Paving method of assembled base asphalt pavement

An asphalt pavement, combined technology, applied in the direction of roads, roads, coagulation pavement paved on site, etc., to achieve the effect of tight bonding, reducing attenuation rate, and avoiding bottom voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

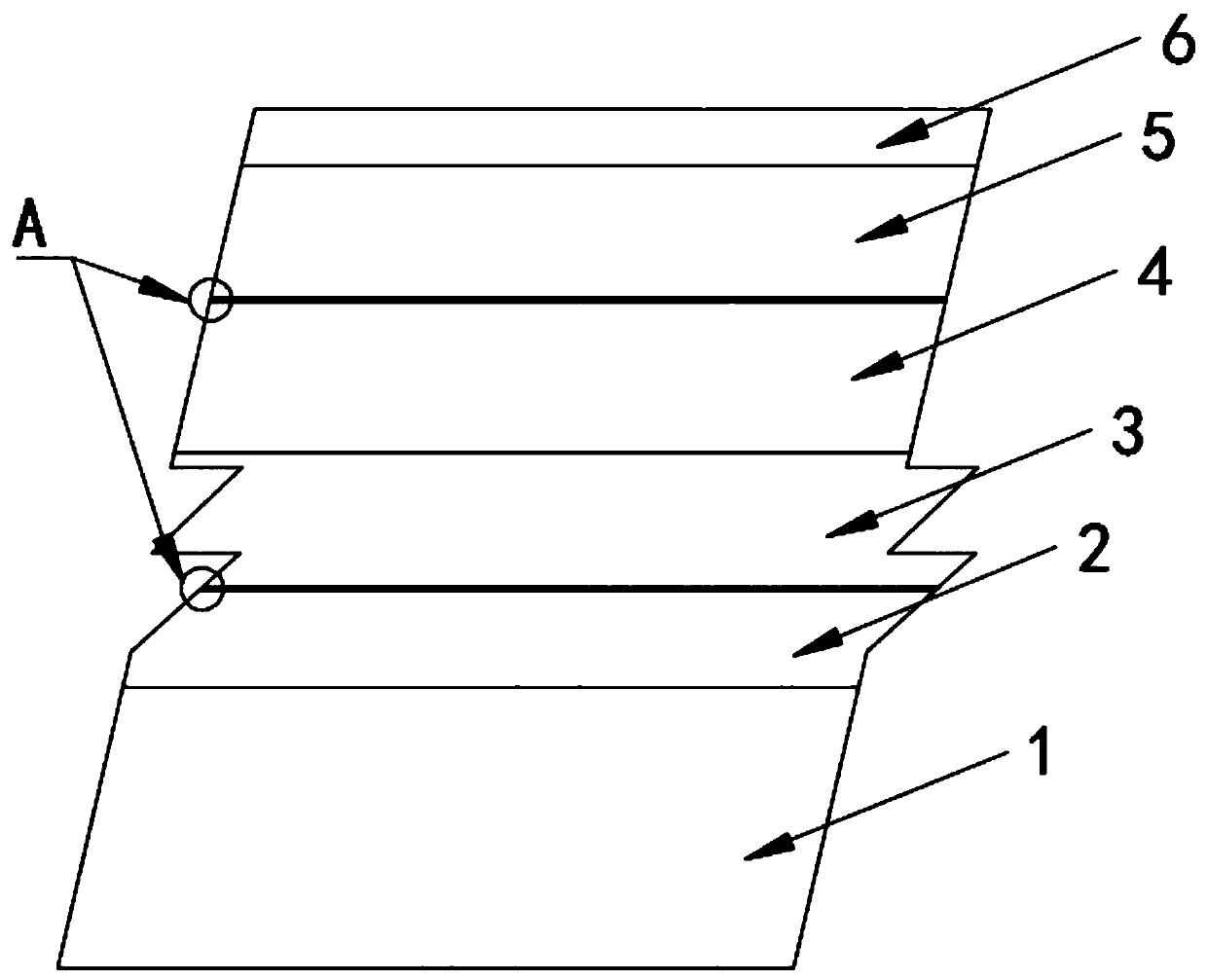

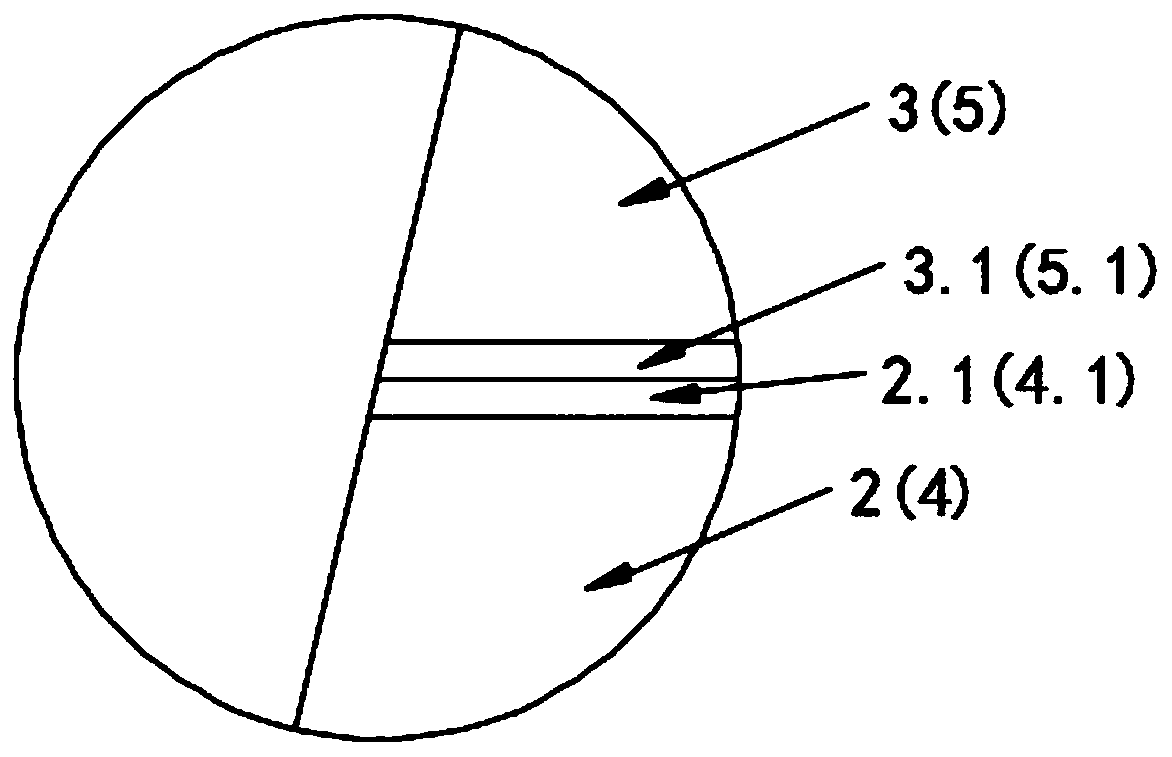

[0051] as attached figure 1 As shown, the combined base asphalt pavement paving method of this embodiment consists of an asphalt mixture viscoelastic anti-fatigue cushion layer 3, a cement-stabilized gravel lower base 4, an asphalt-stabilized upper base 5, and an asphalt surface layer 6. Asphalt mixture viscoelastic anti-fatigue buffer cushion layer 3, cement-stabilized crushed stone lower base layer 4, asphalt-stabilized upper base layer 5, and asphalt surface layer 6 are directly paved on the roadbed from bottom to top. The roadbed includes a soil foundation 1 and a cement-improved soil layer 2 on top of the soil foundation 1 .

[0052] 1. Cement improves soil

[0053] 1. Raw material indicators

[0054]Cement-improved soil layers should use gravel soil with better grading as subgrade filler, with a maximum particle size of 53 mm, a soil uniformity coefficient of 13, a liquid limit of 35, a plasticity index of no more than 10, and a soil with an organic matter content of l...

experiment example

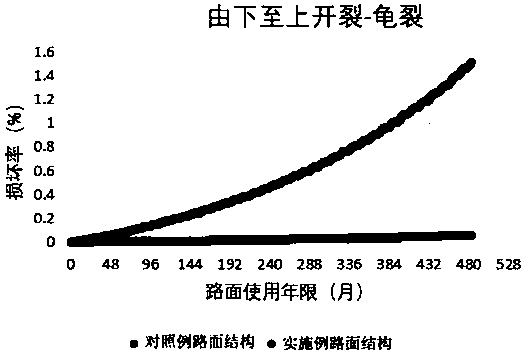

[0116] Using the current asphalt pavement design specification method and the MEPDG mechanical experience method to carry out structural checking and analysis on the two pavements of Example 1 and Comparative Example:

[0117] 1. Based on the American MEPDG calculation and analysis method

[0118] Select the measured structure and material parameters, as attached image 3 As shown, the cracking rate of the traditional pavement structure (comparative example) from the bottom of the pavement to the top of the pavement increases exponentially with time:

[0119] y=0.0505e 0.008x Where y is the cracking rate and x is the time (months).

[0120] And the pavement structure of the present invention is by the equation of time-varying smooth rate of cracking from the bottom of the pavement to the top of the pavement: y=0.0001x-0.0064 where y is the cracking rate, and x is the time (number of months), and the probability of cracking is almost zero.

[0121] 2. Calculation and analys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com