u-t slope type variable friction damper

A damper, variable friction technology, applied in protected buildings/shelters, building types, buildings, etc., to solve problems such as bolt-spring preload loss, insufficient hysteresis curve, and inelastic deformation of plates , to achieve the effect of easy acquisition, flexible use and large selection space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

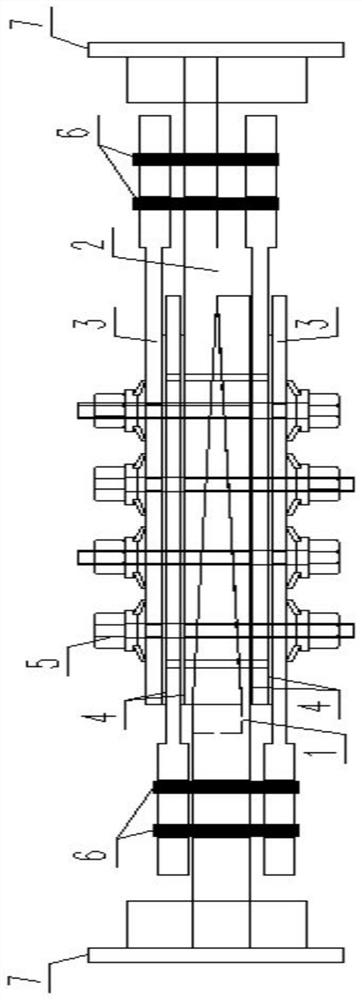

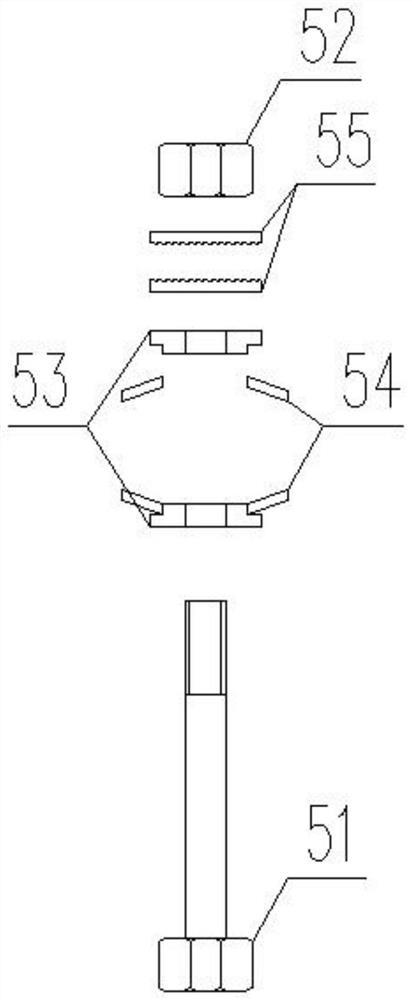

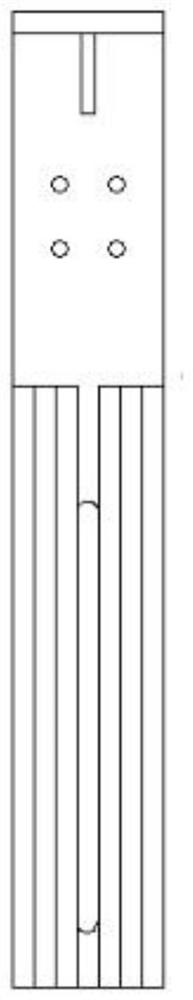

[0052] Such as Figure 1-12 As shown, the mechanism is divided into an L part group and an R part group, and the L part group includes a steel plate part (2) with a U-type slope surface, two flat steel plate parts (3) and are pinned to each other by a connecting pin key (6). together (no constraints in the thickness direction); the R part group includes a steel plate part (1) with a T-type slope, 2 flat steel plate parts (3) and are pinned together by connecting pins (6) (no constraints in the thickness direction ); there is a friction material interlayer (4) on the plane contact surface between the L and R parts groups (that is, all the contact surfaces except the contact surface between the part (1) and the part (2), through- The bolt-spring pretensioner (5) compresses the L and R part groups together.

[0053] When the L part group and the R part group start from the initial position along the length direction (that is, the top slope of the T rib is completely attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com