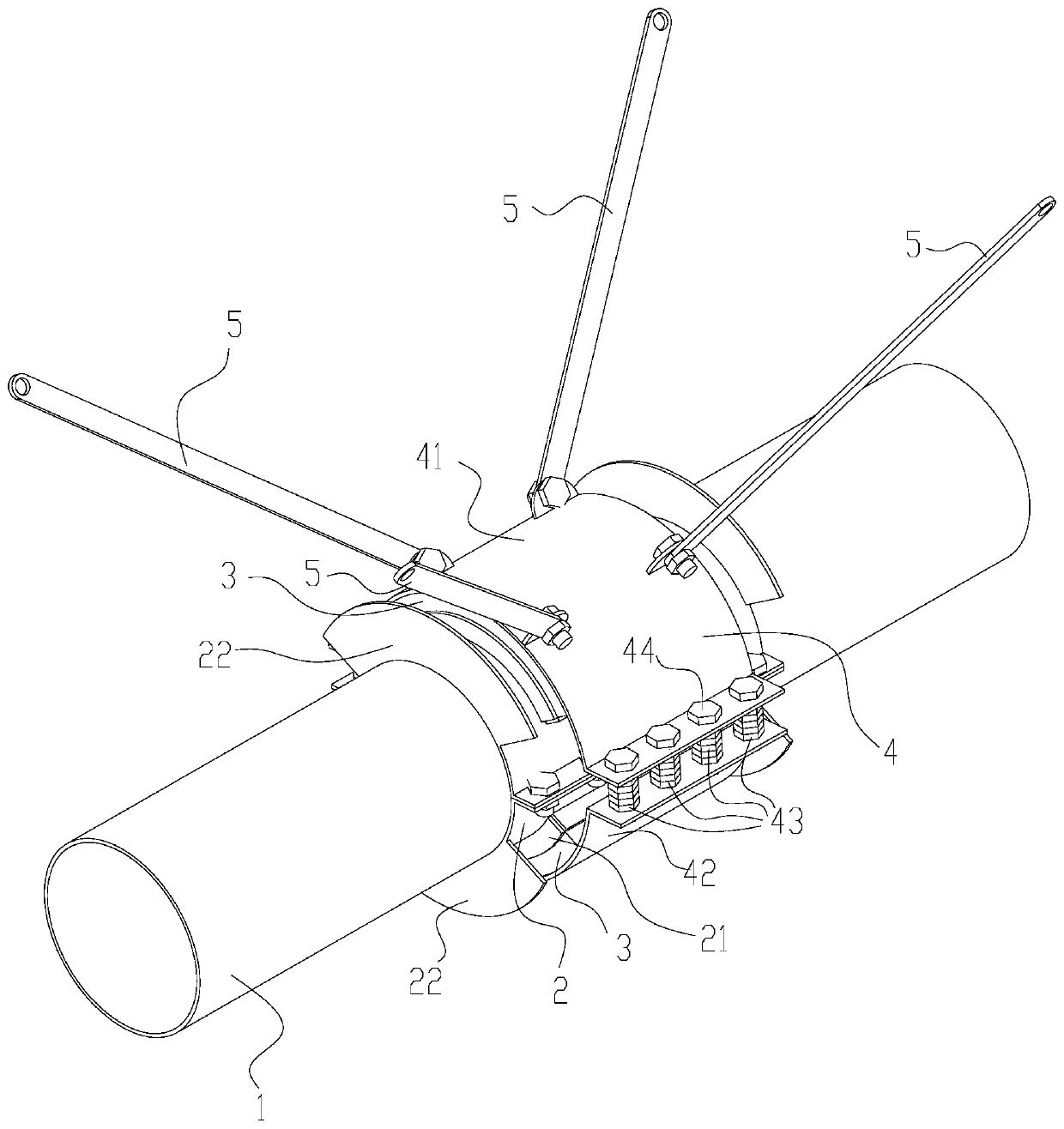

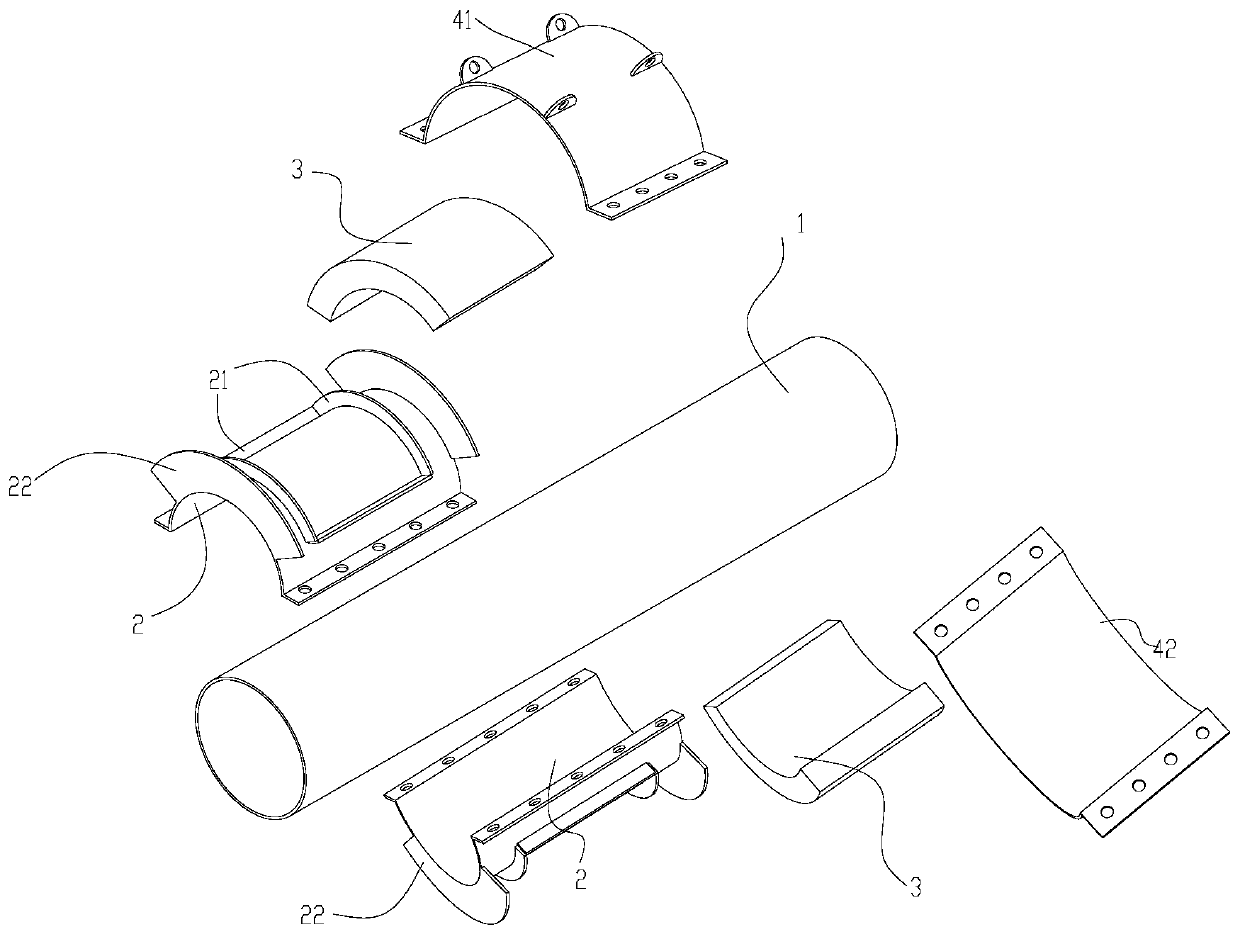

[0029] Such as Figure 1 to Figure 5 As shown, a damping pipeline system based on frictional energy dissipation includes a pipeline 1, an inner pipe clamp 2, a frictional energy dissipation layer 3, an outer pipe clamp 4 and an anti-seismic support 5;

[0030] The inner pipe clamp 2 is composed of two annular sub-pipe clamps, the two sub-pipe clamps are connected and fixed on the pipeline 1 by bolts, and a frictional energy dissipation layer 3 is set between the inner pipe clamp 2 and the outer pipe clamp 4, and the anti-seismic support 5 is fixedly installed on the outer pipe clamp 4, and the end of the anti-seismic support 5 is provided with a mounting hole for mounting on the structural member, and the pipeline system is fixed on the structural member through the anti-seismic support 5. The outer pipe clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com