Assembly type self-resetting friction energy dissipation support member with variable prestress

A technology of frictional energy consumption and supporting components, which is applied to building components, protective buildings/shelters, and earthquake resistance, and can solve the problems of inability to adjust the prestress of supporting components, high cost of shape memory alloys, and poor deformation capacity of prestressed tendons And other problems, to achieve good economic benefits, low cost, easy to repair and replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

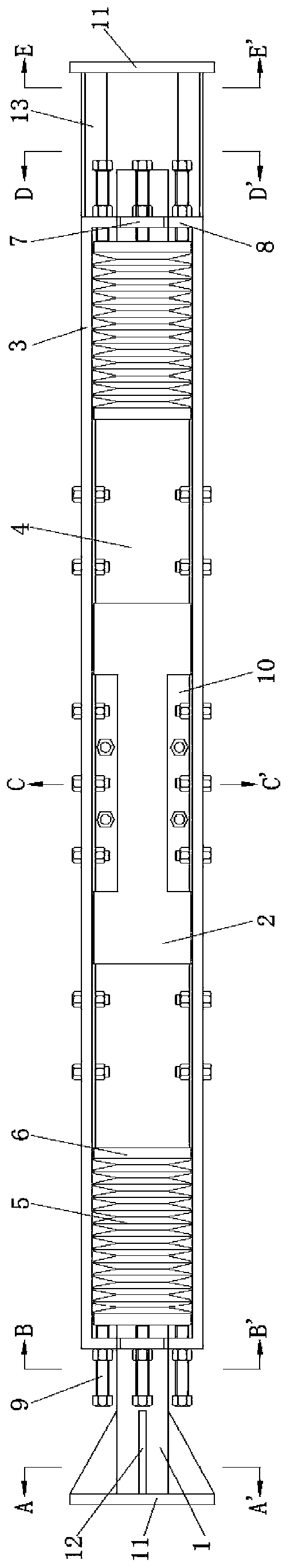

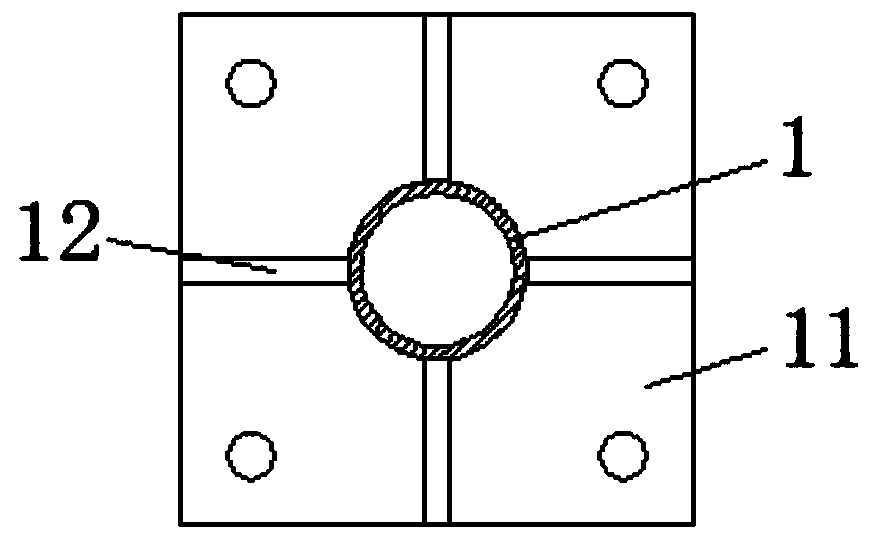

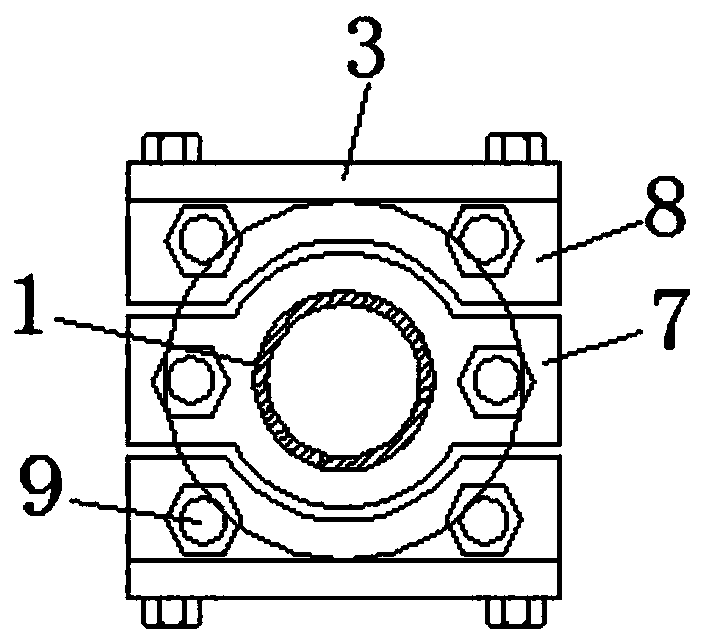

[0040] Example 1, such as Figure 1-10 As shown, the present invention provides a technical solution: an assembled variable prestressed self-resetting friction energy dissipation support member, including a circular steel pipe 1, a rectangular steel pipe 2, a cover plate 3, a channel steel 4, a disc spring 5 and Friction angle steel 10, rectangular steel pipe 2 has a notch in the middle of the long side of the section at both ends, circular steel pipe 1 is set on the inner side of rectangular steel pipe 2 and welded and fixed with rectangular steel pipe 2 at the notch of rectangular steel pipe 2 to form an inner pipe ;

[0041] Disc spring 5 is provided with two and is respectively socketed on the two ends of circular steel pipe 1, and the outer side of circular steel pipe 1 is respectively sleeved with baffle plate 6 at two ends of disc spring 5, and baffle plate 6 and circular steel pipe 1 There is a sliding connection between them, and a reset mechanism is formed between t...

Embodiment 2

[0048] Example 2, such as Figure 11 As shown, two support mechanisms of the present invention are formed into a "herringbone" shape, and are installed in the interlayer position of a certain span of the frame structure through bolts, and the displacement between the upper and lower floors is used to push the support mechanism to deform and consume energy, and its upper end is connected On the gusset plate at the bottom of the frame beam span of the upper layer, its lower end is connected with the gusset plate next to the column foot of the lower layer of the frame column, and the adjustment of the prestress of the support mechanism is completed by tightening or loosening the jacking bolt 9, which is convenient To meet the needs of supporting force of different floors, when the supporting member is subjected to the force generated by the displacement between the upper and lower floors, the cover plate 3 of the outer pipe and the friction angle steel 10 will slide relative to ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com